Mengelas Pelat Posisi di Bawah Tangan(1F, 1G) dengan Proses Las GMAW - Teknik Pengelasan

Summary

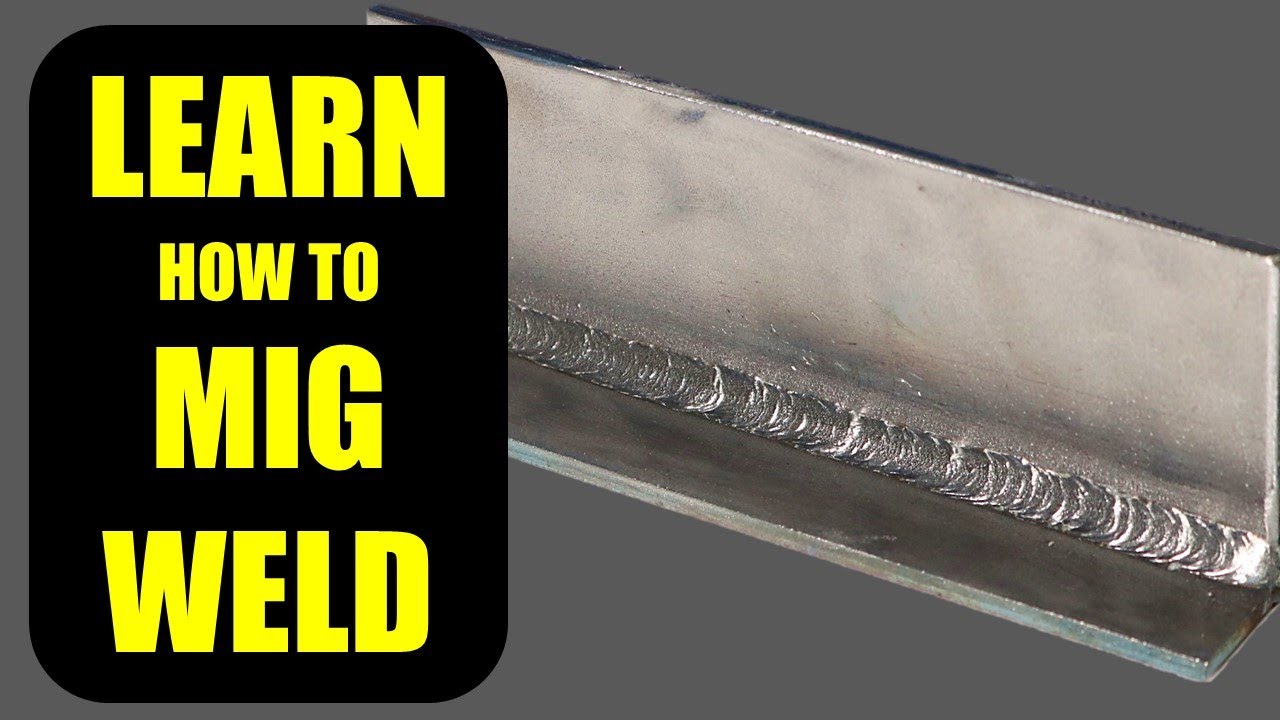

TLDRThis instructional video by Tony, a welding teacher at SMKN 1 Singosari in Malang, focuses on teaching welding techniques using the BMW welding machine. It covers preparation steps, including setting the workpiece, adjusting machine settings, and understanding electrode classifications. The video details two welding positions—fillet and groove—and outlines essential procedures like controlling welding voltage and amperage. The instructor emphasizes safety, proper storage of welding materials, and identifies common defects like undercut or porosity. The video concludes with post-welding checks and maintenance tips for optimal results.

Takeaways

- 😀 Introduction of the video and speaker Tony, a teacher at SMKN 1 Singosari, Malang.

- 😀 The focus of the tutorial is on welding, specifically with flat positions and Sasuke using BMW machines.

- 😀 The lesson begins with enthusiasm, emphasizing starting with energy and ending with success.

- 😀 Procedure for setting up the workpiece with current set to 100-120 amperes for welding with carbon steel.

- 😀 The workpieces will be arranged in a 'P' shape with a 90° angle, preparing for welding with 1G groove position.

- 😀 Specification of the workpiece: carbon steel, 150mm in width, 300mm in length, 10mm thick, with a 30° tilt angle.

- 😀 Explanation of root gap of 2-3mm and the preparation of the welding machine, including gas and electrode setup.

- 😀 Step-by-step guide on setting up the welding machine, including adjusting gas pressure and flowmeter, and selecting electrode type.

- 😀 Discussion of electrode classifications, focusing on the strength and composition of the materials used in the welding process.

- 😀 The welding process in GMAW involves three phases: root layer, filler layer, and cap layer, which must be checked for defects like undercut, porosity, and incomplete fusion.

- 😀 Instructions on how to properly store and maintain welding wires and electrodes to prevent contamination and ensure good results, including temperature control and humidity management.

Q & A

What is the purpose of the training session mentioned in the transcript?

-The training session is focused on welding techniques, specifically discussing how to weld using a carbon steel plate in various positions with a BMW welding machine.

What are the key components of the setup for the welding process?

-The setup includes the welding machine, carbon steel plates, a gas regulator, CO2 gas for shielding, and the appropriate welding electrodes.

What is the significance of the 1F position in welding?

-The 1F position refers to a flat welding position where the welding is performed horizontally on the plate. It is one of the basic welding positions for creating a fillet weld.

What is the recommended current setting for the welding process?

-The recommended current for the welding process is between 100 and 120 amperes.

How should the welding electrode be classified?

-The welding electrode should be classified with a code that includes the electrode type, root symbol, minimum tensile strength, and the material composition, such as carbon steel.

What is the significance of the root gap in the welding process?

-The root gap is the space between the edges of the welded materials and plays a crucial role in ensuring proper fusion during welding. It should be between 2 and 3 mm, according to the standards.

What should be done before starting the welding process?

-Before starting, the welder should set up the equipment, including checking the gas pressure, adjusting the machine settings, and confirming the amperage and voltage.

What is the process for checking the quality of a weld after completion?

-The weld should be visually inspected, including checking the fit-up and reinforcement, ensuring there are no defects such as undercut or porosity, and measuring angles to ensure the correct weld alignment.

What common defects are to be checked for after welding?

-Common defects to check for include undercut, porosity, overlap, incomplete fusion, and lack of proper reinforcement.

How should welding materials be stored to maintain quality?

-Welding materials, especially electrodes, should be stored in a dry place, away from moisture. Certain electrodes, like hydrogen-basic types, should be stored in an oven at specific temperatures to prevent moisture absorption.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

belajar las Tig/Argon pada media besi||teknik dasar

SMAW multi pass fillet welds T joints, flat Horizontal Vertical and Overhead Positions E7018

STICK WELDING 101: Getting Started With SMAW

How to MIG Weld for Beginners: MIG Welding Basics

Stick Welding Basics: Full Tutorial

Step by Step: How to Setup a Stick Welder

5.0 / 5 (0 votes)