BMS Monitoring & Control of AHU Components and Sensors

Summary

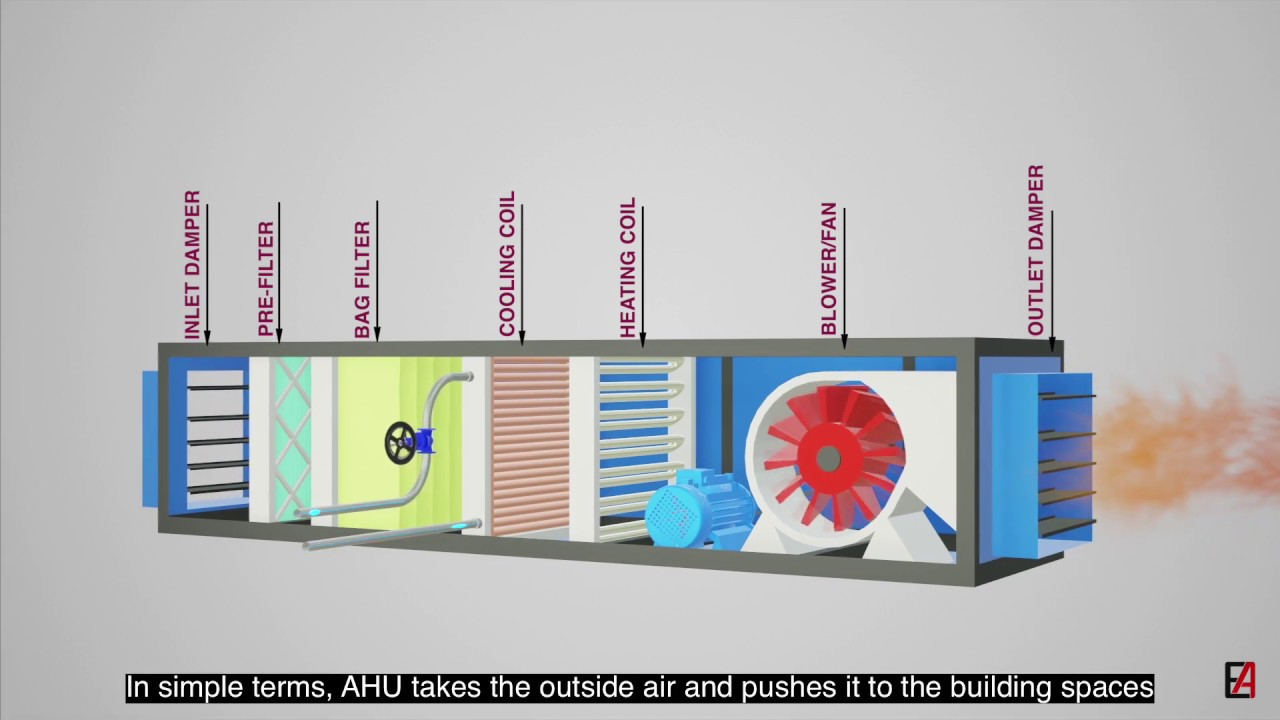

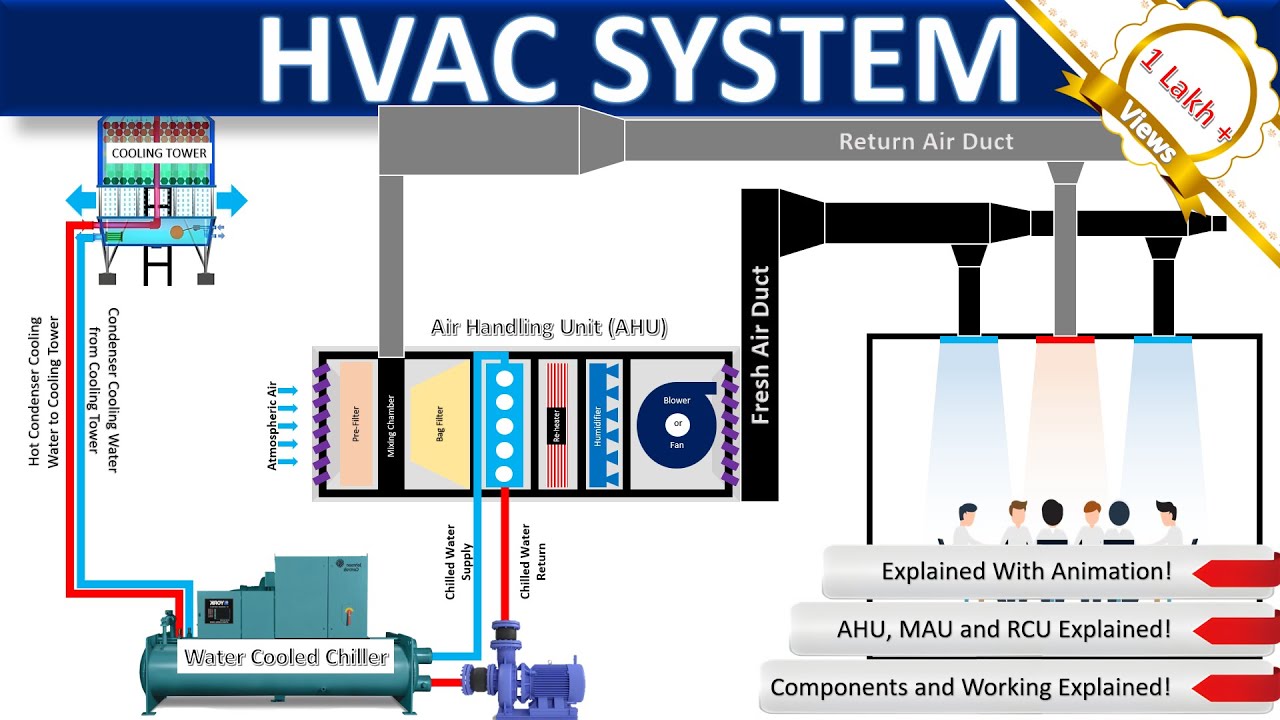

TLDRIn this video, we explore the BMS monitoring and control of Air Handling Units (AHUs), focusing on key components like dampers, filters, fans, and chilled water systems. Using a simple AHU as an example, the video explains how motorized actuators, differential pressure switches, and control valves are utilized to maintain optimal performance. Sensors for temperature, humidity, CO2, and chilled water are also discussed in detail, highlighting their importance in maintaining efficiency. Viewers will gain insights into BMS integration and its role in ensuring proper AHU operation, with future videos covering more complex AHU setups.

Takeaways

- 😀 Air Handling Units (AHUs) are critical in HVAC systems, with BMS monitoring and control enhancing their efficiency.

- 😀 BMS monitoring allows for precise control of AHU components such as dampers, filters, fans, and cooling coils.

- 😀 Actuators on dampers come in two types: Open/Close and Modulating, with modulating actuators offering finer control.

- 😀 Differential pressure switches monitor the cleanliness of filters and fans, triggering alarms when maintenance is needed.

- 😀 Chilled water flow through the cooling coil is controlled by actuators, which can be either Open/Close or modulating for precision control.

- 😀 Sensors used in AHUs include duct temperature, humidity, CO2, and water temperature sensors, critical for accurate system control.

- 😀 The Fresh Air Duct Temperature & Humidity Sensor monitors the air quality before conditioning, ensuring efficient cooling.

- 😀 Monitoring the temperature difference across filters helps detect clogging and prevent reduced airflow, ensuring optimal performance.

- 😀 The BMS controls the cooling coil’s temperature based on chilled water flow, ensuring proper comfort levels in the building.

- 😀 The video introduces a basic AHU schematic to help viewers understand sensor placement and the components involved in BMS monitoring.

Q & A

What is the main purpose of BMS monitoring and controls for an AHU?

-The main purpose of BMS monitoring and controls for an AHU is to regulate and monitor various components like dampers, filters, fans, and chilled water systems. This ensures the optimal performance and efficiency of the AHU while maintaining comfort for building occupants.

What are the two types of actuators used for damper control in AHUs?

-The two types of actuators used for damper control are Open/Close Actuators and Modulating Actuators. Open/Close actuators operate in only two positions (fully open or fully closed), while modulating actuators allow for variable positioning from 0 to 100%.

Why are differential pressure (DP) switches used in AHUs?

-DP switches are used in AHUs to monitor the pressure difference across filters and fans. This helps detect when filters are clogged, indicating that cleaning is needed, and ensures airflow is maintained through the fan. They also aid in detecting belt failures in belt-driven fans.

What does a modulating actuator provide that an open/close actuator does not?

-A modulating actuator provides precision control by adjusting the valve or damper position anywhere from 0 to 100%, allowing for more fine-tuned regulation. In contrast, an open/close actuator only allows for two positions: fully open or fully closed.

How do chilled water control valves affect the AHU's cooling performance?

-Chilled water control valves regulate the amount of chilled water passing through the cooling coil, which directly affects the cooling performance of the AHU. By controlling the flow of chilled water, these valves help maintain the desired temperature within the building.

What types of signals are used for controlling modulating actuators in AHUs?

-Modulating actuators in AHUs use analog signals for control, including Analog Input and Analog Output signals. These allow for continuous adjustment between fully closed and fully open positions, providing more precise control.

What sensors are typically used to monitor air quality and temperature in an AHU?

-Typical sensors used in AHUs include duct temperature sensors, duct humidity sensors, and CO2 or air quality sensors. These sensors help monitor the air quality and temperature at various points in the air handling process.

What role do the temperature sensors in the chilled water lines play in the AHU system?

-The temperature sensors in the chilled water lines monitor the temperature of the chilled water entering and exiting the cooling coil. This data is crucial for controlling the amount of chilled water required to maintain the desired cooling performance.

How do the fresh air duct temperature and humidity sensors contribute to the AHU system?

-The fresh air duct temperature and humidity sensors monitor the air entering the AHU before it is conditioned. This helps ensure that the AHU is properly adjusting the air conditions, such as temperature and humidity, to maintain optimal indoor comfort.

Why is it important to have both supply and return temperature sensors in an AHU system?

-Having both supply and return temperature sensors allows the system to monitor the efficiency of the cooling process. The supply sensor tracks the temperature of air being supplied to the building, while the return sensor monitors the temperature of air leaving the building, helping adjust the cooling performance as needed.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Air Handling Unit (AHU) Fundamentals with Cooling Principle and its components

Penjelasan Tentang instalasi AHU accsesoris

Central air conditioning system working Animation

HVAC Systems : Understanding Components and Functionality | Mr. Smart Explains!

HVAC Training - Basics of HVAC

FAMILIARIZATION OF ENGINE CONTROL CONSOLE | Electrician leckyjake

5.0 / 5 (0 votes)