Pre-Charge Circuits for Lithium-Ion Battery Packs

Summary

TLDRIn this video, Erik Stafl explains the importance of a precharge circuit in lithium-ion battery packs. He highlights how it ensures safety by preventing large inrush currents that could damage components like capacitors or contactors. Stafl breaks down the precharge process, demonstrating how it uses a smaller resistor to limit current and gradually charge the system's capacitor. He discusses key concepts like time constants, resistor selection, and fault detection, emphasizing the role of a Battery Management System (BMS) in maintaining the system’s safety. Overall, the precharge circuit is vital for both performance and longevity.

Takeaways

- 😀 Precharge circuits are essential for lithium-ion battery packs to enhance safety and longevity.

- 😀 A precharge circuit consists of a smaller disconnect switch, a resistor, and sometimes a fuse, working in parallel with the main disconnect switch.

- 😀 Without a precharge circuit, large inrush currents can damage components like capacitors or the main contactor, potentially causing sparking or welding.

- 😀 A precharge circuit helps limit current flow by using a resistor, providing a controlled, low-current charging process.

- 😀 Inrush current is limited to safe levels by the resistor in the precharge circuit, preventing damage from large current surges.

- 😀 The precharge process follows an RC (resistor-capacitor) time constant, gradually charging the capacitor to the battery's voltage.

- 😀 The RC time constant (tau) is calculated by multiplying the resistance and capacitance, and it determines how long the precharge takes.

- 😀 After three time constants (approximately 1.2 seconds in the example given), the capacitor voltage is typically within 5% of the battery voltage, allowing the main contactor to close.

- 😀 Reducing the resistor value speeds up the precharge time, while increasing the resistance slows it down, but thermal limits must be considered.

- 😀 The resistor dissipates heat during the precharge process, and power dissipation is highest when the voltage difference between the battery and capacitor is greatest.

- 😀 Precharge circuits, when coupled with a battery management system (BMS), help detect faults such as short circuits, incorrect polarity, or excessive precharge times, raising alarms when necessary.

Q & A

What is the purpose of a precharge circuit in a lithium-ion battery pack?

-A precharge circuit is essential for limiting inrush current when connecting a lithium-ion battery to external systems, preventing damage to both the battery and the external components. It enhances safety and extends the longevity of the system.

Where is the precharge circuit located in a high-voltage battery pack?

-The precharge circuit is connected in parallel with the main disconnect switch in the battery pack. It consists of a smaller disconnect switch, a resistor, and sometimes a fuse.

Why is there a need for a precharge circuit in systems with significant capacitance?

-External systems connected to a battery, such as inverters or grid tie systems, often contain large capacitances. Without a precharge circuit, these capacitances can cause dangerous inrush currents when the battery is connected, leading to potential damage and safety hazards.

What would happen if the precharge circuit were not used when closing the main disconnect switch?

-Without a precharge circuit, closing the main disconnect switch would result in a large inrush current, potentially thousands of amps, which could lead to sparking, welding of the contactor, or damage to the capacitor bank due to the high current flow.

How does the precharge circuit work to prevent inrush current?

-The precharge circuit includes a resistor that limits the current flow when the precharge switch is closed, allowing the capacitor to charge slowly instead of causing a large surge of current. This helps avoid excessive current flow and associated risks.

What is the significance of the RC time constant in a precharge circuit?

-The RC time constant determines how quickly the capacitor charges. It is defined by the product of resistance and capacitance, and it influences how long the precharge circuit takes to charge the capacitor to a level where the main disconnect switch can be closed safely.

How is the precharge time calculated based on resistance and capacitance?

-The precharge time is determined by the RC time constant, which is the product of the resistance and capacitance. For instance, if the resistance is 1000 ohms and the capacitance is 400 microfarads, the time constant is 400 milliseconds. Three time constants (1.2 seconds in this example) are typically enough for the voltage to rise to 95% of the battery voltage.

Why is it not advisable to use a very small resistance value in a precharge circuit?

-Using a very small resistance value would reduce the precharge time, but it could lead to excessive heat generation in the resistor due to high power dissipation. This could damage the resistor or other components. A balance between precharge time and thermal safety is necessary.

What happens to the heat dissipation in the precharge resistor over time?

-Heat dissipation in the precharge resistor is highest at the beginning of the charging process, when the voltage difference between the battery and the capacitor is greatest. As the voltage delta decreases, the current flow and heat generation also decrease, making the system safer over time.

How can a battery management system (BMS) detect faults in the precharge circuit?

-The BMS can monitor the charging behavior of the capacitor. If the voltage does not rise as expected, or if the current flow is abnormal, the BMS can trigger a fault flag. For instance, if the capacitor charges too slowly or not at all, the BMS might detect a short circuit or incorrect capacitance and prevent the main switch from closing.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Make your own LED Battery Level Indicator

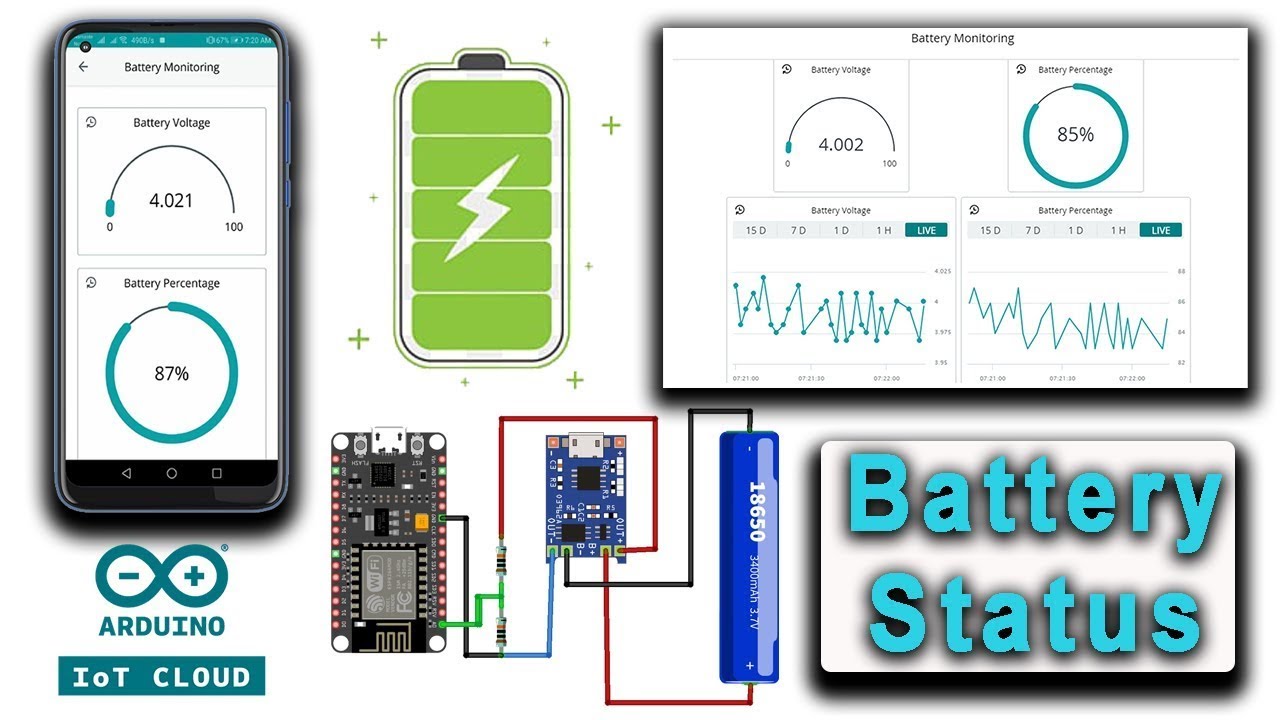

IoT Based Battery Monitoring System Using ESP8266 & Arduino IoT Cloud

Lithium-Ion Batteries Assembly Business | Industrial Tour |

The science inside lithium-ion batteries - with the Faraday Institution

Cara Kerja dan Perkembangan TEKNOLOGI BATERAI

DJI Phantom 3 Battery Recovery

5.0 / 5 (0 votes)