Rotary Pumps

Summary

TLDRThe video explains the different types of rotary pumps, including screw pumps, gear pumps, lobe pumps, and vane pumps. It highlights the mechanisms behind each pump, such as how screw pumps use intermeshing threads to create positive pressure, and how gear pumps utilize side-by-side gears to transfer liquid. Lobe pumps are described as having rotors that interact in a continuous motion, while vane pumps use rotating pistons to transfer fluid. The video also discusses the appropriate applications for each pump type, from handling low viscosity liquids to vacuum services, and their suitability for various industries such as food and beverage processing.

Takeaways

- 😀 Rotary pumps come in four types: screw pumps, gear pumps, lobe pumps, and vane pumps.

- 😀 Screw pumps work through the intermeshing of threads on rotors and the close fit of surrounding housing, creating multiple moving seals.

- 😀 Gear pumps use side-by-side external gears driven by a motor to rotate and transfer trapped liquid from the inlet to the outlet.

- 😀 Lobe pumps feature rounded rotors in contact with each other, carrying fluid between lobes in a similar fashion to gear pumps.

- 😀 Unlike gear pumps, lobe pumps require timing between the rotors, as one rotor drives the other.

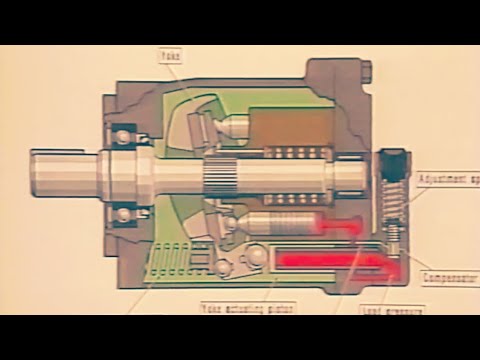

- 😀 Vane pumps operate with rotating pistons in a cylinder, creating fluid movement during half of the revolution.

- 😀 The eccentricity of the ring in vane pumps increases piston stroke length, allowing for more fluid transfer.

- 😀 Gear pumps are suitable for handling more viscous fluids, while sliding vane pumps are ideal for low-viscosity, non-lubricating liquids.

- 😀 Sliding vane pumps are not ideal for handling dirty or gritty liquids due to their internal structure.

- 😀 Vane pumps are most suited for low-viscosity, non-lubricating fluids and are commonly used in vacuum services.

- 😀 Lobe pumps can handle both low and high viscosity fluids, making them versatile for food and beverage processing.

Q & A

What are the four types of rotary pumps mentioned in the script?

-The four types of rotary pumps mentioned are screw pumps, gear pumps, lobe pumps, and vane pumps.

How does a screw pump work?

-A screw pump works by intermeshing threads on rotors and the close fit of the surrounding housing, creating sets of moving seals between the pump inlet and outlet. This provides positive pressure and continuous flow.

Why is a gear pump named as such?

-A gear pump is named because it has gears that are side by side, with an external drive gear driven by a motor. These gears rotate in opposite directions, transferring the trapped liquid between the gear teeth from the inlet side to the outlet side.

What is unique about the design of a lobe pump?

-The lobe pump has rotors with a rounded shape, allowing them to remain in continuous contact with each other as they rotate. This design helps in transferring fluids between the rotor lobes, similar to how a gear pump works.

What is the primary application of vane pumps?

-Vane pumps are primarily used in applications where fluids need to be transferred under varying conditions. They include a rotating cylinder with pistons arranged radially around it, and they are suitable for both clean and viscous fluids.

What is the role of the 'spring' in a vane pump?

-The spring in a vane pump pushes the pistons against the inner surface of a stationary ring. This action ensures that the pistons are in constant contact with the cylinder, effectively moving fluid during the rotation.

What type of fluids are screw pumps ideal for?

-Screw pumps are ideal for handling thick, viscous fluids, including oils and other thick liquids, due to their ability to provide a smooth, consistent flow without breaking down the fluid.

What are some applications of gear pumps?

-Gear pumps are typically used in applications that require handling thicker fluids such as oils, chemicals, and fuels. They are suitable for a variety of industries, including automotive, food processing, and chemical manufacturing.

What types of fluids can lobe pumps handle?

-Lobe pumps are versatile and can handle both low and high-viscosity fluids. They are particularly suitable for food and beverage processing due to their ability to handle delicate fluids without damaging them.

What is a key limitation of sliding vane pumps?

-Sliding vane pumps are not suitable for handling dirty or gritty liquids. They are best used for clean, low-viscosity, non-lubricating fluids, and are typically employed in vacuum service applications.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Types of Pumps | All in One Guide to Industrial Pump Types

Hydraulic Training Series - Chapter 2 - Hydraulic Pumps

Pumps Types - Types of Pump - Classification of Pumps - Different Types of Pump

Part 1: Vacuum Systems - G. Jensen

Yuk Belajar Tentang Pompa-Pompa di atas Kapal (Part 2) - Lilin Tua #pompa #kapal #belajar #pelaut

I POMPA AIR PART 1

5.0 / 5 (0 votes)