Guided Wave Radar Level Measurement - [Echo Curve Reading]

Summary

TLDRThis video explains guided wave radar (GWR) technology for level measurement in industrial applications, particularly in oil and gas. It covers how GWR works by emitting electromagnetic pulses along a probe, reflecting off the media to determine levels. The advantages include consistent measurement and superior interface detection, while disadvantages highlight cost and potential signal interference. The video also demonstrates how to interpret echo curves and troubleshoot common setup issues, emphasizing the importance of correct dielectric constant settings. Overall, it serves as a comprehensive guide for understanding and effectively utilizing GWR systems.

Takeaways

- 📏 Guided wave radar (GWR) is a modern level measurement instrument gaining popularity in oil and gas applications.

- ⚡ GWR operates by emitting high-frequency electromagnetic pulses along a probe, measuring the time it takes for the signals to return.

- 🌊 It can measure both level and interface levels, effectively distinguishing between fluids of different densities, like oil and water.

- 📊 The echo curve visually represents microwave reflection strength over time, aiding in the commissioning and fault-finding processes.

- 🔧 One major advantage of GWR is its consistent measurement capability despite fluctuations in temperature and pressure.

- 🔩 GWR has no moving parts, which reduces maintenance needs and overall lifetime costs compared to other technologies.

- ⚠️ However, initial costs for GWR can be high compared to simpler alternatives like pressure transmitters.

- 📈 Proper setup of dielectric constants is crucial, as incorrect settings can lead to false readings or ignored reflections.

- 🚫 Common setup issues include misconfigured thresholds that can cause false level indications or missed measurements.

- 🛠️ Utilizing features like an upper null zone can help mitigate false readings from unwanted reflections near the probe.

Q & A

What is Guided Wave Radar (GWR) primarily used for?

-Guided Wave Radar is primarily used for level measurement in various industries, particularly in oil and natural gas applications.

How does GWR measure the level of media in a vessel?

-GWR measures the level by emitting high-frequency electromagnetic pulses along a probe, which reflect off the media and return to the transmitter. The time difference between sending and receiving the pulses is used to calculate the distance to the media.

What is an interface level, and how can GWR measure it?

-An interface level occurs when two fluids of different densities, like oil and water, separate. GWR can measure this by detecting reflections from both the upper fluid level and the interface between the two fluids.

What are some advantages of using Guided Wave Radar?

-Advantages include consistent measurements despite pressure and temperature changes, minimal maintenance due to no moving parts, and superior interface measurement capabilities.

What are the disadvantages of GWR?

-Disadvantages include higher initial costs compared to simpler technologies, potential damage from moving products, and concerns about probe corrosion in volatile products.

What is an echo curve in the context of GWR?

-An echo curve is a graphical representation of the strength of microwave reflections over time, used to analyze the performance of the GWR during commissioning and troubleshooting.

Why is the dielectric constant important for GWR setup?

-The dielectric constant affects how electromagnetic waves are absorbed and reflected, determining the correct threshold for level readings and preventing false readings.

What issues can arise from incorrectly setting the dielectric constant?

-If set incorrectly, the threshold may be too high or too low, leading to the surface reflection being ignored or noise being detected as a false level reading.

What is the purpose of the upper null zone in GWR setup?

-The upper null zone is used to ignore reflections from a specified distance at the start of the probe, helping to prevent false level readings caused by noise or vessel structure reflections.

How can product condensation affect GWR readings?

-Product condensation can create unwanted reflections at the top of the probe, leading to false level indications, particularly in gas condensate systems.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

What is automatic tank gauging system?

💡 Radar vs. ultrasonic – what are the differences between the two measuring principles? | VEGA talk

Industrial Radar Sensors: Robust Sensing Principle under Extreme Environmental Conditions

The Differential Pressure Flow Measuring Principle (Orifice-Nozzle-Venturi)

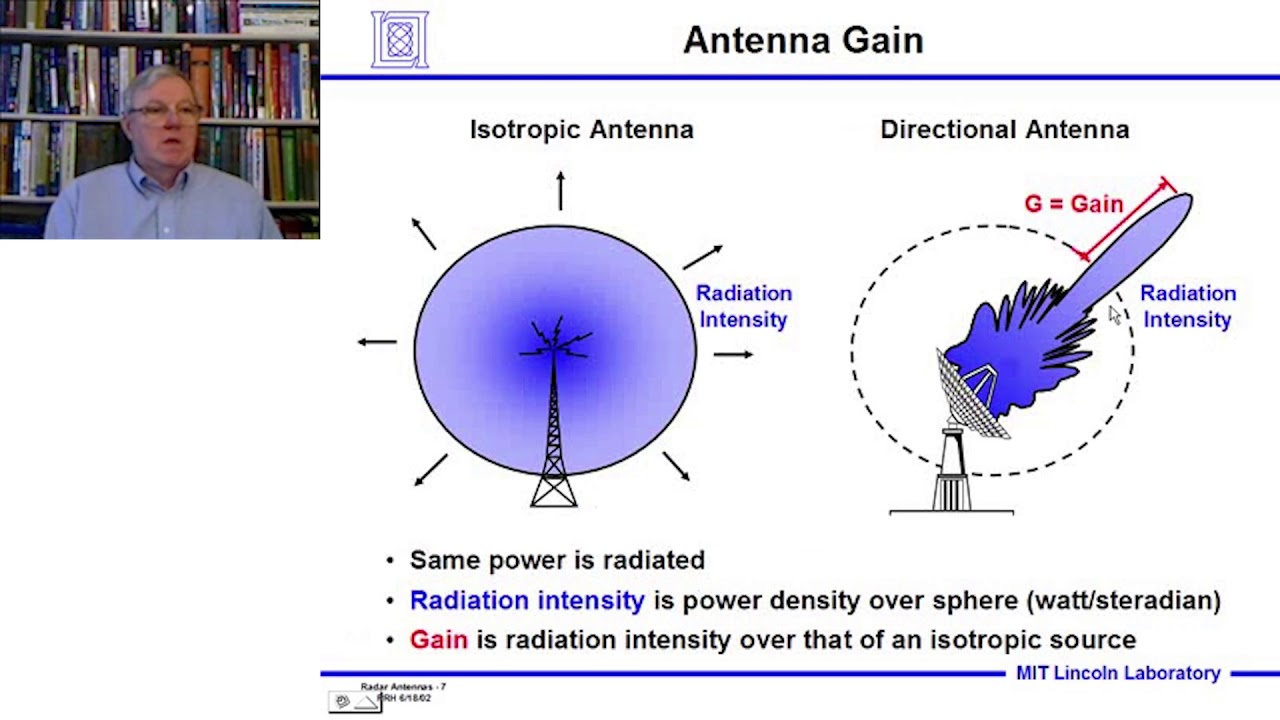

Introduction to Radar Systems – Lecture 6 – Radar Antennas; Part 1

Process control loop Basics - Instrumentation technician Course - Lesson 1

5.0 / 5 (0 votes)