Lead Battery Recycling Process

Summary

TLDRThis video script explains the entire process of recycling lead automobile batteries, emphasizing their sustainability. It outlines how lead, plastic, and acid components are separated and reused, with each part going through a detailed recycling process. Reclaimed materials, such as lead and plastic, are transformed into new battery parts, while reclaimed acid is neutralized and used in various household goods. The video concludes by highlighting how lead batteries are one of the most recycled consumer products, demonstrating an environmentally-conscious technology that starts a cycle of reuse and recycling in the automotive industry.

Takeaways

- 😀 99% of all lead batteries are recycled, making them the most recycled consumer good in the United States.

- 😀 Almost all vehicles on the road in the U.S. are powered by lead batteries, and many electric vehicles use them as well.

- 😀 Spent batteries are shipped to an EPA-regulated smelter where they are processed and recycled.

- 😀 Lead and plastic are separated using water, with lead sinking and plastic floating, for further recycling.

- 😀 Reclaimed lead is smelted, refined, and reused in new batteries, and this process can be repeated indefinitely.

- 😀 Reclaimed plastic from batteries is cleaned, melted, and used to create new battery cases.

- 😀 Reclaimed acid from batteries is neutralized, and the sodium sulfate byproduct is used in household goods like laundry detergents.

- 😀 Recycled lead ingots are melted and made into battery grids, which are essential for the battery’s power delivery system.

- 😀 The grids are coated with a paste made of lead oxide and water, which forms the active material in the battery plates.

- 😀 After assembly, the batteries are charged, tested, and ready for shipment, starting the cycle of use and reuse once again.

Q & A

What is the environmental impact of recycling lead batteries?

-Recycling lead batteries has a minimal environmental impact due to the high recycling rates, with 99% of lead batteries being recycled. This makes them one of the most recycled consumer goods in the United States.

What role do lead batteries play in the modern automotive industry?

-Nearly all vehicles on the road in the United States are powered by lead batteries, and many electric vehicles also contain lead batteries, highlighting their importance in powering modern transportation.

How are spent lead batteries processed after being returned to retailers?

-After being returned to retailers, spent lead batteries are shipped to a smelter, where they are processed, with a safety inspection to remove any lithium-ion batteries, which pose a risk due to their flammability.

Why is it important to separate lead and lithium-ion batteries during recycling?

-It's important to separate lead and lithium-ion batteries because lithium-ion batteries are highly flammable and could create dangerous conditions during the recycling process of lead batteries.

What happens to the lead and plastic components of the battery during recycling?

-Lead is separated from plastic in a water-filled separation tank, where lead sinks, and plastic floats. The lead is then smelted, refined, and reused in new batteries, while the plastic is cleaned, melted, and used for new battery cases.

How is the lead recycled and reused in the battery industry?

-Reclaimed lead is smelted, refined, and turned into alloys to be used in the manufacturing of new batteries. This process is highly efficient, allowing the recycling and reuse of lead indefinitely.

What happens to the plastic components from the recycled batteries?

-The reclaimed plastic from the batteries is cleaned and melted, then extruded into pellets that are used to create new battery cases through an injection molding process.

What happens to the acid collected from spent lead batteries?

-The acid is treated and purified for use in new energy storage devices. In most cases, it is chemically neutralized into sodium sulfate, which is then used in products like laundry detergents or glass refining.

How is the sodium sulfate produced from battery acid utilized?

-After neutralizing the battery acid, sodium sulfate is separated and can be sold for use in household products like laundry detergents or in the glass industry for refining.

How is the recycling process in lead battery manufacturing nearly waste-free?

-The recycling process is nearly waste-free as any unused or substandard materials, like defective battery cases, are recycled. Additionally, the individual components—lead, plastic, and acid—are all reused, contributing to a sustainable cycle.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

BEGINI TAHAPAN PROSES PEMBUATAN BESI DAN BAJA DI PABRIK MODERN

⚠️ ¡DESMONTO una BATERÍA de 100 kWh! ⚡ | ¿SON tan ECOLÓGICAS como nos VENDEN?

Why your phone battery gets worse over time - George Zaidan

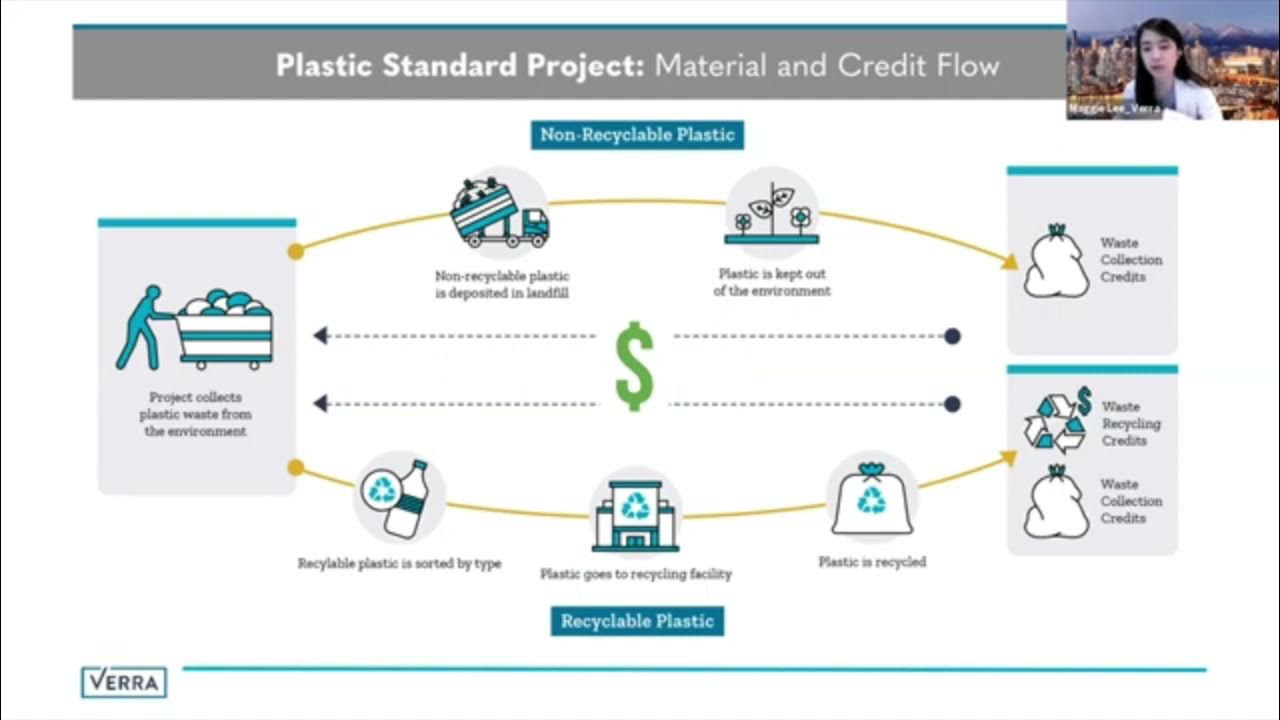

Plastic Standard Project by Verra

Pulp and Paper Making Process ( Proses Pembuatan Pulp dan Kertas )

"상당히 큰 파장 예상.." 이미 한국은 시작됐다

5.0 / 5 (0 votes)