I Finally Did It! After 8 years I found the PERFECT GEARS

Summary

TLDRThis video showcases the construction of a scale prototype for the Marble Machine 3's drivetrain, an innovative mechanical system that transforms uneven human input into smooth, consistent output power. The project, inspired by Renaissance designs, features helical gears, pedals, and a flywheel to maintain a constant RPM, ensuring tight music performance. After years of development, the creator tests the system, refining it for better precision. The project’s success is highlighted by the machine's ability to play music with perfect tempo, marking a significant milestone in the creator's journey of engineering and creativity.

Takeaways

- 😀 The project is a scale 1:10 prototype of the Marble Machine 3 drivetrain, inspired by Renaissance mechanics.

- 😀 The goal is to build a drivetrain that takes uneven human power input and creates smooth, constant output, producing tight music.

- 😀 Double helical gears are used in the drivetrain for their efficiency, smoothness, and lack of sideways push.

- 😀 The prototype includes parallelogram pedals to provide an even power input and enable both hands to play music while powering the machine.

- 😀 One-way bearings are incorporated to ensure the drivetrain only rotates in one direction, improving efficiency.

- 😀 A flywheel is used to smooth out the uneven power input and create a constant RPM for the music.

- 😀 The weight of the drivetrain is carefully controlled and adjusted, with an innovative carrier to regulate the weight's movement.

- 😀 A ratchet wheel is employed to lift the weight, which in turn drives the gears and helps balance the power distribution.

- 😀 The system allows for constant weight height to ensure smooth and tight music while operating.

- 😀 After rigorous testing, the machine is found to produce music with a much tighter rhythm than human playing, with a perfectly stable tempo.

Q & A

What is the purpose of building the 1:10 prototype of the marble machine 3 drivetrain?

-The purpose of building the 1:10 prototype is to verify the physics of the drivetrain design and test whether it functions as expected in the real world before applying it to the full-size Marble Machine 3.

Why does the creator use double helical gears in the drivetrain?

-Double helical gears are used because they are more efficient, quieter, and smoother in interaction compared to single helical gears. The opposing angles of the gears cancel out sideways forces, leading to smoother and more reliable performance.

What is the significance of the parallelogram pedals in the drivetrain design?

-The parallelogram pedals are significant because they allow for consistent power input to the drivetrain, regardless of how fast the music is playing, and provide the ability to pedal in time with the music while still using both hands for playing instruments.

What role does the flywheel play in the drivetrain system?

-The flywheel serves to smooth out uneven input power from the pedals, converting it into a more constant and consistent output speed, which is essential for keeping the music in time and achieving tight tempo.

What is the purpose of the one-way bearing in the drivetrain?

-The one-way bearing ensures that the drivetrain only spins in one direction, allowing for smooth operation while preventing backward motion, which helps maintain the desired consistency in power delivery.

What is the purpose of the weight and ratchet system in the drivetrain?

-The weight and ratchet system is used to control the input power to the system. By lifting the weight with the ratchet wheel, additional force is generated, which is then used to drive the output gears, ensuring consistent and controlled energy input.

Why does the creator experiment with 3D printing for parts like the shaft?

-3D printing is used to create custom parts such as the shaft because it allows for precise, personalized components that can be easily tested and adjusted in the prototype phase before committing to more permanent materials.

How does the system ensure that the music remains 'tight' or in sync?

-The system remains tight by adjusting the flywheel and weight to maintain a constant input power and speed, with a governor ensuring that the system reaches and maintains a consistent tempo, preventing fluctuations and keeping the rhythm steady.

What is the significance of the governor in the drivetrain system?

-The governor regulates the speed of the flywheel by adjusting the input power, ensuring that the tempo remains constant and the system produces even, consistent output, crucial for tight, in-time music.

What was the creator’s ultimate goal in this project after eight years of work?

-The creator's ultimate goal was to solve the problem of generating even, consistent power input for the drivetrain, ensuring that the music produced by the Marble Machine 3 stays tight and in sync, which was confirmed through successful testing.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

CeramicSpeed DrivEN 99% Efficient Drive Shaft // Chain Free Bike // Eurobike 2018

repulsion motor | repulsion motor in hindi | repulsion motor construction and working | animation

Penyearah tiga fasa

9. OCR A Level (H046-H446) SRL3 - 1.1 Input, output and storage devices

Funções: Noções Básicas (Aula 1 de 15)

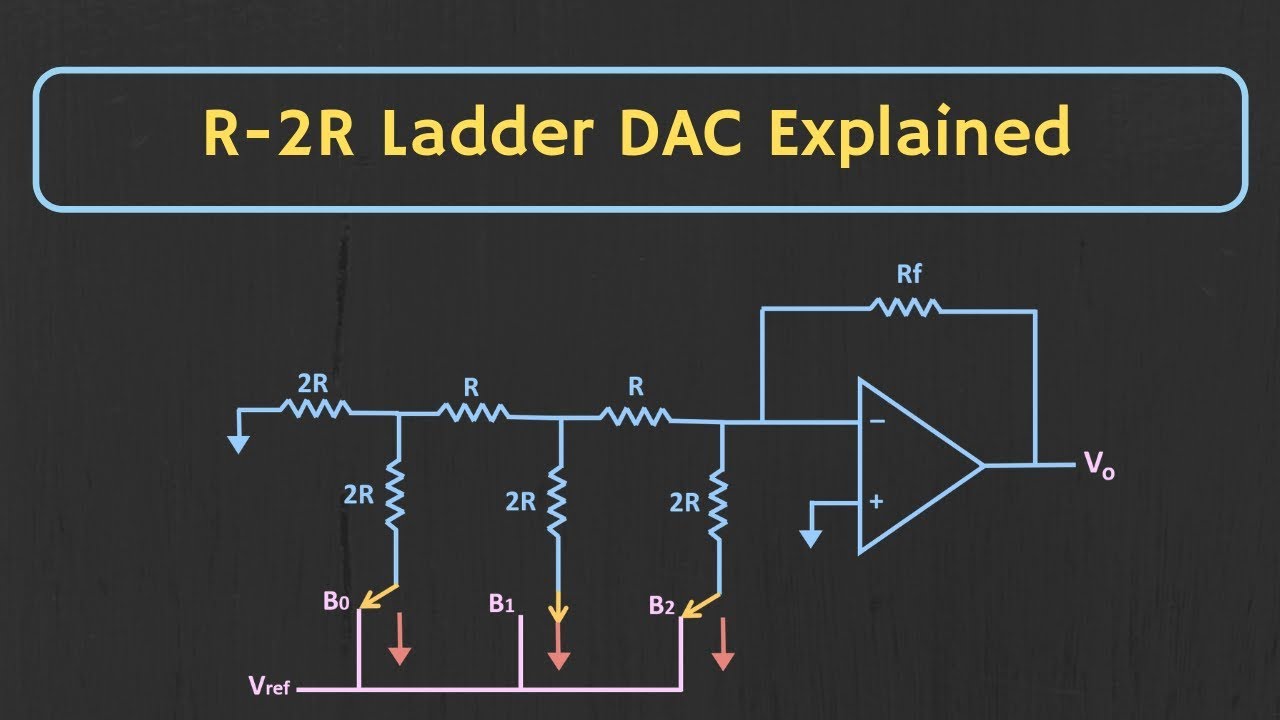

R-2R Ladder DAC Explained (with Solved Example)

5.0 / 5 (0 votes)