Cylinder Bore Gauge: Komponen, Fungsi dan Cara Menggunakan

Summary

TLDRThis video tutorial guides viewers through the process of using a cylinder bore gauge to measure the diameter of an engine. It covers the components of the gauge, including the dial gauge, grip, and replacement roads. The tutorial also demonstrates how to set up the tool, calibrate a micrometer, and measure the cylinder diameter accurately. The presenter uses a Toyota 4K engine as an example, explaining the process step-by-step and showing how to measure wear on the cylinder. Viewers are encouraged to leave comments or questions about using the gauge.

Takeaways

- 😀 A cylinder bore gauge is a precise measuring tool used to measure the diameter of cylinders and other components.

- 😀 The cylinder bore gauge consists of a dial gauge and a measuring point that moves freely to show the measurement on the dial.

- 😀 The measurement point and replacement road are equivalent to the diameter of the object being measured.

- 😀 Components of the cylinder bore gauge include the dial gauge, grip, replacement road, replacement washer (with various thicknesses), and securing thread.

- 😀 The procedure begins with measuring the diameter of the cylinder with a caliper to ensure accurate setup before using the bore gauge.

- 😀 The standard diameter for a Toyota 4K engine is between 75.00 mm and 75.03 mm, which is referenced for comparison during measurement.

- 😀 The dial gauge is installed on the grip and calibrated by rotating it until the needle points to 1 on the scale before securing it in place.

- 😀 The replacement road is installed into the grip to secure the gauge for accurate readings during measurement.

- 😀 A micrometer, calibrated within the range of 75 mm to 100 mm, is used to further verify the measurements of the cylinder's diameter before using the bore gauge.

- 😀 The final measurement using the cylinder bore gauge indicates that the cylinder's diameter is 75.03 mm, accounting for wear over time and use.

Q & A

What is the purpose of a cylinder bore gauge?

-A cylinder bore gauge is used to measure the diameter of cylinders and other components accurately, particularly for assessing wear and tear over time.

How does the measuring point of a cylinder bore gauge work?

-The measuring point in a cylinder bore gauge moves freely and the amount of movement is displayed on the dial gauge, which shows the diameter of the object being measured.

What are the main components of a cylinder bore gauge?

-The main components of a cylinder bore gauge include the dial gauge, grip, replacement road, replacement washer, and securing thread.

What are the specifications of the standard diameter for the Toyota 4K engine?

-The standard diameter for the Toyota 4K engine is between 75.00 mm and 75.03 mm.

What is the role of the Vernier caliper in measuring the diameter before using the cylinder bore gauge?

-The Vernier caliper is used to measure the internal diameter of the cylinder before using the cylinder bore gauge, to ensure that the diameter is around 75 mm, but the exact measurement is unknown until further tools are used.

What is the purpose of using a micrometer after the Vernier caliper?

-The micrometer is used to get a more precise measurement of the cylinder diameter, ensuring it falls within the specified range of 75 mm to 100 mm.

How is the micrometer calibrated before use?

-The micrometer should be calibrated before use to ensure accurate measurements. The script suggests watching a separate video on how to calibrate a micrometer.

Why is it important to position the replacement road in the middle of the spindle when using the micrometer?

-Positioning the replacement road in the center of the spindle ensures accurate measurement by keeping the micrometer properly aligned, which prevents errors in the reading.

What does the movement of the dial gauge needle indicate during the measurement?

-The movement of the dial gauge needle indicates the amount of wear or deviation in the cylinder's diameter. A maximum movement of the needle shows the extent of the wear.

How is the final measurement of the cylinder diameter determined?

-The final diameter measurement is determined by adding the wear value (e.g., 0.03 mm) to the standard value. For example, if the original diameter is 75 mm and the wear is 0.03 mm, the final diameter would be 75.03 mm.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

CYLINDER BORE GAUGE ' CARA MENGGUNAKAN, MEMBACA, DAN MENGUKUR DIAMETER SILINDER

Pengukuran | Jangka Sorong | IPA Kelas 7 SMP/MTs | EDURAYA MENGAJAR

How To Set Valve Lash On A 6.6 Duramax Diesel Engine

Cylinder Head Warpage Check - How to Measure Warpage

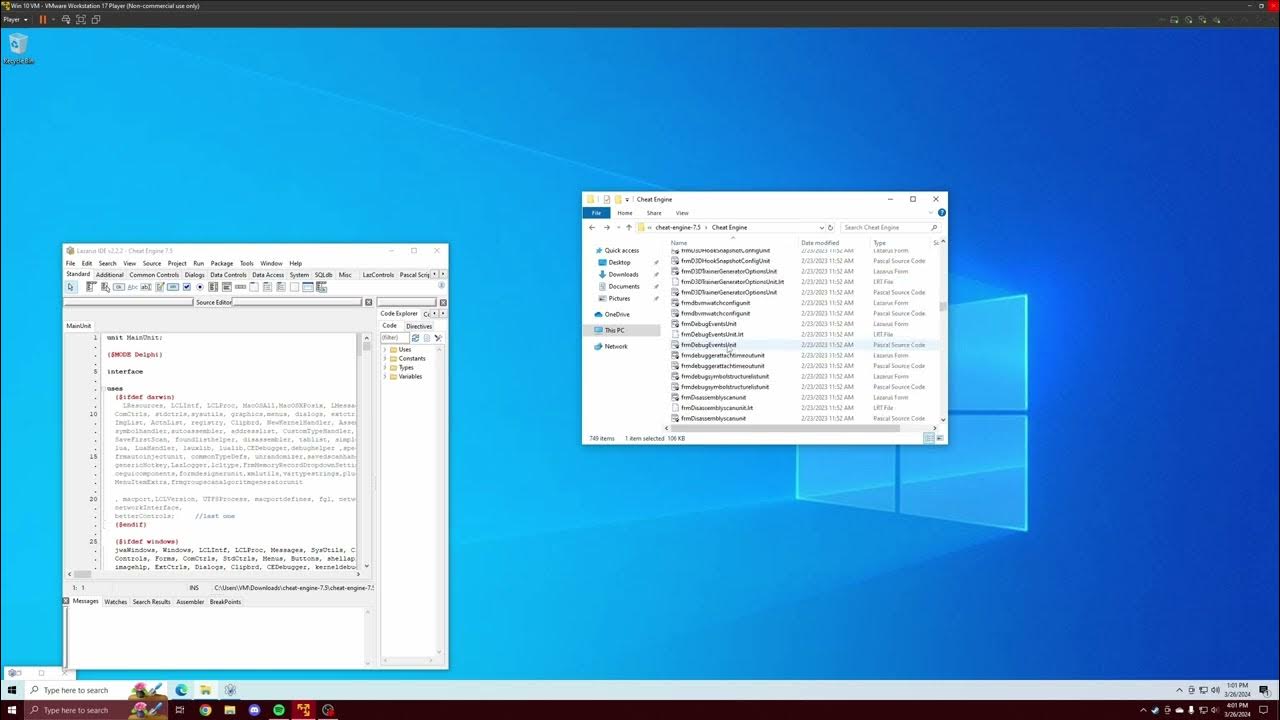

Cheat Engine Built From Source Tutorial | Driver | DBVM | VEH Debugger | Renaming | Error Correction

Cara Membuat Bangun Ruang Tabung Dari Kertas Karton || Jaring Jaring Tabung || Buat Bangun Ruang

5.0 / 5 (0 votes)