Material Handling Safety: Best Practices for Moving and Storing Materials

Summary

TLDRMaterial handling is crucial in many workplaces, but improper handling can lead to serious injuries and accidents. This training covers essential safety practices, including the use of proper equipment like forklifts, dollies, and PPE, as well as techniques to prevent manual handling injuries. Emphasis is placed on ergonomics, maintaining equipment, and safely managing hazardous materials. The training also highlights the importance of emergency preparedness and response, ensuring workers are equipped to handle accidents, fire hazards, and spills. By adhering to these guidelines, workplaces can maintain safety, productivity, and employee well-being.

Takeaways

- 😀 Material handling is a vital yet risky function in many workplaces, and proper training is essential to prevent accidents and injuries.

- 😀 Handling bulky, awkwardly shaped, or hazardous materials requires extra care to minimize risks and damage to property.

- 😀 Safety equipment, such as dollies, carts, and straps, should be used to assist in moving heavy items, while personal protective equipment (PPE) like gloves and safety shoes are essential for worker protection.

- 😀 Forklifts come in seven different classes, each designed for specific tasks. Proper training and awareness of weight limits are crucial to avoid injuries.

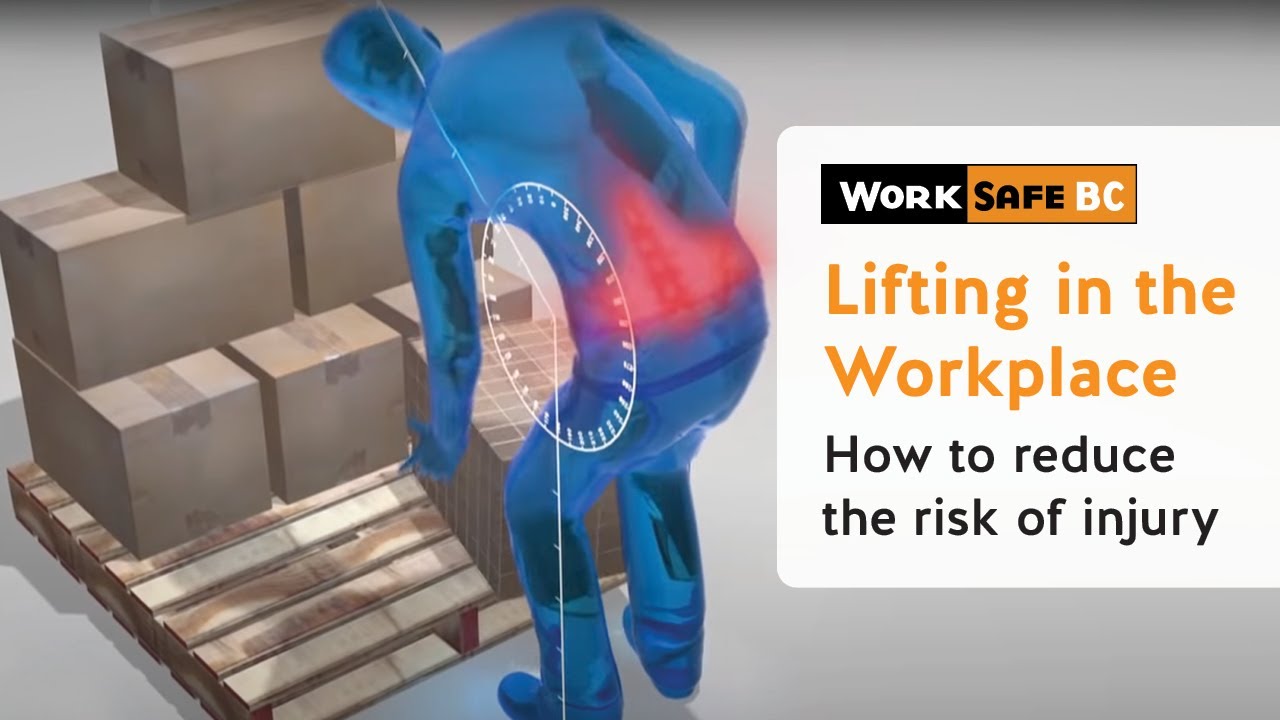

- 😀 Various manual handling techniques, such as lifting with the legs instead of the back, should be used to prevent musculoskeletal injuries like back pain and hernias.

- 😀 Repetitive motions and awkward postures can cause long-term injuries, so it's important to take breaks and avoid positions that strain the body.

- 😀 Ergonomics play a key role in preventing musculoskeletal disorders (MSDs). Employers should evaluate tasks for ergonomic risks and make necessary adjustments.

- 😀 Workers should receive specialized training for handling hazardous materials, including understanding the risks of exposure to toxic chemicals, and using the correct PPE.

- 😀 Emergency preparedness is vital. Employees should be trained to respond to accidents, including handling injuries, fires, and hazardous spills.

- 😀 Proper equipment maintenance is necessary to ensure safe operation. Workers should inspect equipment daily and report any defects to prevent accidents.

- 😀 OSHA compliance, which includes specific training for hazardous material handling and specialized equipment, helps ensure a safer work environment and adherence to safety regulations.

Q & A

What is the primary focus of this training?

-The primary focus of this training is to provide general guidelines and best practices for safe material handling, specifically in the context of moving and storage operations.

Why is material handling considered a source of injuries and accidents?

-Material handling involves dealing with various bulky, awkwardly shaped, or hazardous materials, which can lead to accidents and injuries if not handled correctly. This is why proper safety measures and equipment are crucial.

What role do personal protective equipment (PPE) play in material handling?

-PPE, such as gloves, safety shoes, hard hats, and safety glasses, are essential in protecting workers from potential hazards associated with material handling. They help reduce the risk of injury during operations.

What are the seven classes of forklifts, and why are they important?

-The seven classes of forklifts are designed for specific types of work and operations. Understanding which forklift is suitable for a given task is crucial for safe operation and minimizing accidents.

How can workers reduce the risk of injury when using hand trucks and dollies?

-Workers should be trained to use hand trucks and dollies correctly, following proper procedures to avoid accidents or damage. This includes understanding weight limits, proper lifting techniques, and using equipment suited for the load.

What is the importance of performing daily equipment inspections?

-Daily equipment inspections are critical to ensure that the tools are in good working condition, preventing accidents caused by defects. If any defects are found, they should be reported immediately, and the equipment should not be used until repaired.

What are the risks of manual material handling, and how can they be minimized?

-Manual handling of heavy materials can lead to injuries like back pain, strains, and sprains. To minimize these risks, workers should use proper lifting techniques, avoid awkward postures, and use mechanical aids whenever possible.

What are musculoskeletal disorders (MSDs), and how are they related to material handling?

-MSDs are injuries affecting muscles, tendons, ligaments, and nerves due to repetitive movements or improper handling techniques. In material handling, these disorders often occur from lifting heavy items, repetitive motions, or awkward postures.

What is the significance of ergonomics in preventing injuries in material handling?

-Ergonomics focuses on designing work environments and tasks to fit the physical abilities of workers. By applying ergonomic principles, workplaces can prevent musculoskeletal disorders (MSDs) and reduce the risk of injury.

What additional risks are involved when handling hazardous materials, and what training is required?

-Hazardous materials pose physical and health risks, such as explosions, respiratory problems, and skin irritation. Workers handling these materials must receive specialized training on recognizing hazards, using appropriate PPE, and safely managing the materials, including handling, storing, and disposing of them properly.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)