Simulation of Multicomponent Rigorous Distillation in DWSIM

Summary

TLDRThis tutorial teaches users how to simulate a multi-component rigorous distillation column using the free open-source DW SIM software. The video covers the entire process, from setting up the feed stream with specific components to configuring and running the distillation column simulation. Key topics include selecting components, specifying pressure and temperature conditions, calculating reflux ratios, and analyzing important profiles like temperature, pressure, and component fractions. By the end, viewers will understand how to apply shortcut distillation methods and rigorous simulation techniques to optimize the separation of hydrocarbons in a distillation column.

Takeaways

- 😀 DW Sim is a free and open-source chemical process simulator used for multi-component rigorous distillation simulations.

- 😀 The tutorial focuses on simulating a distillation column, calculating the minimum reflux ratio, and analyzing column profiles such as temperature, flow rate, and component fraction.

- 😀 The problem involves a feed of alkanes at 2 bar pressure and 500 kmol/h flow rate, with specific mole fractions for components like propane, isobutane, isopentane, normal hexane, and normal heptane.

- 😀 The tutorial demonstrates the process of setting up a distillation column in DW Sim, including the selection of components, thermodynamic property package (Peng-Robinson), and unit system (C5).

- 😀 Key concepts like light key and heavy key components are explained, with isopentane as the light key and normal hexane as the heavy key.

- 😀 The reflux ratio is initially set at 1.5 times the minimum reflux ratio, and the distillate and bottom product pressures are specified at 1.8 bar and 2 bar, respectively.

- 😀 The script details how to set up feed stream properties, including pressure (2 bar), flow rate (5000 kg mol/h), and vapor fraction (0) for the saturated liquid feed.

- 😀 The shortcut distillation method is first applied to calculate the minimum reflux ratio, actual number of stages (14), and the optimum feed stage location (stage 7).

- 😀 Once the shortcut method is completed, the rigorous distillation column is set up in DW Sim, with inputs from the shortcut distillation results used for accurate column specifications.

- 😀 After running the simulation, the results show the condenser and reboiler duties, and the temperature, pressure, and component profiles for both liquid and vapor phases in the distillation column.

Q & A

What is the primary goal of this tutorial?

-The main goal of this tutorial is to teach how to simulate a multi-component rigorous distillation column using DW Sim software, which is a free and open-source chemical process simulator.

What are the key components involved in the distillation simulation?

-The key components involved in the distillation simulation are propane, isobutane, isopentane, normal hexane, and normal heptane, which make up the feed mixture.

What is the specified light key and heavy key component in the feed mixture?

-In the feed mixture, isopentane is specified as the light key component, and normal hexane is specified as the heavy key component.

What is the reflux ratio and how is it calculated?

-The reflux ratio in the simulation is 1.5 times the minimum reflux ratio. The minimum reflux ratio is calculated using the shortcut distillation method, and the actual reflux ratio is determined by multiplying the minimum value by 1.5.

What are the desired product specifications for the distillation process?

-The desired product specifications are that the light key component (isopentane) should not exceed 1 mole fraction in the bottoms, and the heavy key component (normal hexane) should not exceed 1 mole percent in the distillate.

What are the operating pressures for the distillation column?

-The feed enters the column at 2 bar pressure, the distillate (condenser) pressure is 1.8 bar, and the bottom product (reboiler) pressure is set to 2 bar.

What is the significance of the feed stage location in the distillation column simulation?

-The feed stage location determines where the feed enters the column. In this simulation, the optimum feed stage location is found to be at stage 7 based on the results of the shortcut distillation method.

How is the column pressure profile defined?

-The column pressure profile is estimated by interpolation in the DW Sim software, and this helps to adjust the pressures across the stages to avoid unrealistic pressure values like zero pressure in stages 11 and 12.

What results are obtained from running the shortcut distillation method?

-The results from the shortcut distillation method include the minimum reflux ratio, the actual reflux ratio, the number of stages (14), the optimum feed stage location (7), and the bottom and top product flow rates (27.55 and 22.49 kmol/hr, respectively).

What are the key features of the DW Sim software demonstrated in this tutorial?

-Key features of DW Sim demonstrated include the ability to simulate rigorous multi-component distillation columns, define pressure and temperature profiles, specify feed conditions, and calculate important results like reflux ratios, stage locations, and flow rates, all within an open-source platform.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Free Download and Installation of DWSIM | Shortcut Distillation Calculations in DWSIM

CADe SIMU AULA 1

Tutorial Ventoy : Membuat multi bootable USB Flashdisk. Banyak OS dalam satu Flashdik. Mantap...!!!

Sistem Operasi atau OS itu apa sih? Penting nggak? Apa aja contohnya? Jenisnya ada berapa?

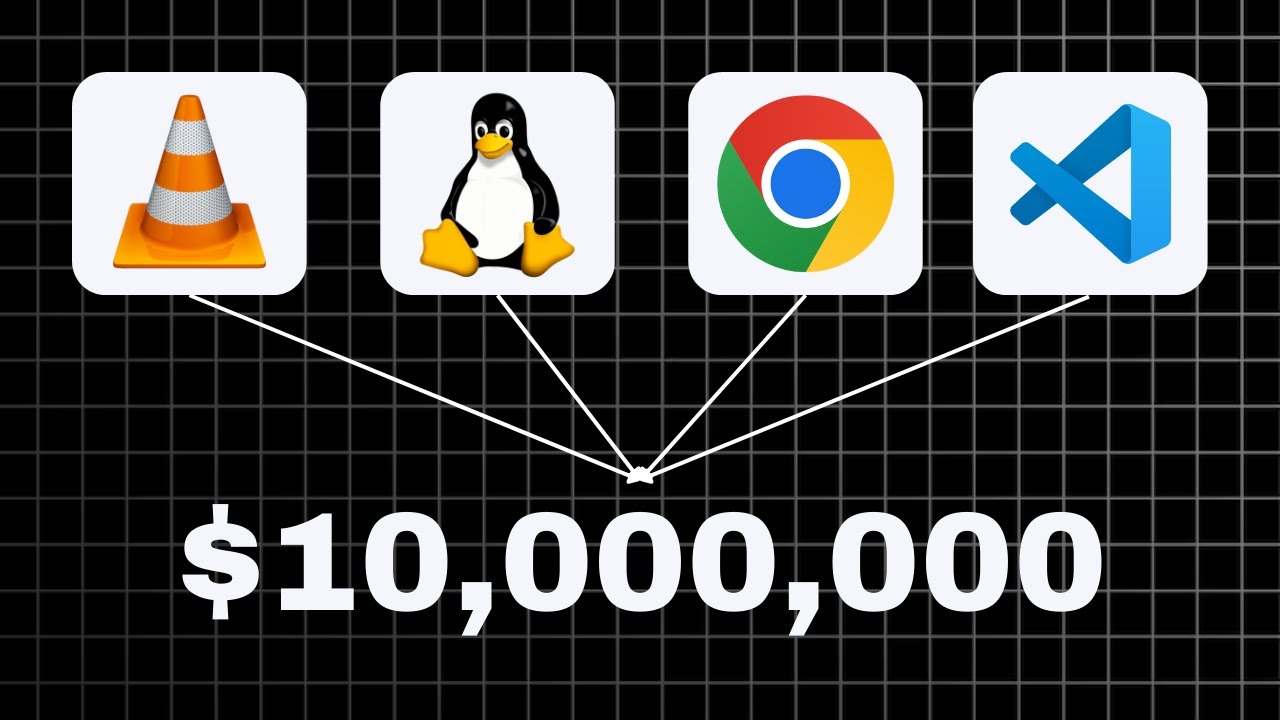

How Free Software Actually Make Money

Tutorial de Freecad (1/40): Presentación

5.0 / 5 (0 votes)