Mushroom® Packaging

Summary

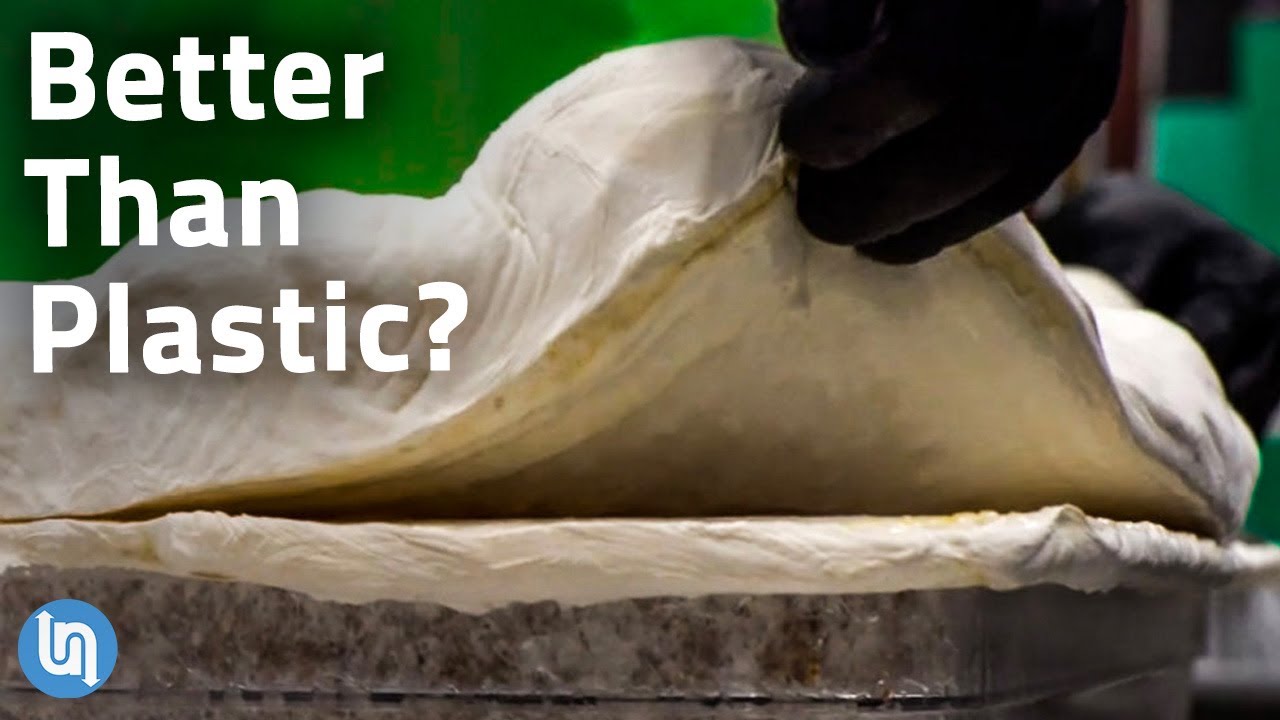

TLDRMushroom packaging is an innovative, eco-friendly alternative to traditional petrochemical-based foams, offering a sustainable solution to reduce plastic waste. Made from agricultural byproducts and mycelium, it forms a biocomposite that can be custom-molded for various products. This home and industrial compostable packaging is safe, allergen-free, and enhances soil nutrition. Ecovative's team continuously improves this high-performing, cost-competitive packaging, encouraging a global shift away from wasteful plastics.

Takeaways

- 🌱 Mushroom packaging is a compostable alternative to synthetic foams like polystyrene, polyethylene, and polypropylene, which are contaminating the Earth.

- 🌾 It is made from agricultural byproducts and the root structure of mushrooms, known as mycelium, with no petrochemicals or plastics required.

- 🏭 The production process combines advanced automation with indoor farming techniques to create a biocomposite material.

- 🛍️ This biocomposite material can be custom molded into any shape to protect products and is then heat treated to stop growth and ensure safety.

- 🌳 Mushroom packaging is safe for home composting or industrial composting facilities, enriching the soil with natural materials.

- 🔄 It does not biodegrade in use, ensuring that it serves its purpose as protective packaging before being composted.

- 🛠️ Ecovative Design's team of experts, including engineers and biologists, is continuously innovating to improve the performance of mushroom packaging.

- 🌐 The unique production system is a turnkey solution for companies looking to switch to sustainable packaging options.

- 💰 Mushroom packaging is cost-competitive, offering a high-performing and sustainable alternative to plastic foams.

- 🌐 It is used globally to protect a variety of products, from sensitive electronics to heavy furniture.

- 💡 The packaging leaves a positive first impression on customers, showcasing a company's commitment to sustainability.

Q & A

What is mushroom packaging?

-Mushroom packaging is a home compostable alternative to synthetic foams such as expanded polystyrene, polyethylene, and polypropylene. It is made from agricultural byproducts and the root structure of mushrooms, known as mycelium, without the use of petrochemicals or plastics.

Why is mushroom packaging considered a sustainable alternative to traditional foams?

-Mushroom packaging is sustainable because it is made from renewable resources like mycelium and agricultural waste, which are biodegradable and compostable, reducing the environmental impact compared to petrochemical-based foams.

What are the main inputs used in making mushroom packaging?

-The main inputs used in making mushroom packaging are agricultural byproducts such as corn stalks and the mycelium, the root structure of mushrooms.

How is the biocomposite in mushroom packaging formed?

-The biocomposite in mushroom packaging is formed by binding together mycelium and agricultural waste to create a material that can be custom molded into any shape to protect products.

What is unique about the factories that produce mushroom packaging?

-The factories that produce mushroom packaging combine advanced automation with specialized indoor farming techniques to grow and process the packaging material.

How long does it take to grow packaging parts in mushroom packaging production?

-Growing packaging parts in mushroom packaging production only takes a couple of days.

What process is used to stop the growth of the packaging parts after they are formed?

-After the packaging parts are grown, they undergo a heat treatment process to stop the growth and ensure no spores or allergens are produced.

What types of products can be protected using mushroom packaging?

-Mushroom packaging can be used to protect a variety of products, including sensitive electronics and heavy furniture.

How can customers dispose of mushroom packaging after use?

-Customers can compost mushroom packaging at home or at industrial composting facilities, where the natural materials will decompose and add nutrients to the soil.

What benefits does mushroom packaging offer to companies looking to eliminate wasteful plastic foams?

-Mushroom packaging offers high performance, cost competitiveness, and a positive first impression on customers, while also being environmentally friendly and helping companies reduce their reliance on plastic foams.

How does Ecovative's team contribute to the innovation of mushroom packaging?

-Ecovative's team of engineers, biologists, material scientists, packaging designers, and production experts continuously innovate to improve the performance of mushroom packaging and develop unique production systems.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

The Earth Prize 2025 North America Winner: StuyBigCompGroup!

This piece of paper could revolutionize human waste

KBMK 2024 - PING PING - UISI - Bidang Perencanaan Keuangan dan Bisnis - Juara Terbaik Nasional 1

Is Mycelium Fungus the Plastic of the Future?

Banana Peels From Waste To wealth: Creating Bioplastic and Eco Friendly Paper For a Greener Future.

10 Sustainable Food Packaging Companies To Support

5.0 / 5 (0 votes)