Aula: Impressão 3D: aplicações industriais da manufatura aditiva

Summary

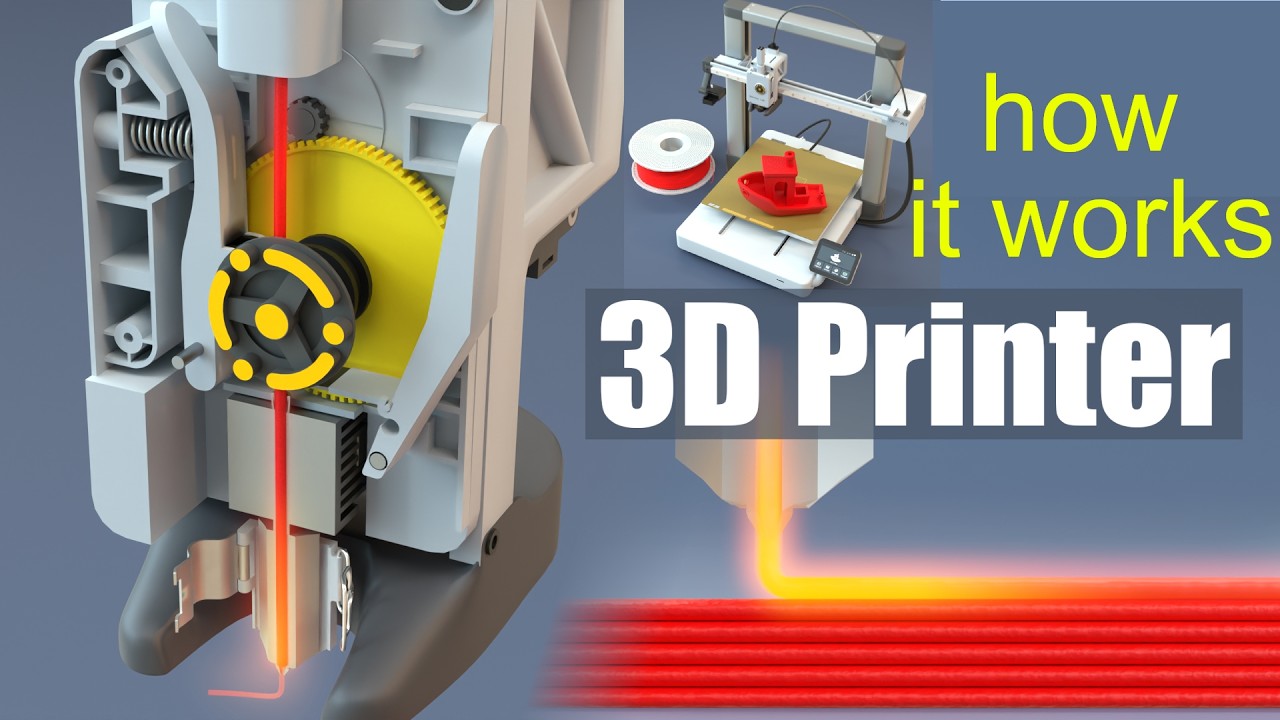

TLDRThis video introduces the fascinating world of 3D printing, also known as additive manufacturing, exploring its industrial applications and global impact. The presenter highlights the use of over 200 materials in 3D printing, emphasizing its potential for creating lightweight, efficient components, such as in aerospace. The video discusses the advantages of rapid prototyping, mass customization, and localized production, with industries like automotive and medical benefiting greatly. It underscores the economic potential of 3D printing, showcasing cost savings in manufacturing and the growing role of 3D printers in various sectors. The video encourages viewers to engage with upcoming content and stay informed about the transformative possibilities of 3D technology.

Takeaways

- 😀 3D printing, also known as additive manufacturing, is capable of producing objects using over 200 different materials, not just plastics.

- 😀 One of the main challenges in 3D printing is developing technology that can combine different materials in a single project.

- 😀 3D printing technologies vary depending on the material and type of product being produced, making it essential to choose the right approach for each application.

- 😀 In aerospace, 3D printing can significantly reduce the weight of components. For example, an 800g aircraft part can be reduced to just 310g, saving thousands in fuel costs over its lifetime.

- 😀 By printing parts with reduced weight, significant operational savings can be achieved over the lifecycle of an aircraft. For instance, a weight reduction of 490g could save $45,000 in fuel costs over 30 years.

- 😀 While the upfront cost of producing parts with 3D printing may be higher, the return on investment (ROI) can be substantial due to long-term savings and efficiency improvements.

- 😀 3D printing accelerates the design and testing process by enabling rapid prototyping and allowing quick changes to designs based on consumer feedback.

- 😀 Industries such as aerospace, automotive, and healthcare are increasingly adopting 3D printing for custom parts, prototypes, and low-volume production, offering flexibility and speed.

- 😀 3D printing can drastically shorten lead times, enabling quicker market entry and reducing the need for traditional manufacturing molds.

- 😀 Mass customization is a key advantage of 3D printing, allowing for high-volume production of tailored products without the need for large-scale manufacturing processes or molds.

- 😀 The future of 3D printing includes the potential to create locally produced custom parts, eliminating the need for large inventories and reducing supply chain complexities.

Q & A

What is 3D printing also known as?

-3D printing is also known as additive manufacturing.

What are some examples of materials that can be used in 3D printing?

-There are more than 200 materials that can be used in 3D printing, including plastics, metals, ceramics, and even cement for construction purposes.

What is the main challenge in the current 3D printing technology?

-The biggest challenge is developing technologies that can combine different materials in a single project.

How can 3D printing impact the weight and cost of aircraft parts?

-By reducing the weight of parts, such as a 800g piece of an aircraft, to as low as 310g, it can save significant amounts in fuel costs. Over the lifetime of an aircraft, a single lighter part can save up to $45,000.

What is the economic advantage of producing a 3D printed part with a higher initial cost?

-Although the initial cost of a 3D printed part may be higher, it can lead to long-term savings. For example, a part costing $2,500 to produce may save $9,000 over its lifetime due to reduced fuel consumption.

What are some of the primary applications of 3D printing in industry?

-3D printing is primarily used for rapid prototyping, creating test models, and proving concepts. It is also used for manufacturing tools and molds, and it has potential in mass customization and low-volume production.

What does 'mass customization' mean in the context of 3D printing?

-Mass customization refers to producing customized products on a large scale. 3D printing allows for this by enabling rapid design changes and eliminating the need for traditional manufacturing molds.

How can 3D printing impact the automotive and aerospace industries?

-In the automotive and aerospace industries, 3D printing allows for the production of lightweight, customized parts with improved mechanical properties, such as energy absorption and heat dissipation.

What is the role of 3D printing in reducing lead times and inventory costs?

-3D printing can drastically reduce lead times by producing parts locally and on-demand, eliminating the need for large inventories and reducing logistics costs.

How has the 3D printing industry evolved in recent years?

-The 3D printing industry has seen significant growth, particularly in industries like medical, aerospace, and automotive. Companies like BMW and Audi have begun producing millions of parts using 3D printing technology.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

3D Printers - CompTIA A+ 220-1101 - 3.7

How Things Are Made | An Animated Introduction to Manufacturing Processes

An Introduction to Additive Manufacturing/3D Printing

How does a 3D Printer work? (A1 by Bambu Lab)

What is 3D printing?

How 3D printing is enabling the ‘4th Industrial Revolution’ | Dr. Tim Minshall | TEDxOxBridge

5.0 / 5 (0 votes)