How to Install a Performance Intake Manifold and Replace Gaskets (Dyno PROOF)

Summary

TLDRThis video guide walks through the step-by-step process of installing a performance intake on a vehicle, including the removal of stock components, preparation, and installation of new parts. It highlights the importance of organization during the disassembly process and emphasizes waiting for the RTV to cure before tightening down the intake manifold. The video also covers the coolant system refill and final testing. The dyno results show a 12 horsepower gain, with a significant increase in performance at higher RPMs, making this upgrade a solid improvement for future modifications like a supercharger.

Takeaways

- 😀 Labeling baggies for bolts and parts helps keep track of everything during the disassembly process.

- 😀 Using a magnetic tool can assist in easily removing small studs during the installation process.

- 😀 Allow the RTV (Room Temperature Vulcanizing) sealant to cure for an hour before tightening the intake manifold bolts for optimal sealing.

- 😀 Tighten intake manifold bolts in a crisscross pattern starting from the middle to ensure even pressure and a proper seal.

- 😀 Torque the intake manifold bolts to 20 foot-pounds to prevent leaks and ensure a secure fit.

- 😀 When reinstalling components like the fuel rail and spark plug wires, follow the same procedure for both sides of the engine.

- 😀 Installing the alternator and tightening bolts to 20 foot-pounds is essential for proper functionality.

- 😀 Modifying the alternator bracket may be necessary to accommodate the performance intake manifold.

- 😀 Properly reinstalling the drive belt on the alternator ensures the correct operation of the vehicle's charging system.

- 😀 After reassembly, filling the cooling system with the correct 50/50 antifreeze and water mix is essential for engine performance.

- 😀 The performance intake modification resulted in a 12 horsepower gain, with a significant increase in horsepower at higher RPMs, demonstrating the effectiveness of the upgrade.

Q & A

Why is it important to take pictures of the bolts and parts before disassembling the intake manifold?

-Taking pictures before disassembling helps ensure that all bolts and parts are accounted for during reassembly. This way, you can track exactly where each component goes, making the reinstallation process easier and reducing the risk of mistakes.

What is the purpose of using a magnetic tool when removing studs?

-A magnetic tool helps remove studs easily by attracting and holding onto them, making the process more efficient and reducing the chance of losing small parts like studs.

Why should the RTV cure for an hour before tightening the intake bolts?

-Allowing the RTV (Room Temperature Vulcanizing) sealant to cure for an hour before tightening helps it become more rubbery. This ensures a better seal between the intake manifold and the engine, preventing leaks, especially coolant leaks.

What is the significance of tightening the intake bolts in a crisscross pattern?

-Tightening the intake bolts in a crisscross pattern ensures an even compression of the gasket, which is essential for achieving a proper seal and preventing leaks from forming.

What does the term 'torque down' mean, and why is it important during this process?

-'Torque down' means tightening the bolts to a specific torque value, measured in foot-pounds. This is important to ensure that the bolts are not over-tightened or under-tightened, both of which could lead to leaks or damage to the parts.

Why is it necessary to check for fuel injector and coolant leaks after starting the engine?

-After starting the engine, it's crucial to check for fuel injector and coolant leaks because these components are under pressure. If there are any leaks, they could lead to performance issues, engine damage, or safety hazards.

What effect does the new intake manifold have on the engine's horsepower and torque?

-The new intake manifold led to a gain of 12 horsepower, from 196 to 208 horsepower. It increased torque significantly above 4,000 RPM, particularly at redline, where horsepower increased by 50, showing that the larger intake runners allow more air to flow at higher RPMs.

What might the slight decrease in torque (7 lb-ft) at lower RPMs indicate about the intake manifold modification?

-The slight decrease in torque at lower RPMs suggests that while the new intake might not provide as much low-end torque, it significantly enhances airflow at higher RPMs, leading to better performance at higher engine speeds.

Why is the stock intake manifold reinstalled temporarily instead of the performance throttle body?

-The stock intake manifold is reinstalled temporarily to keep the dyno results focused solely on the performance gains from the intake manifold upgrade, without the additional variable of the throttle body upgrade.

What is the role of RTV in the intake manifold installation process?

-RTV (Room Temperature Vulcanizing) is used as a gasket sealant to create a tight, leak-proof seal between the intake manifold and the engine block. It prevents air and fluid leaks that could affect engine performance.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Cara Service 250 dan 500 jam PC200 Komatsu

BUDGET Chevy GM 88-98 C1500 Truck Rear Disk Brake Conversion EASY! UNDER $400

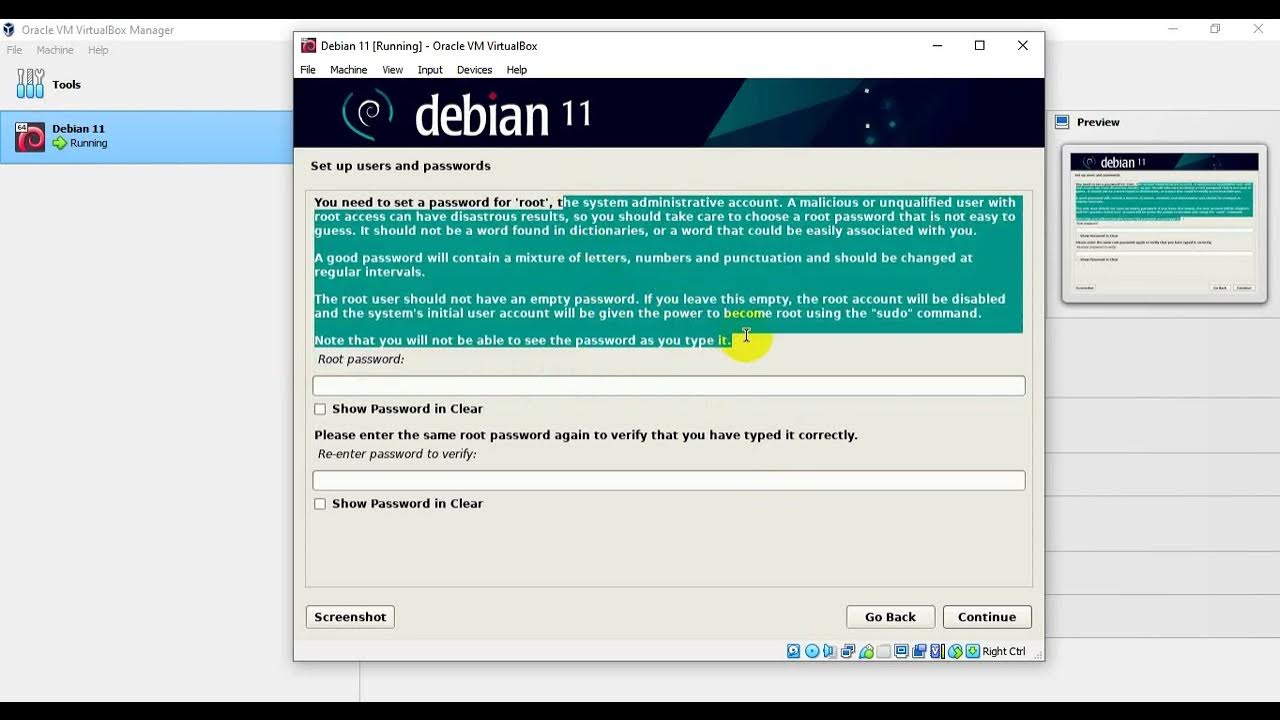

1. Install Debian - Guided Partition

Cara pasang Noken as IN IN di satria fu karbu. step by step lengkap rinci detail. di jamin FAHAM!

Media Ajarku: Instalasi Debian 12 CLI

How to Install Linux on a Virtual Machine using VirtualBox

5.0 / 5 (0 votes)