TPST Bantargebang Manfaatkan Teknologi Refuse Derived Fuel (RDF)

Summary

TLDRThe video outlines a waste management project at Bantar Gebang, focusing on the processing of 1,000 tons of waste per day to produce RDF (Refuse-Derived Fuel). The process includes waste unloading, manual sorting, magnetic separation of metal, size reduction, drying, and further separation to produce RDF for use in the cement industry. The project also involves the construction of a landfill mining facility, truck washing stations, and power supply infrastructure. The goal is to reduce both new and existing waste volumes at the site, with the project expected to be completed by the end of 2023.

Takeaways

- 😀 The TPSD Bantargebang project aims to extend the service life of the waste processing facility and fill mining project.

- 😀 1,000 tons of waste per day will undergo a detailed processing flow at the facility.

- 😀 The first step involves waste being unloaded from the bunker with a retention period of 1-2 days.

- 😀 Afterward, the waste is manually sorted to remove large debris like rocks and glass.

- 😀 The waste then passes through a magnetic separator to remove ferrous metal materials.

- 😀 The waste is shredded to a uniform size under 12 cm by a primary shredder.

- 😀 Further sorting divides the waste into materials under 4 cm and organic waste.

- 😀 The waste is dried using solar energy and airflow from a blower, followed by mechanical drying at 350°C.

- 😀 A trommel screen further sorts the waste, separating materials above 4 cm in size.

- 😀 The refined waste then passes through an Eddy current separator to remove non-ferrous metals.

- 😀 The final output is Refuse-Derived Fuel (RDF), with a minimum of 350 tons produced per day, intended for use in the cement industry.

- 😀 The project also includes the development of a landfill mining facility, truck washing stations, workshops, and transformers to support the processing machines.

- 😀 The project is located on a 7.4-hectare site and is expected to be completed by the end of this year, with operations starting in January 2023.

Q & A

What is the main purpose of the project at the Bantar Gebang landfill?

-The main purpose of the project is to extend the operational period of the Bantar Gebang landfill by implementing a waste processing facility that converts waste into RDF (Refuse Derived Fuel) and develops a landfill mining system.

How much waste is processed daily in the Bantar Gebang project?

-The project processes approximately 1,000 tons of waste per day.

What is the first step in the waste processing procedure at the Bantar Gebang facility?

-The first step involves unloading the waste in the bunker, where it is allowed to stay for 1-2 days for retention.

What happens after the waste is moved from the bunker?

-After the waste is moved from the bunker, it is manually sorted to remove large objects such as stones and glass before passing through a magnetic separator to remove metal materials.

What is the function of the primary shredding machine in the processing process?

-The primary shredding machine is used to reduce the size of the waste to a uniform size, making it more manageable for further processing.

What is the maximum size of the material after the primary shredding process?

-After the primary shredding process, the size of the material is reduced to below 12 cm.

What happens to the waste after it is reduced to below 12 cm?

-The waste is then further sorted to separate organic waste and materials smaller than 4 cm, and it undergoes drying processes using sunlight and a mechanical dryer.

How does the drying process work at the Bantar Gebang facility?

-The waste is initially dried using sunlight and wind generated by blowers, followed by mechanical drying at a temperature of around 350°C in a kiln dryer.

What is the final output from the waste processing unit?

-The final output from the waste processing unit is RDF (Refuse Derived Fuel), with a minimum of 350 tons produced per day, which can be supplied to the cement industry.

What additional infrastructure is included in the project aside from the waste processing facility?

-The project also includes a truck washing station, a workshop, a guardhouse, and a transformer house to supply electricity to the machines used in the waste processing facility.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

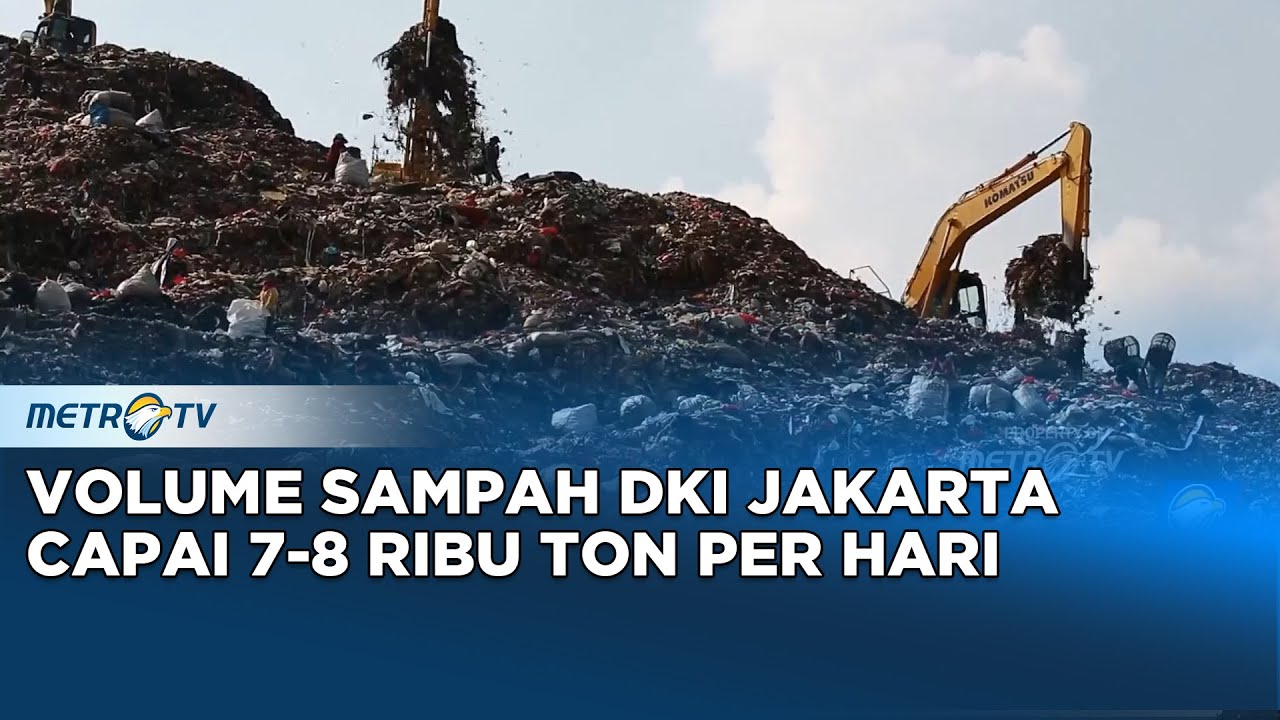

REALITAS - Bantar Gebang, Jantung Sampah Jakarta Bermuara

Pengolahan Sampah Dengan Teknologi RDF

Jutaan Sampah DKI Jakarta berkumpul disini - TPST Bantar Gebang

Pengelolaan Sampah Padat Perkotaan

Pengolahan Sampah Tandingan Banyumas Ada di JAKARTA! - Jangjo Indonesia

SIG Sulap 16 Ribu Ton Sampah Jadi Bahan Bakar

5.0 / 5 (0 votes)