entenda os codigos dos insertos de metal duro

Summary

TLDRThis video explains the key aspects of tungsten carbide inserts, commonly referred to as 'vidia,' used in machining and construction. It delves into the codes and nomenclature that describe these tools, helping users decode the complex information found on product packaging. The video also highlights the different types of inserts, including those for specific materials like steel, stainless steel, and cast iron, and provides insights into their applications, materials, and durability. By understanding these details, users can make more informed decisions when purchasing inserts for their machining needs.

Takeaways

- 😀 Hard metal inserts, also known as 'pastilhas de metal duro' or 'vídia,' are widely used in machining, drilling, and other industrial applications.

- 😀 The term 'vídia' originated from the first company in Brazil that popularized this type of insert, making it a common name in the industry.

- 😀 The inserts are commonly used in drilling tools, civil construction, and oil drilling, with machining being their primary application.

- 😀 When purchasing inserts online, they often come with complex codes that represent key specifications like shape, angle, and material properties.

- 😀 The insert code (e.g., 'TN MG 16 04 04 R') indicates essential information such as the insert's shape (e.g., triangular), dimensions, and material suitability.

- 😀 Understanding the insert's code is crucial for selecting the right insert for specific tasks, as a mismatch can lead to poor performance or damage.

- 😀 Early hard metal inserts were designed to be welded onto supports, but modern versions often come with a coating to enhance their durability.

- 😀 Inserts without coatings may have a shorter lifespan, while coated inserts can last two to three times longer due to improved wear resistance.

- 😀 The insert's material designation, like 'P' for steel or 'M' for stainless steel, helps determine its ideal application for different materials.

- 😀 It's important to check the insert’s application code (e.g., 'P' for steel, 'M' for stainless steel) before purchasing to ensure it’s suitable for the material you are working with.

- 😀 The speaker encourages further research into hard metal inserts, as they are versatile tools that significantly enhance machining capabilities.

Q & A

What are the main applications of carbide inserts (pastilhas)?

-Carbide inserts are mainly used in machining, particularly for cutting, drilling, and milling. They are essential in processes involving metalworking, construction, and even oil extraction. Their primary application is in machining operations, but they are also used in drills, taps, and other industrial tools.

What does the term 'pastilha' refer to in the context of this script?

-'Pastilha' is the Portuguese word for insert, specifically referring to hard metal inserts, often made from tungsten carbide, that are used in cutting tools for machining and metalworking.

What does the code 'TN MG 1604 04 R' represent on an insert packaging?

-The code 'TN MG 1604 04 R' is a detailed specification of the insert's shape, size, thickness, and other characteristics. For example, 'TN' refers to the shape of the insert (which could be triangular), 'MG' indicates the material, '1604' refers to the size and thickness, and 'R' designates the radius of the insert.

Why is it important to understand the insert code when purchasing carbide inserts?

-Understanding the insert code is crucial because it helps identify the shape, size, material, and application of the insert. A wrong selection could lead to tools that do not fit or perform poorly, such as purchasing an insert that doesn't match the required hole diameter or cutting angle.

What is the significance of the shape designation in the insert code?

-The shape designation in the insert code indicates the geometry of the insert. For example, a triangular shape is indicated by a specific code, and each shape is optimized for particular applications in machining. There are various shapes, each suited to different cutting conditions.

What is the role of coatings on carbide inserts?

-Coatings on carbide inserts, such as a micro-thin layer, are applied to enhance their durability and performance. These coatings can significantly extend the lifespan of the insert, sometimes by two or three times, by improving wear resistance and maintaining cutting efficiency.

How do carbide inserts differ from their early counterparts, according to the video?

-Early carbide inserts were typically designed to be welded onto supports. However, modern inserts often come with specialized coatings for improved durability and can be fixed using a variety of other methods, such as screw-in mechanisms.

What does the code 'PM KNS H' represent in the context of insert usage?

-'PM KNS H' is a code that refers to the application type of the insert. For example, 'P' indicates that the insert is meant for use with steels and carbon steels, while 'M' would be for stainless steel, and 'K' could be used for cast iron. The final 'H' refers to its suitability for hardened metals.

Why is it important to select the correct application code when choosing an insert?

-Choosing the correct application code is vital because each insert is designed to handle specific materials. For instance, a carbide insert for stainless steel will not perform as effectively on carbon steel, and vice versa. Using the wrong insert could result in poor machining results or premature wear.

What are some of the common mistakes people make when purchasing carbide inserts online?

-A common mistake is purchasing inserts without understanding their application or specifications, such as buying an insert intended for one material but using it on another. Additionally, some online descriptions do not clearly indicate the application codes or intended uses, which can confuse those unfamiliar with the terminology.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Electrochemical Grinding Process | How electrochemical grinding works

Stationary Anode X-ray Tube (Part - 6)

Konstruksi Bangunan2_Konstruksi Kayu

WATER JET MACHINE PROCESS : Working of abrasive water Jet machining process (animation).

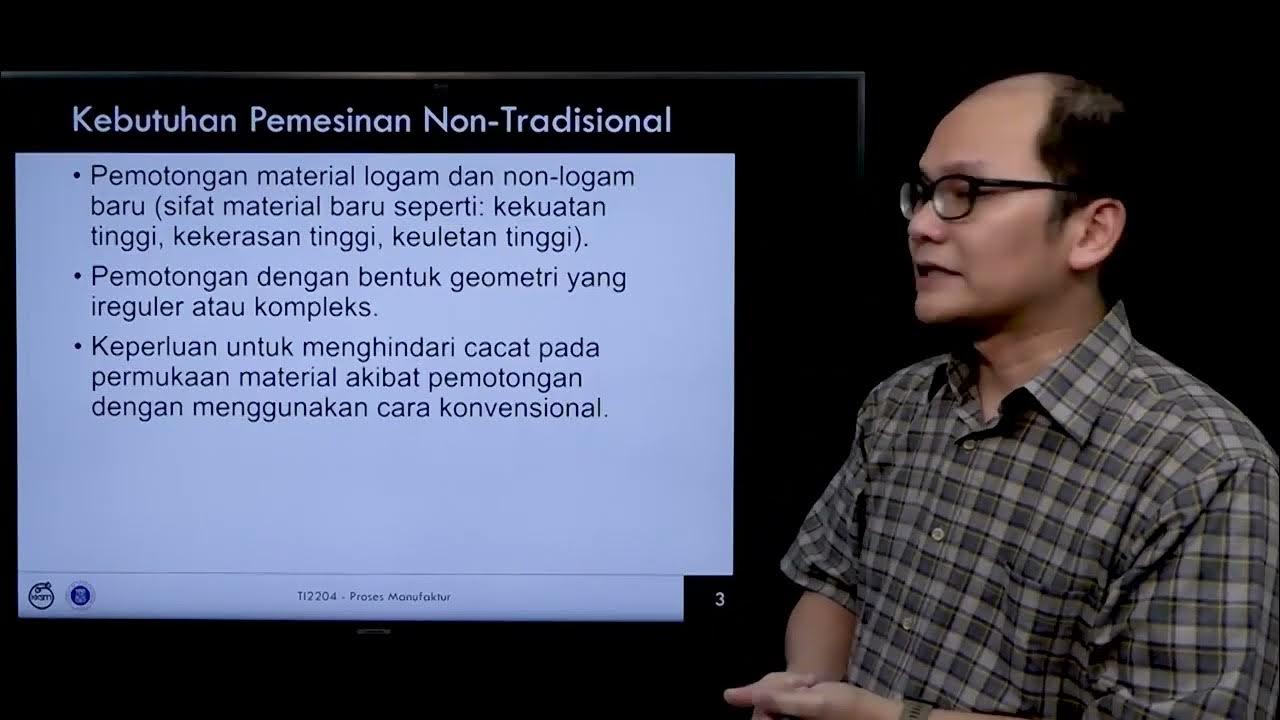

Proses Pemesinan Non Tradisional part 1

HOW BIC PENS are MADE 🖊️ | How Pen Ink is Made

5.0 / 5 (0 votes)