BOSCH P-Pump Operation

Summary

TLDRThis video explains the inner workings and maintenance of the P pump, a vital component in heavy-duty machinery like dumpers, mixers, and farm equipment. It covers key functions such as pressurizing fuel, timing fuel delivery, and metering fuel quantity. The video also details how adjustments to the pump, including shim placements and barrel rotations, impact engine performance. Emphasizing the importance of understanding pump mechanics, the video offers insights into ensuring optimal fuel delivery, balancing the pump, and conducting tests for accurate operation at varying engine speeds and loads.

Takeaways

- 😀 The P pump is crucial in various heavy-duty vehicles and equipment, such as those used in construction and agriculture.

- 😀 The P pump has three main functions: pressurizing fuel, timing fuel delivery, and metering the fuel quantity.

- 😀 The pump pressurizes fuel through a plunger and camshaft system, with the fuel only being pressurized after the port is closed.

- 😀 Proper fuel timing depends on adjusting the position of the barrel in relation to the plunger, often with the use of shims.

- 😀 Port closure timing for cylinder number one is used as a reference for setting timing on the other cylinders to ensure equal intervals.

- 😀 The P pump can be phased internally by adjusting the plungers and barrels to achieve equal lift and timing across all cylinders.

- 😀 Metering of fuel delivery is controlled by adjusting the effective stroke of the plunger, determined by the position of the barrel port.

- 😀 The helix in the plunger determines when the port opens and closes, impacting the amount of fuel delivered.

- 😀 Barrel adjustments allow for balancing the pump, ensuring that each cylinder receives equal fuel delivery by rotating the barrel to adjust port opening.

- 😀 The P pump must be tested for equal fuel delivery at various speeds and loads to ensure optimal engine performance.

- 😀 Proper adjustment of the P pump improves engine performance, contributing to smoother operation and more efficient power delivery.

Q & A

Why is the P pump important in heavy-duty applications?

-The P pump is crucial in heavy-duty applications such as construction vehicles, farm equipment, and trucks. It is responsible for pressurizing and delivering fuel efficiently to ensure optimal engine performance in demanding conditions.

What are the three main functions of the P pump?

-The three main functions of the P pump are pressurizing the fuel, timing the fuel delivery, and metering the fuel to control the quantity delivered to the engine.

How does the P pump pressurize the fuel?

-The P pump pressurizes the fuel through a plunger mechanism. As the camshaft rotates, the plunger lifts and moves within the barrel. When the plunger reaches the point of port closure, it begins to build high pressure for fuel delivery.

What is the role of port closure in the fuel timing process?

-Port closure determines when fuel injection begins. When the plunger is lifted and the port closes, high pressure builds, initiating fuel delivery to the engine at the correct timing.

How are timing adjustments made in the P pump?

-Timing adjustments in the P pump are made by changing the position of the barrel using shims. This alters the port closure timing, which controls when fuel is injected into the engine.

What is the purpose of the governor in the P pump system?

-The governor controls the movement of the rack in the P pump, which in turn regulates the fuel quantity delivered by adjusting the rack position based on engine speed (RPM) and load conditions.

What is the significance of balancing the P pump?

-Balancing the P pump ensures equal fuel delivery across all cylinders by adjusting the barrel ports. This helps eliminate discrepancies in engine power, ensuring smooth and efficient engine operation.

How does the helix affect metering in the P pump?

-The helix in the P pump determines when the port opens during the plunger's stroke, which in turn controls the quantity of fuel delivered. A single helix handles smaller plungers, while a double helix is used for larger ones, allowing for greater fuel flow.

What happens when the plunger helix spills fuel earlier in its stroke?

-When the plunger helix spills fuel earlier in its stroke, it results in a shorter effective stroke, delivering less fuel. This is useful for low idle conditions, where less fuel is needed.

How is the P pump tested for performance?

-The P pump is tested at the specified pump speed and rack position to ensure equal delivery of fuel within prescribed limits at both high RPM (full load) and low RPM (light load). This confirms the pump's performance and fuel delivery accuracy.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

What is Predictive Maintenance? - Introduction to Condition Monitoring & Condition Based Maintenance

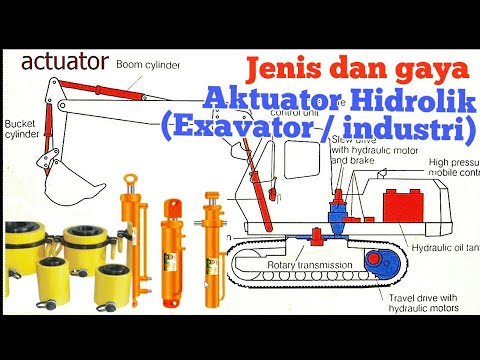

HLP10⚛Hidrolik Actuator merubah energi hidrolik jadi Mekanik sesuai gaya kerjanya

Video Presentasi Dasar Mekanika dan Hidrolika pada alat berat Kelompok 2

Vehicle and equipment biosecurity on farms

Inilah Mesin Dan Alat Berat Untuk Mempercepat Proses Konstruksi

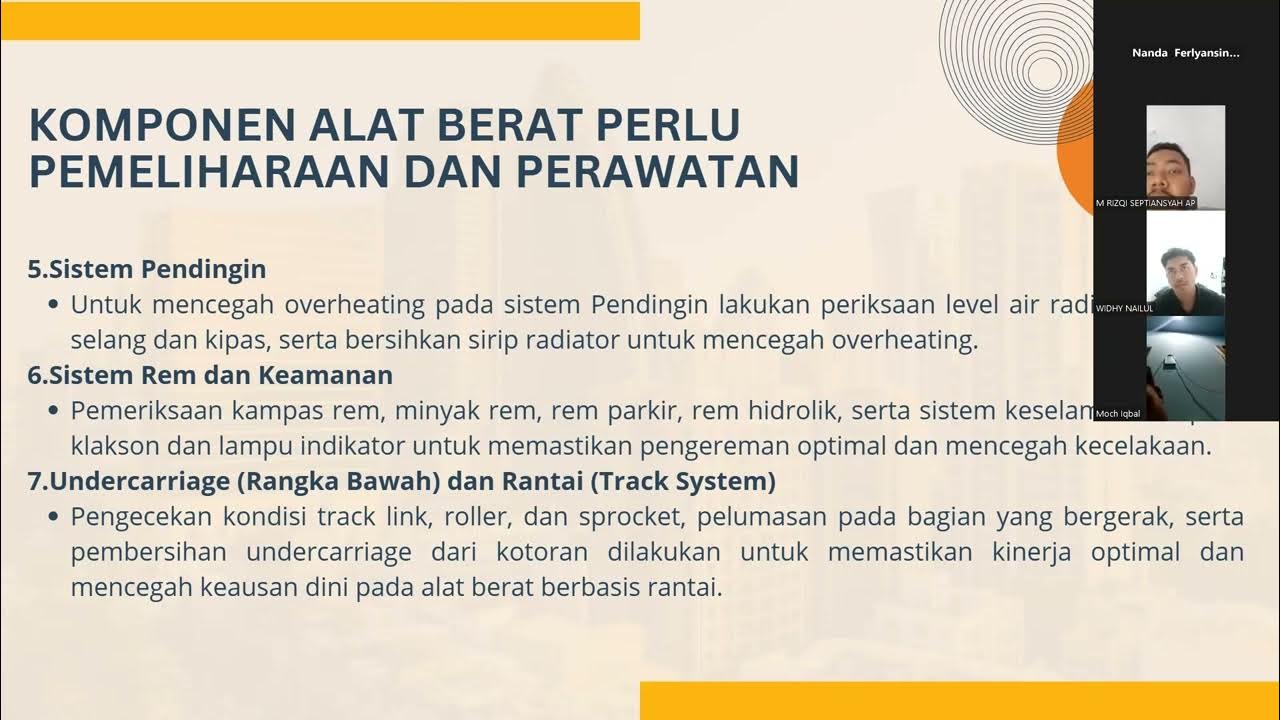

Video Presentasi Kelompok 7 Pemeliharaan dan Perawatan pada Alat Berat

5.0 / 5 (0 votes)