Brake Hydraulic System Components

Summary

TLDRThis video script provides an in-depth exploration of hydraulic braking systems, focusing on master cylinders, brake lines, and related components. It explains how master cylinders generate hydraulic pressure, the role of primary and secondary circuits in tandem master cylinders, and the function of components like pistons, seals, and compensating ports. The script also discusses the mechanics of brake calipers, wheel cylinders, and hydraulic pressure transfer, highlighting the importance of brake fluid management and the failure safety mechanisms built into these systems. It emphasizes the complexity and precision behind the components that ensure reliable braking performance in vehicles.

Takeaways

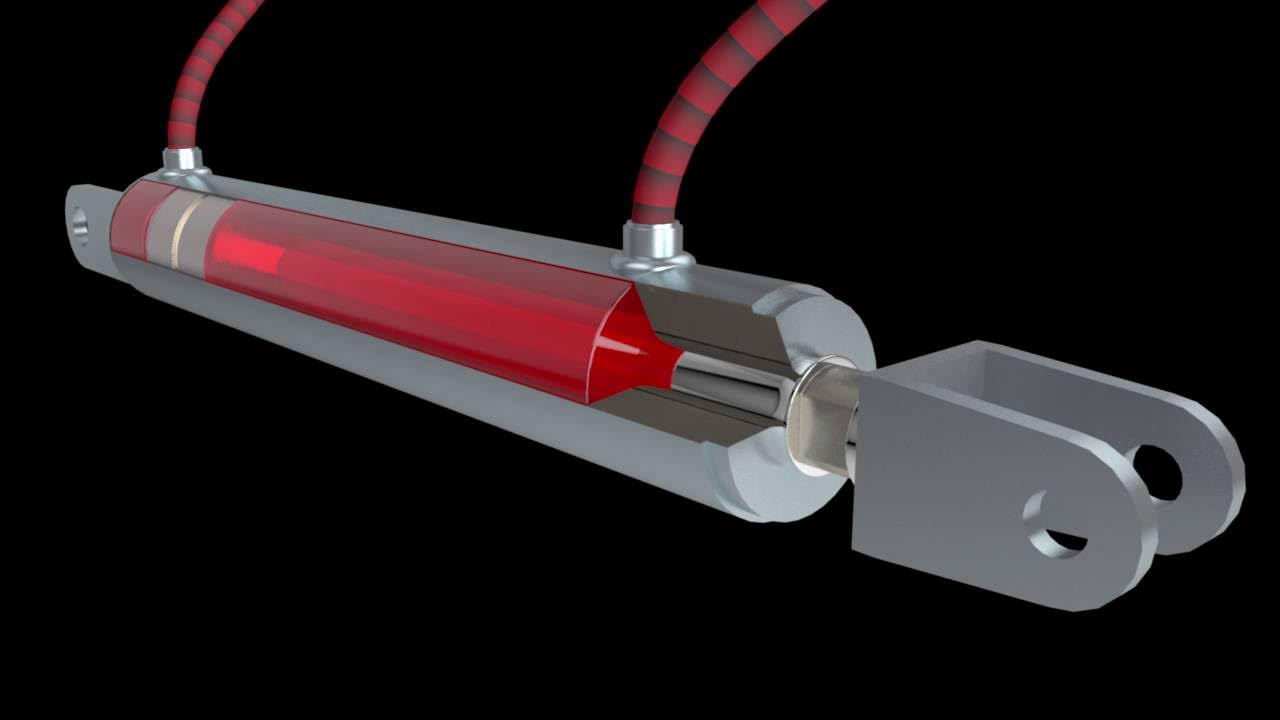

- 😀 The hydraulic braking system consists of three key components: master cylinder, brake lines, and slave cylinder, with the master cylinder being central to the entire system.

- 😀 The master cylinder converts the motion of the brake pedal into hydraulic pressure, utilizing brake fluid and pistons for this transformation.

- 😀 Single piston master cylinders have two seals, the primary cup and secondary cup, which prevent fluid leakage and maintain pressure.

- 😀 The compensating port adjusts for fluid volume changes due to temperature variations, ensuring that brake fluid is effectively managed during operation.

- 😀 When the brake pedal is released quickly, the recuperation process allows brake fluid to return to the reservoir and prevents the creation of a vacuum in the system.

- 😀 The residual line pressure valve ensures that brake fluid is held at slightly above atmospheric pressure when the system is not in use, preventing air entry and fluid leakage.

- 😀 Tandem master cylinders feature two hydraulic circuits that provide redundancy; if one fails, the other can still function to stop the vehicle.

- 😀 The master cylinder's reservoir contains brake fluid and features a diaphragm to prevent air contact, which helps prevent moisture absorption that could damage the system.

- 😀 The primary and secondary pistons in a tandem master cylinder pressurize the system by moving forward and transmitting fluid pressure to different brake circuits.

- 😀 In newer ABS-equipped vehicles, portless master cylinders are used, which lack a compensating port in the secondary circuit and utilize a valve-controlled supply port to manage fluid pressure.

- 😀 Brake lines are critical for transferring fluid pressure from the master cylinder to the wheel brake assemblies, with steel tubes and rubber hoses designed for durability and flexibility.

Q & A

What are the three basic parts of a hydraulic braking system?

-A hydraulic braking system consists of a master cylinder, brake lines, and a slave cylinder. The master cylinder pushes fluid through the lines, and the slave cylinder moves when fluid pressure is applied.

What is the function of the master cylinder in a hydraulic braking system?

-The master cylinder stores brake fluid and converts the motion of the brake pedal into hydraulic pressure, which is then transmitted through the brake lines to activate the braking system.

What materials are commonly used to manufacture the master cylinder?

-Most master cylinders are made from cast iron or aluminum, which are durable and resistant to corrosion.

What is the purpose of the compensating port in the master cylinder?

-The compensating port adjusts for changes in the volume of brake fluid due to temperature fluctuations, allowing fluid to return to the reservoir when the brake pedal is released.

How does the primary piston in a single piston master cylinder function?

-When force is applied to the piston by the push rod, the primary piston seals the hydraulic pressure in the cylinder, preventing fluid from leaking out.

What happens during the recuperation process in the master cylinder?

-During recuperation, when the brake pedal is released quickly, the brake fluid can't return to the cylinder fast enough. Fluid passes from the reservoir into the working chamber through small holes in the piston, preventing a vacuum from forming.

What is the purpose of the residual line pressure valve in the master cylinder?

-The residual pressure valve maintains slight pressure in the brake lines to prevent air from entering and to stop fluid from leaking out of the wheel cylinders.

What is the difference between a single piston and a tandem master cylinder?

-A single piston master cylinder has one hydraulic circuit, while a tandem master cylinder has two separate hydraulic circuits, allowing for continued braking if one circuit fails.

What is the role of the secondary piston in a tandem master cylinder?

-The secondary piston in a tandem master cylinder is acted upon by hydraulic pressure from the primary circuit and helps apply pressure to the secondary hydraulic circuit, ensuring continued braking if one circuit fails.

How do brake lines connect the master cylinder to the wheel brake assemblies?

-Brake lines, made of double-walled steel tubing, transfer fluid pressure from the master cylinder to the wheel brake assemblies. They are secured with mounting brackets and clips to prevent damage from vibration.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Brake Apply System [service Brake & Parking Brake]

Pilihan Komponen Upgrade Rem RCB | Gridoto Tips

Sistem Rem Mobil | Toyota Brake System Simulator: Komponen, Fungsi, dan Cara Kerja

Rem ngempos? ini cara kerja Master Cylinder Brake

Aircraft Systems - 07 - Hydraulic System

8 Komponen Rem Cakram + Fungsinya

5.0 / 5 (0 votes)