Telecurso 2000 - Processos de Fabricação - 41 Fresagem

Summary

TLDRIn this educational video on milling processes, viewers learn about the different types of milling machines, such as horizontal, vertical, and universal models, and the tools used in milling, particularly various types of milling cutters (fresas). The video explains the principles of material removal during milling, focusing on factors like tool movement and the impact of machine settings on finish quality. It also covers the selection of appropriate tools based on the material being machined. The content delves into milling operations, machine classifications, and practical applications, providing a comprehensive understanding of milling technology for beginners.

Takeaways

- 😀 The milling process, called 'fresagem,' allows the removal of material from a piece using a milling machine and special tools called 'fresas'.

- 😀 Milling can handle various surface types, including flat, convex, concave, and special profiles.

- 😀 A milling machine operates by combining two movements: the rotation of the tool (fresa) and the movement of the table that holds the workpiece.

- 😀 The movement of the table can be 'concordant' (same direction as the tool) or 'discordant' (opposite direction), impacting the finish quality.

- 😀 Milling machines are categorized based on the orientation of their spindle (tree), with types being horizontal, vertical, and universal (both horizontal and vertical).

- 😀 Special milling machines include the copying mill, which duplicates a model, and the pantograph mill, which is manually coordinated for detailed work.

- 😀 Milling tools (fresas) have multiple cutting edges or teeth, and the correct selection depends on the material being machined and the operation's nature.

- 😀 The hardness of the material influences the choice of fresa, with 'W' types used for softer materials and 'H' types for harder, more brittle materials.

- 😀 Different types of fresas include flat, constant profile, angular, and slotting tools, each designed for specific types of machining.

- 😀 The fresa's life span is affected by wear, so maintaining it, especially through cooling and appropriate tool selection, is critical for efficient operation.

Q & A

What is milling, and how is it performed?

-Milling is a mechanical machining process used to remove excess material from a workpiece, shaping it to desired dimensions and forms. This is done using a milling machine with tools called 'cutters' or 'mills'. The material is removed through a combination of two movements: the rotation of the cutter and the movement of the workpiece across the tool.

What are the main movements involved in the milling process?

-The main movements in milling are the rotation of the cutter (the milling tool) and the movement of the workpiece on the machine's table. The workpiece can be advanced towards the rotating cutter in either a 'concurrent' or 'countercurrent' direction.

What is the difference between 'concurrent' and 'countercurrent' milling?

-In concurrent milling, the workpiece moves in the same direction as the rotation of the cutter, which can cause irregular movements and potential damage to the tool due to play in the machine components. In countercurrent milling, the workpiece moves against the cutter's rotation, ensuring smoother, more controlled movement and better finish quality.

How are milling machines classified?

-Milling machines are classified based on the orientation of the spindle relative to the table. The three main types are horizontal mills (where the spindle is parallel to the table), vertical mills (where the spindle is perpendicular to the table), and universal mills (which have both horizontal and vertical spindles for more flexibility in machining).

What is the function of a copy milling machine?

-A copy milling machine is designed to replicate a specific model or pattern onto a workpiece. This type of milling machine can copy a design precisely, often used in mass production of identical parts.

How does a pantograph milling machine work?

-A pantograph milling machine is manually controlled by an operator, allowing for the copying of designs with high precision. It is typically used for intricate details such as small channels or radii. The operator's skill and the tool's configuration determine the level of detail that can be achieved.

What are the differences between W, N, and H type milling cutters?

-The W type milling cutter has a smaller cutting angle and is used for machining softer materials like aluminum, bronze, and plastic. The N type cutter has a medium angle and is suitable for machining medium-hard materials like mild steel. The H type cutter has the largest cutting angle, making it ideal for hard materials such as high-carbon steel or brittle materials.

Why are some milling cutters designed with more teeth than others?

-Milling cutters with more teeth are typically used for softer materials that can allow for more cutting points. For harder materials, cutters with fewer teeth are preferred because they produce smaller chips and require less power per tooth, which improves tool life and efficiency.

What are the different types of milling cutters, and what are their uses?

-There are various types of milling cutters, each suited for different applications. For example, flat cutters are used for creating flat surfaces or grooves; angular cutters are used for cutting at specific angles or profiles; keyway cutters are used for creating keyways; and cutter heads with replaceable inserts are used for high-volume operations. Additionally, roughing cutters are used for removing large volumes of material quickly.

How do you choose the correct milling cutter for a given task?

-The choice of milling cutter depends on several factors, including the material being machined, the type of cut to be made, and the desired finish. For instance, softer materials like aluminum require a cutter with fewer teeth, while harder materials like steel need cutters with more robust designs and higher cutting angles.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Bagian-bagian Utama Mesin Frais konvensional

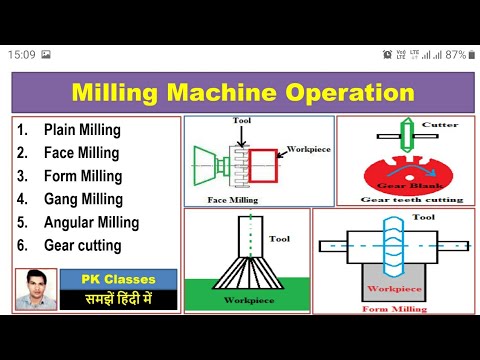

Milling Machine Operations (हिन्दी)

XI TPM - Teknik Pemesinan Frais - Memahami Bagian Bagian Mesin Frais Berdasarkan Jenis & Fungsinya

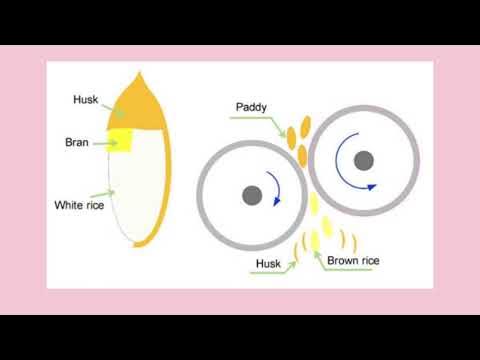

How Rice is Milled: Exploring the Rice Milling Process from Harvesting to Packaging (Flowchart)

Tutorial Mesin frais bagi pemula

Milling machine tutorial - cutter selection, speeds and feeds, coolant, high speed machining

5.0 / 5 (0 votes)