The Modernization Journey - Keynote Audio Presentation

Summary

TLDRThis video delves into how Industry 4.0 technologies are transforming manufacturing and business strategies. It covers the challenges of supply chain disruptions, the role of automation and advanced analytics in enhancing sustainability and product efficiency, and the importance of data in driving transformation. The presentation emphasizes the need for continuous adaptation, strategic investment, and partnership to navigate digital maturity and modernize operations, ultimately enabling organizations to stay competitive, reduce waste, and optimize energy consumption while embracing a sustainable future.

Takeaways

- 😀 The supply chain crisis has forced manufacturers to redesign products and qualify new suppliers to meet customer needs.

- 😀 Modernizing outdated technologies is crucial as older hardware is rapidly reaching the end of its lifecycle.

- 😀 Industry 4.0 helps drive sustainability by improving product efficiency, reducing waste, and optimizing energy consumption.

- 😀 Robotics, automation, and machine learning are key to improving production efficiency and reducing the need for human labor.

- 😀 IoT and big data can be used to track energy usage and optimize production schedules, contributing to sustainability efforts.

- 😀 Industry 4.0 enables companies to support the circular economy by improving product lifecycle management, recycling, and sustainable material usage.

- 😀 Data is at the core of Industry 4.0, allowing real-time analysis to drive better decision-making and innovation.

- 😀 The use of smart devices, AI, and advanced communication networks supports more flexible and responsive production systems.

- 😀 Industry 4.0 is an ongoing journey, requiring continuous adaptation and innovation, not a one-time event.

- 😀 Companies need a clear strategy and plan for leveraging Industry 4.0 technologies to stay competitive and meet their goals.

- 😀 Organizations must invest in both technology and human resources to maximize the benefits of Industry 4.0 and remain competitive.

Q & A

What is the primary focus of the conversation in this video?

-The primary focus of the video is on the impact of Industry 4.0 technologies on businesses, particularly in terms of supply chain challenges, sustainability, and modernization strategies.

How has the supply chain crisis affected manufacturing companies?

-The supply chain crisis has led to the discontinuation of certain parts and products, forcing companies to redesign and re-qualify suppliers for new components. This makes it necessary for businesses to adapt and find alternatives to maintain production.

What role does modernization play in addressing supply chain issues?

-Modernization allows companies to adapt to changing technologies and overcome supply chain disruptions by upgrading systems, ensuring better efficiency, and mitigating the risks of outdated components.

What are the primary reasons companies are adopting sustainability strategies?

-Companies are adopting sustainability strategies to increase efficiency, add brand value, meet customer demands, gain a competitive advantage, and attract talent.

How do Industry 4.0 technologies support sustainability?

-Industry 4.0 technologies support sustainability by improving product efficiency through automation, optimizing production schedules to reduce waste, monitoring energy usage in real-time, and enabling a circular economy by tracking products through their lifecycle.

How does the use of robotics contribute to sustainability in manufacturing?

-Robotics contribute to sustainability by automating repetitive and routine tasks, improving accuracy in production processes, reducing human labor, and enhancing overall production efficiency.

What are some ways Industry 4.0 helps reduce energy consumption?

-Industry 4.0 helps reduce energy consumption by utilizing IoT and big data to monitor and control energy usage in real time, identifying areas for improvement and potential energy savings.

How can Industry 4.0 technologies aid in reducing carbon footprints?

-Industry 4.0 can help reduce carbon footprints by optimizing transportation, logistics, and supply chain management, minimizing the need for transportation and thus lowering emissions.

Why is data central to the Fourth Industrial Revolution?

-Data is central to the Fourth Industrial Revolution because it enables real-time analysis and decision-making, optimizes production processes, drives innovation, and allows for more responsive and adaptable production systems.

What is the importance of having a clear strategy in digital transformation?

-A clear strategy is essential in digital transformation because it ensures that companies can fully leverage emerging technologies, adapt to new trends, and continuously evaluate and adjust their strategies to remain competitive.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Entrevista Miercoles 02 Abril

Как играют лучшие опорные полузащитники.#1 Жоржиньо, Брозович, Пьянич, Паредес, Матич, Берг.

O que é a indústria? | Indústria de A a Z - (Ep. #1)

Chapter 04 Kuliah Musik PGSD Unesa

How to DESTROY All The Popular Formations in FM23! (Works For FM24)

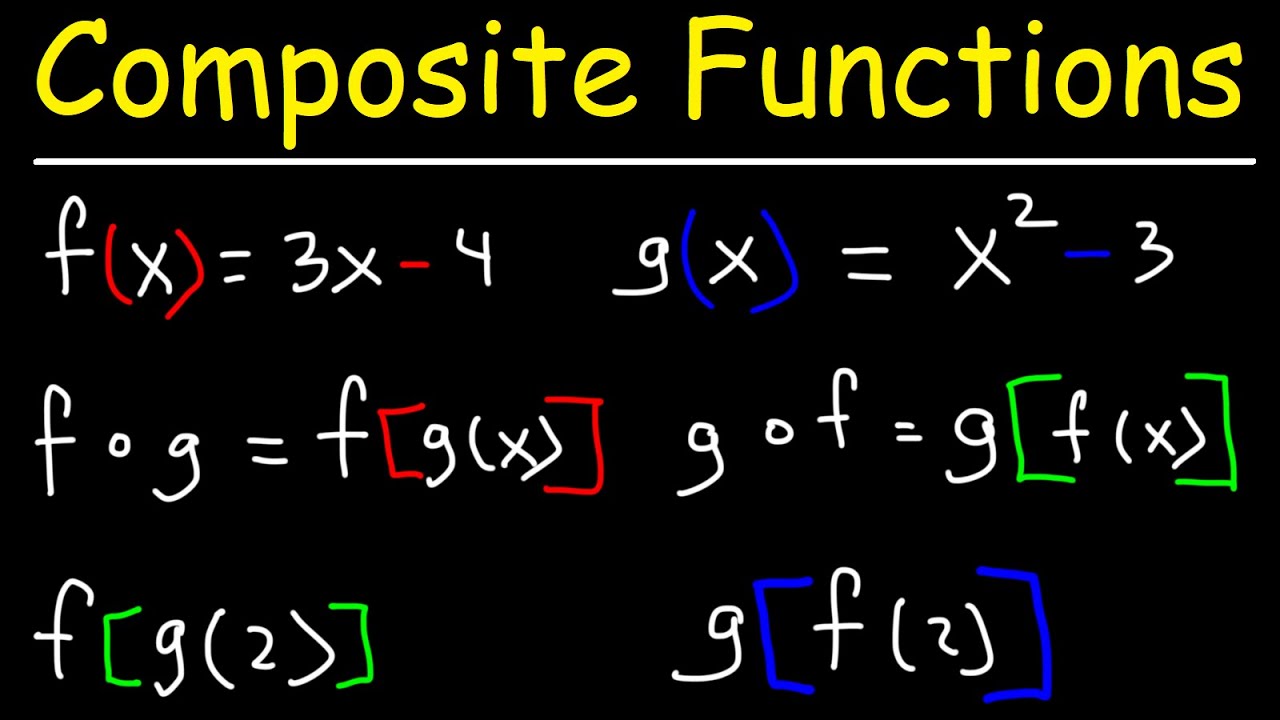

Composite Functions

Godot 4 ARPG Tutorial - Lesson 3: Player Animations & Camera Setup

5.0 / 5 (0 votes)