Electroplating - Easy DIY Nickel, Copper, Zinc Plating

Summary

TLDRThis video guides viewers through the simple process of electroplating at home using easily accessible materials. It covers the preparation of a nickel, copper, or zinc electrolyte solution, cleaning and prepping parts for plating, and demonstrates the electroplating process itself. With just a power supply, vinegar, salt, and a few basic tools, hobbyists can plate metal objects with nickel, copper, or zinc. The video emphasizes the simplicity and accessibility of electroplating, making it easy for beginners to experiment with metal finishing techniques.

Takeaways

- 😀 Nickel electroplating is simple and can be done with basic household materials like vinegar, salt, and a power supply.

- 😀 You can use an old phone charger or a small power supply that outputs less than 1 amp for the plating process.

- 😀 Nickel can be sourced from eBay by searching for 'nickel anode' to use as the plating material.

- 😀 Salt is added to the solution to increase the conductivity of the liquid, not for plating purposes.

- 😀 You can electroplate different metals like copper, zinc, and nickel by adjusting the solution and process accordingly.

- 😀 It's essential to clean the parts thoroughly before plating. Rusty parts require a more detailed cleaning process.

- 😀 The use of hydrochloric acid before plating helps etch the surface, providing a better bonding surface for the electroplated layer.

- 😀 The electrolyte solution turns green when the nickel electrolyte is ready, typically taking 1-2 hours depending on the power supply.

- 😀 For plating to be successful, the part should not have water beads on it; this indicates it is not clean enough to plate.

- 😀 Plating times can vary: for quick plating, about 20 minutes works, but for better results, aim for 45 minutes or more.

- 😀 If plating onto steel, it must first be plated with nickel before any other metal, as copper won't directly plate onto steel.

Q & A

What is the basic equipment required for nickel electroplating?

-The basic equipment required for nickel electroplating includes a container, a small power supply (like an old phone charger or batteries), vinegar, salt, and a piece of metal to plate, such as nickel.

Why is salt added to the electroplating solution?

-Salt is added to the electroplating solution to increase the conductivity of the liquid, which helps the electroplating process by improving the flow of electricity.

How can you determine the polarity of your power supply?

-You can determine the polarity of your power supply by observing where the bubbles form in the electrolyte. The side with bubbles is the negative terminal.

What should the color of the nickel electrolyte be after a couple of hours?

-After a couple of hours, the nickel electrolyte should turn a green color, resembling watery Gatorade. This indicates that the nickel electrolyte has been successfully created.

What is the purpose of using hydrochloric acid before electroplating?

-Hydrochloric acid is used to etch and clean the part before electroplating. It ensures that the part is free from oils or grease, which could prevent proper plating.

Why is it necessary to ensure that parts are immaculately clean before plating?

-Parts must be immaculately clean and grease-free because any contamination can prevent proper plating. If water beads up on the part, it will not plate correctly.

Can electroplating be done on steel directly with copper or zinc?

-No, electroplating cannot be done directly on steel with copper or zinc. Steel must first be plated with nickel, and then copper or zinc can be plated onto the nickel layer.

What happens if you don't plate the parts long enough?

-If you don't plate the parts long enough, the plating will be thin and may not provide sufficient coverage or durability. For example, with copper, plating for too short a time could result in the copper wearing off quickly.

What is the effect of using a brightener in the electroplating process?

-Using a brightener in the electroplating process results in a shiny, smooth finish on the plated part. Without brighteners, the plated metal (like zinc) may appear dull and uneven.

How do you ensure the electroplated metal is evenly distributed on the part?

-To ensure even plating, you should rotate the part periodically during the electroplating process. This helps the solution to coat the part evenly from all sides.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

begini cara menanam bawang merah dari awal sampai panen tanpa pupuk

Membuat Aquaponik Sederhana dengan Kolam Terpal Easy Grow

Cara membuat kompos dari batang pisang yang kaya manfaat sebagai penyubur tanaman

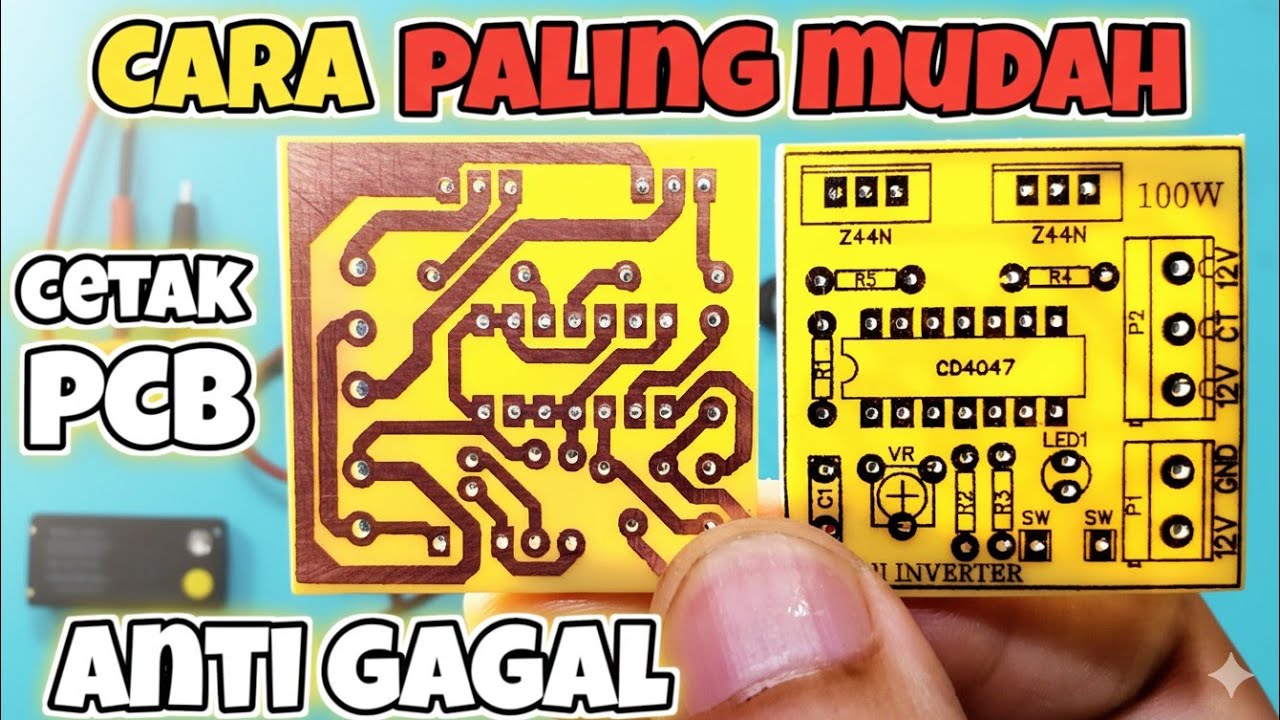

CARA CETAK PCB MANUAL Paling mudah anti gagal

KENAPA GAK KEPIKIRAN BUAT ALAT INI DARI DULU !!!

How to make Custom Holographic Trading Cards using Cricut Explore 3

5.0 / 5 (0 votes)