Milling Machine Operations (हिन्दी)

Summary

TLDRThis video provides an in-depth overview of milling machine operations, covering various techniques used in metalworking. Key operations such as plain milling, face milling, form milling, gang milling, angular milling, and gear cutting are explained in detail. The video highlights the use of multi-point cutting tools, the importance of precise feed rates, and how different tools are employed to achieve specific outcomes. It also discusses the process of indexing for gear cutting and how gang milling improves efficiency. The explanation offers a comprehensive understanding of milling machines' versatile role in manufacturing.

Takeaways

- 😀 Milling machines are used for various operations to manufacture workpieces as per specific requirements.

- 😀 Milling involves metal removal by feeding a workpiece against a rotating multi-point cutting tool mounted on the machine's table.

- 😀 Multi-point cutting tools have multiple cutting teeth and are commonly used in milling operations for efficient material removal.

- 😀 Plain milling creates flat surfaces parallel to the cutter’s axis, removing material in layers from the workpiece.

- 😀 Face milling is used to machine the face of a workpiece, creating flat surfaces with right angles.

- 😀 Form milling is used to produce complex shapes or contours on the workpiece using a specially designed cutter.

- 😀 Gang milling involves using multiple cutting tools simultaneously to perform different operations on the workpiece.

- 😀 Angular milling generates angular surfaces on a workpiece by machining at specific angles.

- 😀 Gear cutting is done on a milling machine to produce teeth on a gear blank, with indexing used to divide the workpiece into equal parts.

- 😀 Indexing involves dividing the gear blank into equal parts and performing cuts sequentially to generate gear teeth with precision.

Q & A

What is a milling machine?

-A milling machine is a metal-removing process where a workpiece is fed against a rotating multi-point cutting tool. The cutting tool rotates along its axis, and the workpiece is moved via a table feed to remove material from it.

What are multi-point cutting tools?

-Multi-point cutting tools have more than one cutting edge or tooth. In milling machines, these tools remove material by having multiple cutting points, as opposed to single-point tools like drills.

What types of operations can be performed on a milling machine?

-Operations such as plane milling, face milling, angular milling, form milling, gang milling, and gear cutting can be performed on a milling machine.

What is plane milling?

-Plane milling, also known as slab milling, involves creating a flat surface on the workpiece. The cutting tool operates parallel to the surface, removing material in layers.

How does face milling work?

-In face milling, the cutting tool works on the face of the workpiece to produce a flat surface. The tool has teeth on the periphery and face, removing material from the workpiece in small layers.

What is form milling and when is it used?

-Form milling is used to create specific shapes or contours on a workpiece. The cutting tool has a specialized shape that matches the desired form, and it operates on the workpiece to create these shapes.

What is gang milling?

-Gang milling involves using multiple cutting tools simultaneously on the workpiece. Several tools are mounted together and work at once to speed up the machining process.

What does angular milling involve?

-Angular milling involves cutting surfaces at angles other than 90 degrees. In this operation, the cutting tool is positioned at an angle to the workpiece, producing an angular surface.

What is gear cutting in milling machines?

-Gear cutting involves creating gears on a workpiece. The process uses an indexing feature to divide the gear blank into equal parts, with the cutter removing material to form teeth on the gear.

What is indexing in milling machines?

-Indexing in milling machines is the process of dividing a circular gear blank into equal parts for cutting teeth. This is achieved by rotating the gear blank to specific positions after each cut, ensuring that the teeth are evenly spaced.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

All Lathe Machine Operations: Turning, Facing, Taper Turning, Boring, Knurling, Tapping, Forming

Telecurso 2000 - Processos de Fabricação - 41 Fresagem

Bagian-bagian Utama Mesin Frais konvensional

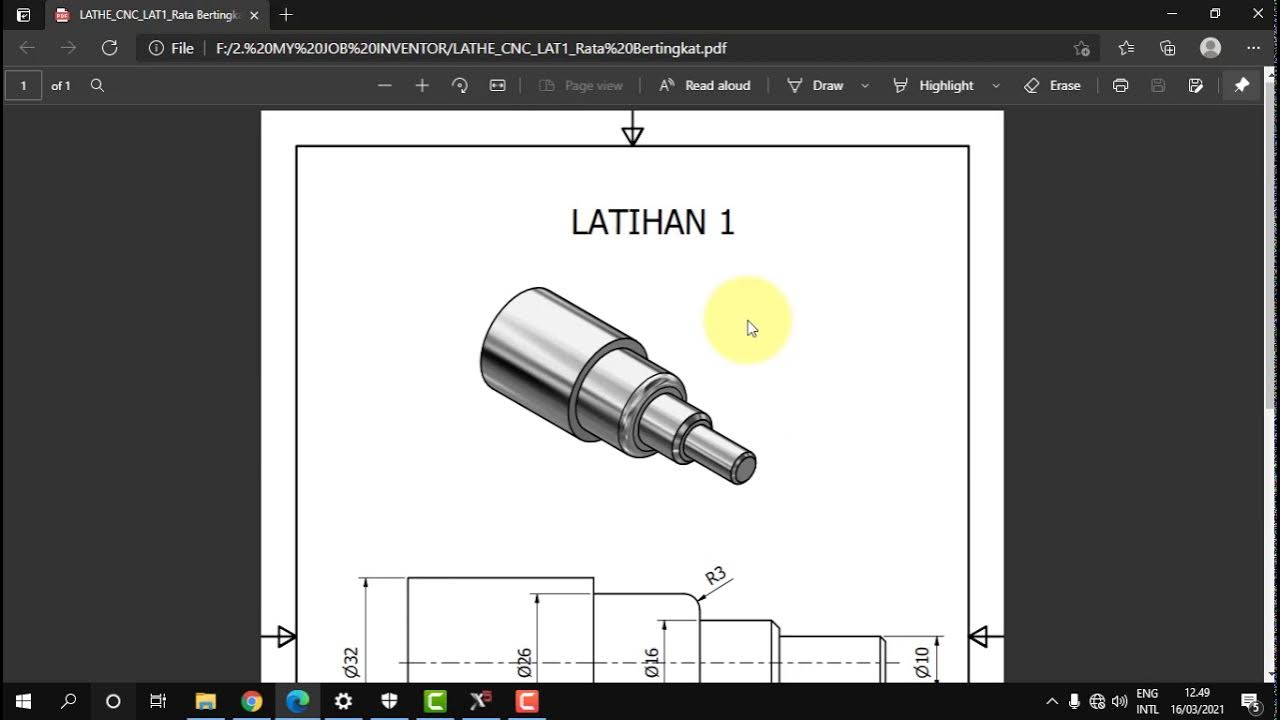

Latihan Soal Teknik Mesin/Pemesinan #mesin bubut

XI TPM - Teknik Pemesinan Frais - Memahami Bagian Bagian Mesin Frais Berdasarkan Jenis & Fungsinya

MASTERCAM X5_BUBUT DASAR BIDANG BERTINGKAT

5.0 / 5 (0 votes)