Material Teknik Minggu XII Keramik 2

Summary

TLDRThis lecture delves into the mechanical properties, classification, and applications of ceramics, highlighting their brittleness and inability to deform plastically under stress. It covers how ceramics are tested, especially through bending tests, due to their tendency to fracture quickly. The lecture also explores various applications, including glass, structural ceramics, refractories, abrasives, and advanced ceramics used in industries like electronics. The importance of properties such as hardness and porosity in ceramic materials is also discussed, alongside their production and fabrication techniques, preparing students for real-world engineering challenges with ceramic materials.

Takeaways

- 😀 Ceramics are characterized by high hardness and brittleness, making them prone to fracture rather than plastic deformation under stress.

- 😀 Unlike metals, ceramics fail almost immediately under tensile stress without undergoing plastic deformation, which makes them more difficult to test for stress-strain behavior.

- 😀 The mechanical testing of ceramics often uses bending tests instead of tensile tests, as they don't exhibit elongation or plasticity.

- 😀 Ceramics, especially crystalline ones, have limited dislocation movement due to strong ionic or covalent bonds, which further contributes to their brittleness.

- 😀 Ceramics are commonly categorized based on their structure (e.g., silicates, carbon-based) and their application (e.g., glass, refractories, abrasives).

- 😀 Glass is a major category of ceramics, which can be formed from clay by heating at high temperatures and is widely used in structural and decorative applications.

- 😀 Refractory ceramics are designed to withstand very high temperatures without melting, and they are used in industrial applications like furnaces and kilns.

- 😀 Abrasive ceramics, like silicon carbide and aluminum oxide, are widely used for grinding, cutting, and polishing hard materials.

- 😀 Cement-based ceramics are used in construction for binding and hardening purposes when mixed with water and undergo a chemical setting process.

- 😀 Advanced ceramics, which are often used in high-tech industries like electronics and communications, are designed for precision and high performance under extreme conditions.

- 😀 The fabrication of ceramics involves processes like pressing, blowing, and forming, where temperature and viscosity play key roles in shaping the material.

Q & A

What was covered in the previous lecture on ceramics?

-In the previous lecture, the structure, classification, and chemical bonding of ceramics were discussed. The key focus was on their ionic bonds and their mechanical properties, including their behavior under stress, as well as a discussion of ceramic phase diagrams.

What are the main mechanical properties of ceramics?

-Ceramics are known for their brittleness and high hardness. They fracture under stress without undergoing plastic deformation, unlike metals which can deform plastically before breaking.

Why is it difficult to measure the stress-strain behavior of ceramics?

-Ceramics are highly brittle, meaning they fail almost immediately under stress, showing no significant plastic deformation. This makes it challenging to measure the stress-strain curve as seen in metals like iron or aluminum.

How is the mechanical testing of ceramics typically conducted?

-Ceramics are usually tested using bending tests, rather than tensile tests. Bending tests help measure the stress at different points of the ceramic specimen as it deforms under load.

What is the significance of the fracture behavior of ceramics?

-Ceramics fracture almost immediately when subjected to tensile stress, making them unsuitable for applications where plastic deformation is needed. This behavior is crucial in understanding how ceramics fail under different loading conditions.

How do dislocations affect the mechanical properties of ceramics?

-Dislocations are less likely to occur in ceramics because of their ionic or covalent bonding. This makes ceramics resistant to plastic deformation, contributing to their brittleness.

What are the applications of ceramics in different industries?

-Ceramics are used in a variety of industries, including construction (bricks, tiles), electronics (insulators), and in high-temperature applications (refractories). They are also essential in producing abrasives, semiconductors, and advanced ceramics for precision applications.

What are the different types of ceramics based on their applications?

-Ceramics can be categorized into six main types based on their applications: glass, clay products, refractories, abrasives, cement, and advanced ceramics.

What role does porosity play in the performance of refractory ceramics?

-The porosity in refractory ceramics affects their thermal insulation properties and strength. Optimal porosity is necessary to ensure good thermal insulation while maintaining sufficient mechanical strength.

How is glass made, and what is its key characteristic?

-Glass is made by heating a mixture of materials to a high temperature, causing them to melt and form a non-crystalline structure. Its key characteristic is its ability to be shaped when heated and its resistance to thermal shock due to its high viscosity at certain temperatures.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Kuliah 2 IBK Sifat Mekanis Bahan part 1

Mechanical Properties of Materials.

Bonding in Ceramics: Understand the Physical & Chemical Properties of Ceramics | #EME230

Material Teknik Keramik Kuliah ke12 Online

Stress and Strain Curve - Hooke's Law | Elasticity and Plasticity

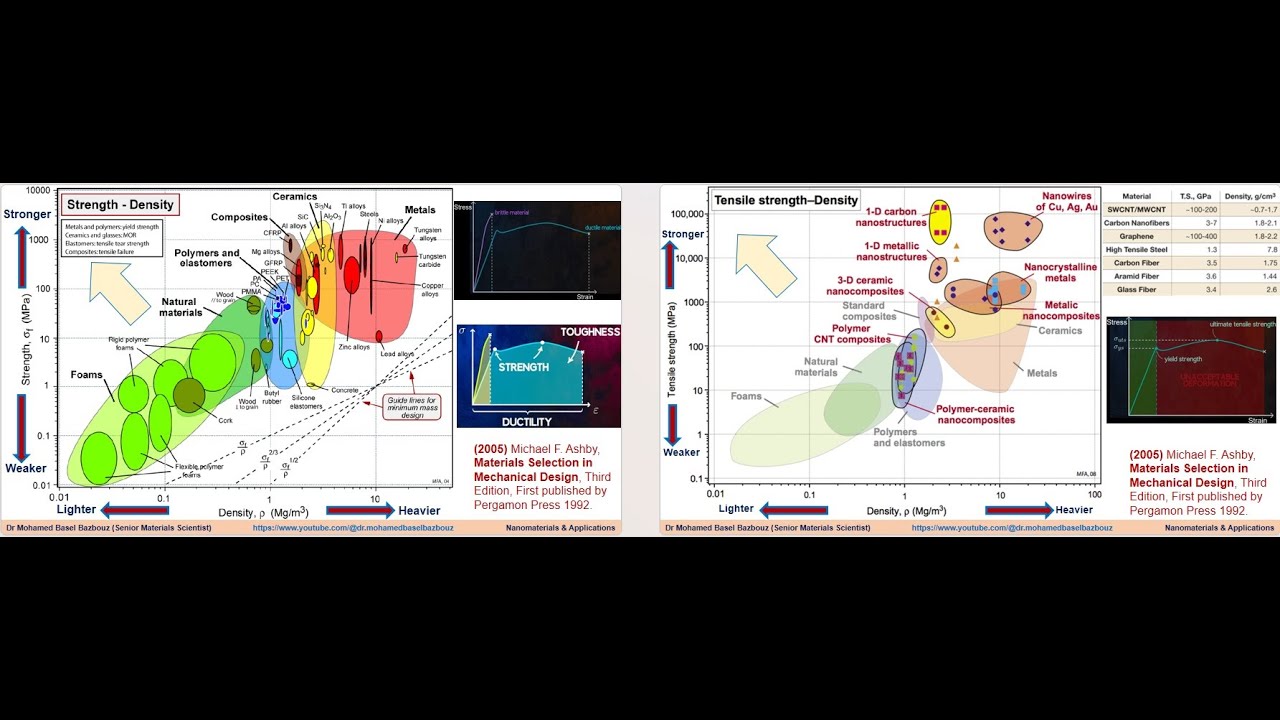

Ashby plots of Strength versus density for materials and nanomaterials المتانة والوزن النوعي

5.0 / 5 (0 votes)