Central air conditioning system working Animation

Summary

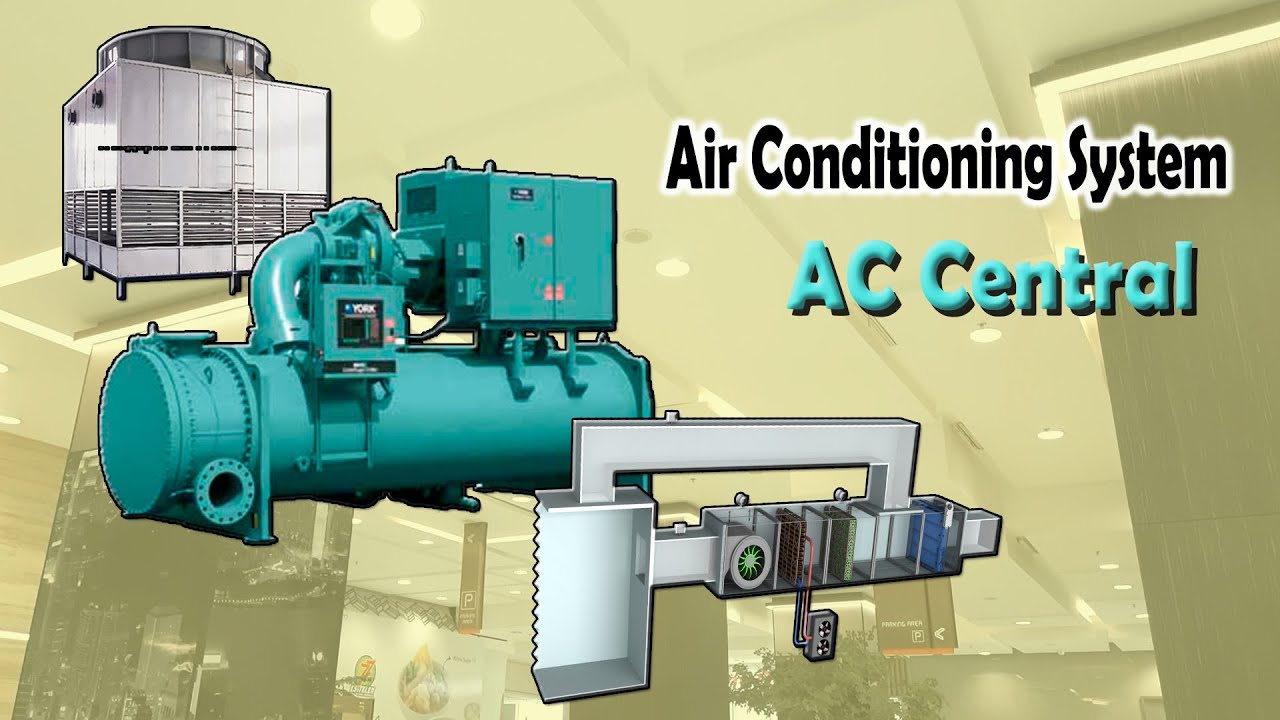

TLDRThe video explains the centralized air conditioning system, commonly used in commercial buildings for large-scale cooling. It outlines the three main cycles: refrigerant, chilled water, and condenser water cycles, detailing their components and processes. The refrigerant cycle involves the compressor, condenser, expansion valve, and evaporator, while the chilled water cycle focuses on air handling units and water pumps. The condenser water cycle is explained through cooling towers and pumps, emphasizing how heat transfer occurs efficiently in each stage. This overview helps students understand the functioning of centralized air conditioning systems.

Takeaways

- ❄️ The centralized air conditioning system is typically used for large cooling capacities, commonly in commercial settings.

- 🔄 The system comprises three main cycles: refrigerant cycle, chilled water cycle, and condenser water cycle.

- 🔧 Key components in the refrigerant cycle include the compressor, condenser, filter dryer, expansion valve, and evaporator.

- ⚙️ The chilled water cycle primarily involves the air handling unit and water pump.

- 🌊 In the condenser water cycle, the cooling tower and water pump play crucial roles in the heat removal process.

- 🌀 The compressor increases refrigerant pressure and temperature to facilitate heat transfer in the condenser.

- 🌡️ The condenser removes heat from the refrigerant, condensing it from high-pressure gas to a high-pressure liquid.

- 💧 The expansion valve reduces refrigerant pressure and controls its flow into the evaporator, where it absorbs heat.

- 🌬️ In the air handling unit, chilled water cools the air by absorbing heat, with centrifugal pumps circulating the water.

- 🏗️ The cooling tower in the condenser water cycle cools down the water that absorbs heat from the refrigerant, ensuring continuous system function.

Q & A

What is the primary purpose of a centralized air conditioning system?

-A centralized air conditioning system is primarily used for large cooling capacity, typically for commercial purposes.

What are the three main cycles involved in a chiller system?

-The three main cycles in a chiller system are the refrigerant cycle, the chilled water cycle, and the condenser water cycle.

What are the components involved in the refrigerant cycle?

-The components involved in the refrigerant cycle are the compressor, condenser, filter dryer, expansion valve, and evaporator.

What is the function of the compressor in the refrigerant cycle?

-The compressor increases the pressure and temperature of the refrigerant, facilitating heat transfer in the condenser.

What type of compressor is commonly used in chiller systems?

-The type of compressor commonly used is the scroll compressor, which works based on the pressure difference between the suction and discharge lines.

How does the condenser contribute to the refrigerant cycle?

-The condenser eliminates heat from the high-pressure gas refrigerant to the condenser water through convection and conduction.

What is the role of the filter dryer in the refrigerant cycle?

-The filter dryer acts as a dirt filter and absorbs moisture, ensuring that the refrigerant is clean and dry before entering the expansion valve.

What is the purpose of the expansion valve in the refrigerant cycle?

-The expansion valve reduces the pressure and controls the flow of refrigerant entering the evaporator, causing a dramatic drop in temperature.

How does the evaporator interact with the chilled water cycle?

-The evaporator absorbs heat from the chilled water coming from the air handling unit, causing the refrigerant to evaporate into a low-pressure gas.

What are the components of the chilled water cycle?

-The components of the chilled water cycle are the air handling unit and the water pump.

What is the function of the cooling tower in the condenser water cycle?

-The cooling tower cools down the temperature of the condenser water, which is then used to absorb heat from the refrigerant at the condenser.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Reasons why you CANNOT use Peltier for air conditioning

Cara Kerja AC Central Dengan Water Cooled Chiller

HVAC Overview for Beginners | What is HVAC?

How To Make Infrared Cooling Paint (Electricity Free Air Conditioning)

How Engine Cooling System Works ? Cooling System Explained |Air Cooled | Oil Cooled | Liquid Cooled

HVAC Training - Basics of HVAC

5.0 / 5 (0 votes)