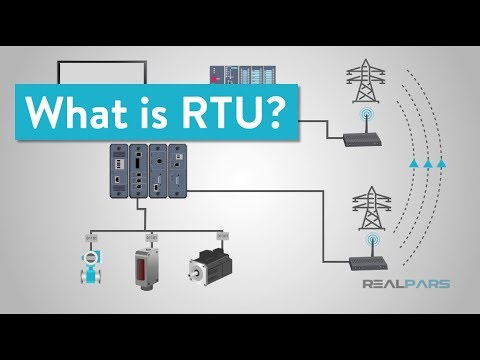

What is RTU? | Remote Terminal Unit

Summary

TLDRThis script introduces Remote Terminal Units (RTUs) as robust electronic devices for monitoring remote industrial sites without electricity or wired connections. They automate processes, gather data from sensors, and communicate with a master control station using protocols like DNP3 or Modbus. RTUs are self-sufficient, with flexible power options, and are designed for harsh environments, contrasting with PLCs which are better suited for local, controlled areas.

Takeaways

- 📡 **RTU Definition**: An RTU (Remote Terminal Unit) is a standalone microprocessor-based device used for monitoring and controlling remote industrial sites.

- 🔌 **Independence**: RTUs can operate independently without needing input from a master controller, automating processes with field equipment.

- 🚨 **Monitoring Capabilities**: They enable reliable monitoring of digital and analog parameters from various field equipment at remote locations.

- 🌐 **Data Processing**: RTUs perform data processing, converting raw data into a transmittable format, which can be accessed via a web interface.

- 📱 **Remote Access**: Operators can monitor and control RTUs remotely through a web interface, reducing the need for physical visits to remote sites.

- 🔔 **Alerts and Notifications**: RTUs can send automatic alerts via phone calls, SMS, or emails in case of failures or predefined threshold breaches.

- 📊 **Centralized Control**: For multiple RTUs, a central master station can be used for efficient monitoring and control of the entire system.

- 📡 **Communication Protocols**: RTUs use protocols like DNP3, Modbus, and SNMP to transmit data to the master control station.

- 🔋 **Power Source Flexibility**: RTUs are self-sufficient in terms of energy, using battery modules, accumulators with solar panels, or DC power supplies.

- 💾 **Memory and Storage**: RTUs often have a CPU with memory capacity and may support SD cards for additional storage.

- 🔩 **Components**: Main components of an RTU include power source, CPU, discrete inputs, analog inputs, control relay outputs, and communication interface.

- 🏭 **RTU vs PLC**: RTUs are designed for harsh environments and long-distance outdoor locations, whereas PLCs are ideal for managing local areas like production lines.

- 🌡️ **Environmental Tolerance**: RTUs have rugged construction to operate reliably in extreme temperatures and conditions.

- 💰 **Cost and Size**: RTUs are typically larger and more expensive than PLCs due to their robust design and higher input/output capacity.

- ⚡ **Power Consumption**: RTUs consume less power than PLCs and can operate autonomously during power outages using backup power sources.

- 🛠️ **Customization**: RTUs can be customized and expanded with various circuit cards to perform specific functions.

- 💻 **Ease of Programming**: RTUs are easier to configure than PLCs, requiring no programming from scratch and can be managed through a web interface.

Q & A

What is an RTU and what is it used for?

-An RTU (Remote Terminal Unit) is a rugged, standalone microprocessor-based electronic control device used in industrial environments to monitor and control remote measuring stations that are geographically dispersed and often have no connection to the electricity grid or wired networks.

How does an RTU differ from a PLC?

-RTUs are designed for long-distance outdoor locations that are difficult to access, while PLCs (Programmable Logic Controllers) are ideal for managing local areas like production lines and plants. RTUs are more tolerant to harsh environments and typically have more IOs than PLCs.

What are the main components of an RTU?

-The main components of an RTU include the power source, central processing unit (CPU), discrete inputs, analog inputs, control relay outputs, and communication interface.

How does an RTU ensure reliable monitoring of field equipment?

-An RTU gathers and collects data from connected sensors, performs data processing on the aggregated data, and translates the raw data into a transmittable format. It also reports issues immediately when measured values fall below or exceed predefined thresholds.

What kind of power source does an RTU use?

-RTUs are self-sufficient in terms of energy, using a battery module or an accumulator with a solar panel. They can also use a DC standard power supply as a primary power source, converting AC input voltage to DC output voltage.

How does an RTU communicate with a master control station?

-RTUs establish interfaces between field instruments and the automation control system via a communication network, using either a secure wireless network or cables connected to communication channel interfaces in a wired network. They use protocols such as DNP3, Modbus, and SNMP to transmit status data.

What is the purpose of the CPU in an RTU?

-The CPU, or central processing unit, is the system brain of an RTU. It runs the processing of the primary function and commonly employs a 16-bit or 32-bit microprocessor with a memory capacity of 256 kilobytes.

How does an RTU handle power source failures?

-In the event of power source failure, RTUs can still operate autonomously due to flexible and freely combinable power supply options, such as redundant and backup battery modules, accumulators with solar panels, or DC power sources with battery backup.

What are the environmental tolerances of an RTU?

-RTUs have a rugged construction and are designed to operate reliably in environments with extreme temperatures, relative humidity of non-condensing, and withstand power surges, as well as protection against vibration, dust, rain, and fog.

How do RTUs and PLCs differ in terms of programming?

-RTUs have built-in capabilities that can be configured easily through a web interface without additional software, while PLCs require specific software and programming skills in different PLC programming languages to write codes for any functions.

What are some of the advantages of using RTUs over PLCs in certain situations?

-RTUs are advantageous in situations where reliable data acquisition is critical and challenging, such as in long-distance outdoor locations that are difficult to access. They also consume less power due to energy-saving measures and can have autonomous operation even in power source failures.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)