Belajar Tentang Quality Control Adalah

Summary

TLDRThis video script explains the importance of proper quality control in business to ensure that products meet high standards before reaching customers. The speaker emphasizes three key aspects of quality control: incoming quality checks for raw materials, process checks during production, and finishing checks on final products. By adhering to these practices, businesses can prevent defects, reduce waste, and avoid customer complaints, which could damage the brand's reputation. The video encourages viewers to implement these quality control steps to maintain product excellence and customer satisfaction.

Takeaways

- 😀 Quality control is essential to ensure products meet the required standards and avoid customer complaints.

- 😀 Defects and rework can lead to waste and harm the brand's reputation.

- 😀 The three main steps in quality control are: incoming material check, process inspection, and finishing inspection.

- 😀 Incoming quality control involves checking raw materials upon arrival to ensure they meet specifications.

- 😀 Process quality control ensures that production processes are monitored and that any issues are addressed before moving to the next stage.

- 😀 Finishing quality control is the final inspection before products are delivered to customers, ensuring they meet the required standards.

- 😀 Defective materials, such as incorrect size or quality, should be rejected to avoid impacting the final product.

- 😀 For example, in construction, if steel bars are less than the specified 10mm, they should be rejected.

- 😀 Process quality control might involve inspecting surfaces or finishes, like ensuring walls are smooth before painting.

- 😀 Effective quality control helps in maintaining product quality, customer satisfaction, and reduces complaints.

- 😀 Following proper quality control processes can increase customer loyalty and reduce business waste.

Q & A

Why is quality control important in business?

-Quality control is crucial because it ensures that all products produced meet the required standards. Without proper quality control, defective or substandard products could reach customers, leading to complaints, damage to the brand's image, and potential waste in the form of rework or production failure.

What are the three main types of quality control processes?

-The three main types of quality control are: 1) Incoming Quality Control (IQC), 2) Process Quality Control (PQC), and 3) Finishing Quality Control (FQC). Each step ensures that materials, production processes, and finished products meet the required standards.

What is Incoming Quality Control (IQC)?

-Incoming Quality Control involves checking all materials received in the warehouse to ensure they meet the specified standards. For example, if a material like steel is ordered to a specific size (e.g., 10 mm), the incoming control checks to ensure that it matches the required dimensions.

How does Process Quality Control (PQC) work?

-Process Quality Control ensures that products are monitored during the production process. If issues arise, such as uneven or rough surfaces in wall finishing, the process is halted until corrections are made. This prevents defects from moving forward in the production cycle.

What is the role of Finishing Quality Control (FQC)?

-Finishing Quality Control is the final check before a product is shipped to the customer. It ensures that the final product meets the necessary standards and prevents any customer complaints regarding product quality.

What is the consequence of failing to implement quality control?

-Without quality control, businesses risk producing defective products, which can lead to customer dissatisfaction, returns, complaints, and ultimately damage the business's reputation and brand.

Why is it important to perform quality checks on materials before they are used in production?

-Checking materials before production helps ensure that only high-quality, defect-free components are used in manufacturing. This prevents delays, waste, and defects in the final product, thereby saving costs in the long term.

How does poor quality control affect the overall business?

-Poor quality control leads to higher costs due to the need for rework, refunds, or returns. It can also result in customer dissatisfaction, loss of brand trust, and possible long-term negative effects on sales.

What happens if quality issues are found during the production process?

-If quality issues are found during production, the process is halted until corrections are made. This ensures that no defective products continue through the production line, preventing further complications down the road.

How can businesses prevent quality problems in the first place?

-Businesses can prevent quality problems by implementing robust quality control at every stage—starting from incoming material checks, continuing through the production process, and ending with final inspections. Regular training, monitoring, and feedback loops are also essential to maintaining high standards.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Perbedaan Quality Control dan Quality Assurance di Industri Pangan

Metode Pengendalian Mutu atau Quality Control

Inspection and Quality control in Manufacturing. What is quality inspection?

Understanding Quality Control, Quality Assurance, And Food Safety in The Food Industry

Why The Chinese Products Are Low Quality? | Ask Siri

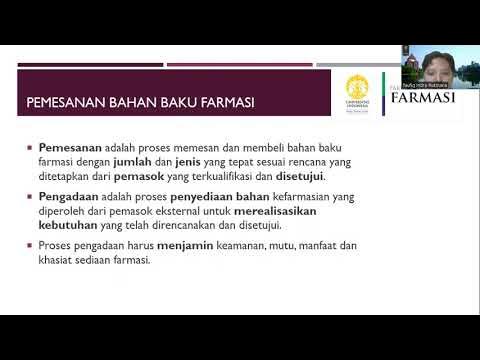

MOOCs Pengelolaan Bahan Baku dan Produk di Industri Farmasi (Sesi 1)

5.0 / 5 (0 votes)