Sistem VVT-i (Sistem Pengaturan Katup Secara Elektronik) Bagian 1 #waginothok

Summary

TLDRThe video discusses the Variable Valve Timing Intelligent (VVTI) system, primarily developed by Toyota, as part of the broader topic of electronic valve control in automotive engines. It explores the key concepts of valve timing adjustments through various systems like VVTi, VTEC, and MIVEC, explaining their impact on engine performance and efficiency. The transcript delves into the mechanics of how the VVTI system operates, including the role of electronic control and oil flow in adjusting the timing of intake and exhaust valves. It highlights benefits such as improved engine performance, fuel efficiency, and reduced emissions, offering technical insights into how these systems are constructed and function in modern engines.

Takeaways

- 😀 VVTI (Variable Valve Timing with Intelligence) is a system that allows for dynamic adjustment of the engine's valve timing to optimize performance, fuel efficiency, and emissions.

- 😀 The VVTI system, developed by Toyota, is designed to adjust the intake valve timing based on the engine's speed and load, offering better efficiency compared to traditional fixed valve timing systems.

- 😀 Other car brands have similar systems to VVTI, such as Honda's VTEC (Variable Valve Timing and Lift Electronic Control), Mitsubishi's MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System), and Hyundai's CVVT (Continuous Variable Valve Timing).

- 😀 The main advantage of VVTI is that it allows for variable valve timing, which helps improve engine torque by up to 10% and fuel efficiency by approximately 6%.

- 😀 VVTI also contributes to reducing NOx (nitrogen oxide) emissions by varying the valve timing to optimize combustion.

- 😀 The system works by adjusting the position of the intake camshaft, either advancing or retarding it, depending on the engine’s needs.

- 😀 VVTI systems are controlled electronically by the Engine Control Unit (ECU), which receives data from sensors such as the crankshaft position sensor (CKP) and camshaft position sensor (CMP).

- 😀 Unlike conventional engines where valve timing is fixed, VVTI engines have the ability to vary valve timing dynamically in real-time, leading to a more efficient engine operation.

- 😀 The oil control valve plays a key role in shifting the intake camshaft's position, with the ECU controlling its operation based on input from various sensors.

- 😀 By adjusting the camshaft's position, the VVTI system can optimize engine performance across different RPM and load conditions, allowing for both improved power and better fuel economy.

Q & A

What is VVTI, and how does it function?

-VVTI stands for Variable Valve Timing with Intelligence. It is an electronic valve control system that allows for varying the timing of the intake and exhaust valves to optimize engine performance. Developed by Toyota, it helps improve power output and fuel efficiency by adjusting valve timing according to engine speed and load.

What are the different variable valve timing systems mentioned in the script?

-The script mentions several variable valve timing systems: VVTI (Variable Valve Timing with Intelligence) by Toyota, i-VTEC by Honda, MIVEC by Mitsubishi, and CVVT (Continuous Variable Valve Timing) developed by Hyundai.

How does the VVTI system benefit an engine?

-The VVTI system provides several benefits, including improved engine performance by about 10%, fuel consumption reduction by around 6%, and decreased emissions, particularly NOx (Nitrogen Oxides) by up to 40%. These advantages are achieved through the ability to vary valve timing electronically.

What is the main function of the camshaft in a conventional engine?

-In a conventional engine, the camshaft controls the timing of valve opening and closing. The valve timing remains fixed, meaning that the intake valve opens and closes at the same points in the engine cycle, regardless of RPM or load.

What causes engine instability in conventional systems at low RPM?

-At low RPM, the intake valve in a conventional engine may open too early, causing exhaust gases to re-enter the intake manifold. This leads to incomplete combustion and unstable engine operation. To compensate, the RPM is increased, but this results in higher fuel consumption.

How does VVTI solve the issue of engine instability in conventional engines?

-VVTI adjusts the valve timing, allowing the intake valve to open and close at different points depending on the engine's RPM and load. This flexibility helps optimize combustion, preventing the overlap of exhaust gases and intake air at low RPM, thereby stabilizing engine performance.

What role do sensors play in the VVTI system?

-Sensors, such as the crankshaft position sensor (CKP) and camshaft position sensor (CMP), provide real-time data to the engine control unit (ECU). These sensors help the ECU determine the optimal valve timing based on engine conditions, and the ECU adjusts the valve timing through the oil control valve accordingly.

How does the oil control valve contribute to the VVTI system?

-The oil control valve directs the flow of oil to the camshaft adjuster, enabling the camshaft to rotate and vary the valve timing. This adjustment is controlled by the ECU, which signals the oil control valve to either advance or retard the camshaft timing based on the engine's needs.

What is the difference between conventional and VVTI systems in terms of valve timing?

-In a conventional engine, valve timing is fixed and cannot be altered based on engine conditions. In contrast, the VVTI system allows the valve timing to be adjusted dynamically, which helps optimize engine performance, fuel efficiency, and emissions across different driving conditions.

What are the components of the VVTI system, and where are they located?

-The VVTI system consists of several components, including the camshaft (which controls valve timing), the oil control valve (which directs oil flow to adjust camshaft position), and various sensors (such as the CKP and CMP sensors) that monitor engine parameters. These components work together to adjust the valve timing based on real-time data, improving engine efficiency and performance.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Pemilik Avanza Wajib BANGGA !! | Cara kerja VVT-i Teknology SEJUTA UMAT Dari Toyota ( 2Jz Juga Pake)

Memahami Sistem Kerja VVT-i (bagian 2) #waginothok

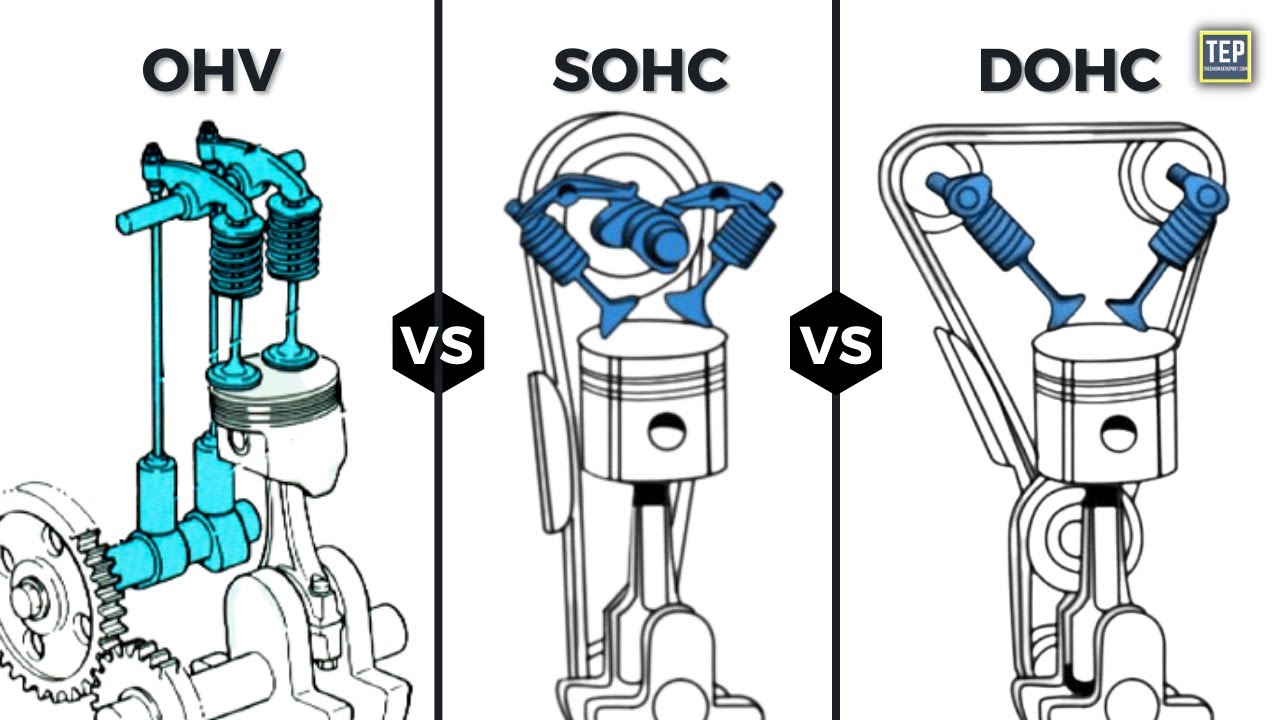

Which is the Best Engine Valvetrain Design? OHV, SOHC, DOHC or Flathead | Pros and Cons

Toyota Hilux D-4D (2010) - P0400 EGR Flow

SOHC VS DOHC | Yang Manakah Yang Kita Butuhkan ? (Over Head Camshaft) Part-2

BELAJAR DARING TBSM PERAWATAN BERKALA MEKANISME KATUP

5.0 / 5 (0 votes)