What is RTU?

Summary

TLDRThis video compares Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs), focusing on their unique features and advantages. RTUs are rugged, reliable devices designed for remote, harsh environments like offshore oil rigs and mountaintops, offering robust communication options and backup power. They are easier to program in some cases, with web interfaces and pre-configured modules, but can require specialized skills for certain programming languages. While PLCs are more affordable, RTUs excel in environmental tolerance, making them ideal for extreme conditions. The video encourages viewers to explore further training on PLC programming at RealPars.com.

Takeaways

- 😀 RTUs (Remote Terminal Units) are microprocessor-based devices that monitor and control field devices, connecting to SCADA systems.

- 😀 Unlike PLCs, RTUs are considered more rugged and better suited for extreme environments, such as remote locations and offshore oil rigs.

- 😀 While PLCs are generally cheaper, RTUs can be more reliable in harsh environments, potentially justifying a higher initial cost.

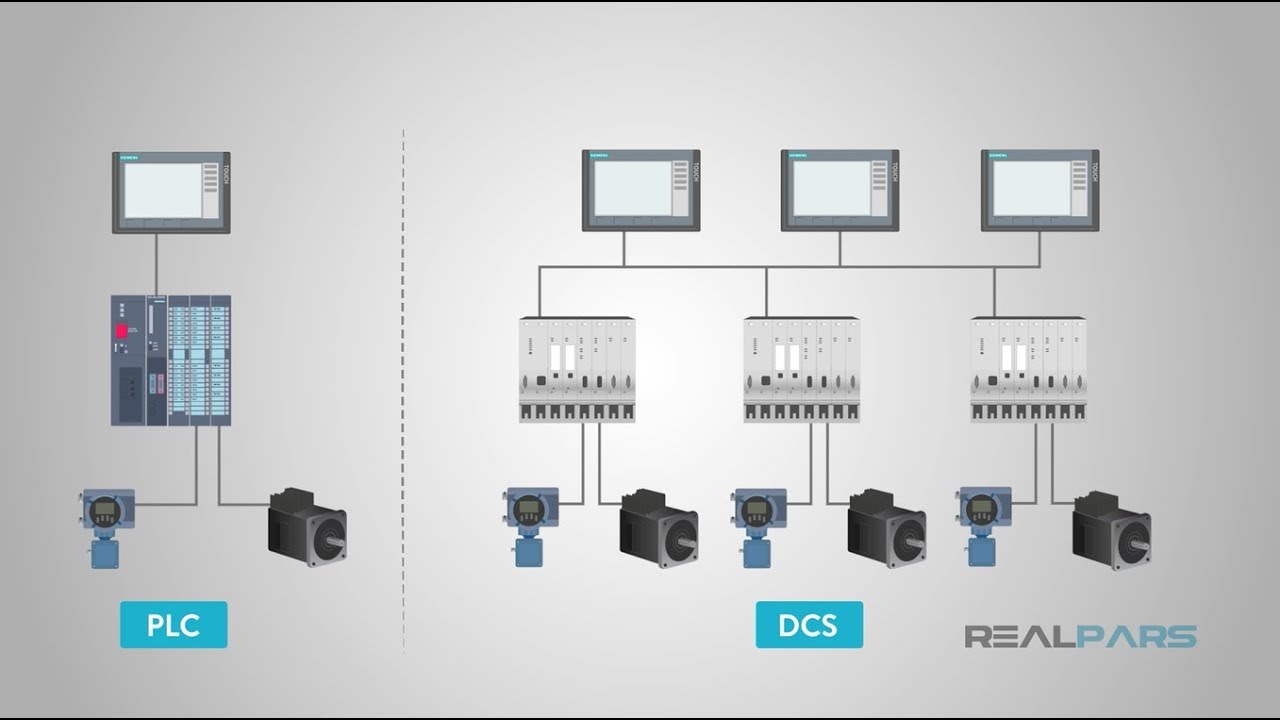

- 😀 Both RTUs and PLCs offer similar capabilities in terms of I/O, communication modules, and process control with minimal operator intervention.

- 😀 RTUs offer programming flexibility through simple web interfaces or preprogrammed modules, which can be easier to configure compared to PLCs.

- 😀 Some RTUs are programmed in languages like Basic, Visual Basic, and C#, while others use languages common to PLCs, such as Ladder Logic and Structured Text.

- 😀 One of the key advantages of RTUs is their ability to withstand extreme environmental conditions, including temperature and remote locations.

- 😀 RTUs are commonly used with radio, microwave, and satellite communication systems, enabling reliable data transfer from very remote sites.

- 😀 RTUs often come with backup power options like solar power and battery charging circuits, ensuring they continue to operate during power outages.

- 😀 Modern PLC and PAC systems have caught up in many areas, reducing the gap in capabilities between PLCs and RTUs, except in environmental tolerance.

- 😀 The real advantage of RTUs lies in their robustness in remote and harsh environments, a feature not easily matched by other control systems.

Q & A

What does RTU stand for?

-RTU stands for Remote Terminal Unit, and it is sometimes referred to as Remote Telemetry Unit or Remote Telecontrol Unit.

What is the main function of an RTU?

-An RTU is a microprocessor-based device used to monitor and control field devices. It connects to plant control or SCADA (Supervisory Control and Data Acquisition) systems for real-time monitoring and control.

How does an RTU differ from a PLC in terms of price?

-RTUs are typically more expensive than PLCs, but they are considered more rugged and durable. This durability can justify the higher initial cost in the long term.

Can both RTUs and PLCs have similar I/O capabilities?

-Yes, both RTUs and PLCs have multiple types of I/O (inputs and outputs), as well as various communications modules. They can both be used to automate processes with minimal operator intervention.

What are the main programming advantages of an RTU over a PLC?

-RTUs can sometimes be programmed through simple web interfaces or specialized setup software. Additionally, some RTUs have pre-programmed modules, making configuration easier compared to PLCs, which require specific programming languages like ladder logic or structured text.

What programming languages might be used for RTUs?

-RTUs may be programmed in languages such as Basic, Visual Basic, C#, or even the same languages used for PLCs, like Ladder Logic and Structured Text.

How do RTUs perform in extreme environmental conditions compared to PLCs?

-RTUs are known for their ruggedness and are designed to perform in extreme environmental conditions, such as extreme temperatures or remote locations. They are often used in situations where PLCs might not be able to function reliably.

What types of communication do RTUs use?

-RTUs frequently use radio, microwave, and satellite communications, allowing them to transmit data from remote locations like offshore oil rigs or distant sites where conventional communication might be challenging.

What is the backup power option for RTUs, and how does it compare to PLCs?

-Many RTUs come with backup power systems, such as solar-powered batteries, ensuring continuous operation during power outages. While PLCs also use uninterruptible power supplies (UPS) for backup, the RTU's integrated backup charging circuit provides additional advantages.

Are there any significant advantages of RTUs over PLCs in modern applications?

-The main advantage of RTUs over PLCs is their ability to handle extreme environmental conditions, such as extreme temperatures and remote locations. However, with advancements in technology, modern PLCs and PACs have closed the gap in many areas, including communications, backup power, and environmental tolerance.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

What is RTU? | Remote Terminal Unit

Programable Logic Controller Basics Explained - automation engineering

What is the Difference Between PLC and DCS?

When to use PLC ,DCS & SCADA | PLC vs DCS vs SCADA Selection Guide

Electrical Review - PLC Basics Part 1

Nozioni base sui PLC ( Controllore Logico Programmabile)

5.0 / 5 (0 votes)