CypCut Software Tutorial English | Cypcut Laser Cutting | Complete 1

Summary

TLDRThis video offers an in-depth introduction to Safcat, a software designed for laser cutting machines in the fabrication industry. It guides viewers through the software's interface, highlighting key features such as file management, graphic processing, nesting functions, and optimization tools. The tutorial covers diagnostic tools, including gas pressure calibration and CNC functions, and demonstrates how to generate and manipulate graphics. The presenter also discusses the importance of regular backups and provides insights into machine diagnostics and performance optimization. The video concludes with an invitation for viewers to share their laser machine issues or contact the team for support.

Takeaways

- 😀 Safcat is a software designed for laser cutting machines in the fabrication industry.

- 🔄 The software is frequently updated, so users may experience differences from the version shown in the video.

- 🖥️ The interface is divided into several bars including a processing control bar and a graphics processing bar.

- 📁 The 'File' menu allows for creating new files, opening saved files, and importing DXF format graphics compatible with CAD.

- 📑 The 'Nesting' function is used to import external nesting files and standard parts from the built-in library.

- 📊 'Report' features provide an estimation of processing time, cutting length, and generate printable reports.

- 🛠️ 'User Sighting' includes optimization for imported graphics and settings for unit grouping and layer mapping.

- 🔧 'Backup' helps store platform configuration, tool PLC, and global parameters into a single file for safekeeping.

- 🛡️ 'Diagnosis' encompasses various monitors and tests including card monitor, extended I/O monitor, gas pressure calibration, and burning tests.

- 🔍 'Extended I/O Monitor' is used for external functions, such as enabling autofocus in cutting heads or managing large machine tables.

- 📐 The software allows for quick generation of basic graphics and supports importing and parameter setting for standard parts.

- 🎨 Graphic editing tools include selection, note marking for non-editing, manual sorting, panning, and zooming.

Q & A

What is the purpose of the software Safcat for laser cutting machines?

-Safcat is a software designed for fabricating laser cutting machines, providing functionalities for processing control, graphics processing, and various other features to aid in the operation and optimization of the machine.

How is the Safcat software interface divided?

-The Safcat software interface is mainly divided into several bars: a processing control bar on the right, a graphics processing bar on the left, and other sections for different functionalities.

What file operations can be performed using the 'File' dropdown menu in Safcat?

-The 'File' dropdown menu allows users to create a new file, open a previously saved file, and import graphics in DXF format or from third-party software.

What is the nesting function in Safcat used for?

-The nesting function in Safcat is used to import external nesting files and standard parts from the built-in library, which helps in organizing and optimizing the layout for cutting operations.

What does the 'Task Report' feature in Safcat provide?

-The 'Task Report' feature in Safcat allows users to estimate the processing time of the current graphics, the total length of the cutting, and empty moments, generating a report that can be printed out.

What are the two major components of the 'User Parameter Setting' in Safcat?

-The 'User Parameter Setting' in Safcat contains two major components: optimization, which automatically performs graphics optimization upon import, and the sighting of the imported unit, which allows for various adjustments such as exploding groups and converting attacks into curves.

What is the role of the 'Backup' function in Safcat?

-The 'Backup' function in Safcat helps store the platform configuration, tool PLC, and global parameters into one file, which is useful for manufacturers to maintain and protect against data loss.

What does the 'Card Monitor' feature in Safcat's 'Diagnosis' section allow users to perform?

-The 'Card Monitor' feature allows users to perform a single pause test, sending a thousand passes to the X-axis and receiving encoder feedback to check if the encoder is functioning normally.

What is the purpose of the 'Extended I/O Monitor' in Safcat?

-The 'Extended I/O Monitor' is an external function in Safcat that enables additional capabilities such as autofocus cutting head functionality or handling large machine tables when output parts for partition removal are insufficient.

What is the 'Gas D Correction' feature in Safcat used for?

-The 'Gas D Correction' feature in Safcat is used for calibrating the gas pressure valve, which is essential for ensuring the correct gas pressure is applied during the cutting process.

How can users generate simple graphics or import standard parts in Safcat?

-Users can quickly generate simple graphics such as straight lines, circles, rectangles, and stars, or import standard parts by setting the parameters in Safcat, which also supports importing DXF layers.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Common 13 Types of Sheet Metal Fabrication Techniques

Cours réseaux N° 1 | Généralités sur les réseaux (Première partie) Par Dr MA.RIAHLA

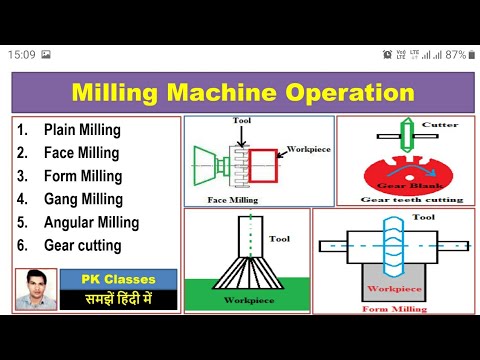

Milling Machine Operations (हिन्दी)

What is a Safezone 3 Area Laser Scanner?

Product Review - Creality Falcon 2 Laser Engraver and Cutter

Mengoperasikan Mesin Perkakas Konvensional - Teknik Mekatronika

5.0 / 5 (0 votes)