SEM How To Series: Composite Adhesive & Repair

Summary

TLDRIn this video, Larry Trixler from Sim Products demonstrates the effective use of Fleet Line Composite Adhesive for repairing SMC and composite plastics. This fiber-enriched epoxy formula not only bonds but also eliminates common issues like swelling during painting. The repair process involves cleaning the damaged area, grinding edges, and applying a layered patch of fiberglass cloth and adhesive. With options for both air drying and heat curing, this product ensures strong, durable repairs. Trixler emphasizes the ease of use and versatility, making it a reliable choice for both bonding and repair in composite applications.

Takeaways

- 😀 The Fleet line composite adhesive is a fiber-enriched epoxy designed for bonding and repairing composite plastics like carbon fiber, SMC, and fiberglass.

- 😀 It has a working time of 35 minutes and a dry time of 3 hours, offering flexibility in the repair process.

- 😀 The product provides several heat set options: air drying, heating with a lamp at 180°F for 10 minutes, or using a heated paint booth at 140°F for 30 minutes.

- 😀 The fiber-enriched formula helps prevent swelling or haloing in the repair material after painting.

- 😀 The adhesive allows for bonding and repairing in one product, simplifying the repair process.

- 😀 Begin repairs by cleaning both sides of the damaged area with plastic and leather prep and using masking tape to prevent saturation.

- 😀 Grind away rough edges with a 36 grit disc, then sand the area with 80 grit paper, extending the repair zone 2-3 inches beyond the damage.

- 😀 Create a patch using fiberglass cloth sandwiched between layers of adhesive, ensuring it overlaps the damaged area by at least 1 inch.

- 😀 For front side repairs, construct a pyramid-shaped patch that matches the dished area size, using progressively smaller layers of cloth and adhesive.

- 😀 After the adhesive sets, sand the surface with 80 grit and then 180 grit, clean off the dust, and prime and refinish as per manufacturer's instructions.

Q & A

What is Fleet Line Composite Adhesive used for?

-It is used for bonding and repairing composite plastics such as carbon fiber, SMC, and fiberglass.

What is unique about the fiber enriched formula of this adhesive?

-The fiber enriched formula helps prevent swelling or haloing in the repair material after painting.

What are the drying options available for this adhesive?

-It can air dry for 3 hours or be accelerated with a heat lamp for 10 minutes at 180°F or in a heated paint booth for 30 minutes at 140°F.

What is the recommended grit for grinding away broken edges?

-A 36 grit grinding disc is recommended for this purpose.

How should the damaged area be prepared before applying the adhesive?

-The front and back sides should be cleaned with plastic and leather prep, and masking tape should be used to prevent saturation of exposed fibers.

What is the purpose of the fiberglass roller in the repair process?

-The fiberglass roller is used to seat the patch into the repair and to release air pockets.

How should the adhesive be mixed before application?

-The cartridge should be equalized by dispensing until both parts flow equally, and a test material should be dispensed to ensure proper mixing.

What is the procedure for constructing a patch for the repair?

-Create a patch using a layer of fiberglass cloth sandwiched between two layers of composite adhesive, ensuring it overlaps the damaged area by at least 1 inch.

What sanding steps should be taken after the repair has set?

-Sand the surface first with 80 grit, then with 180 grit sandpaper.

What should be done after sanding the repaired surface?

-Blow off the dust with clean dry compressed air and then prime and refinish according to the manufacturer's instructions.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Design Composite Pressure Vessel with Liner Using ANSYS ACP

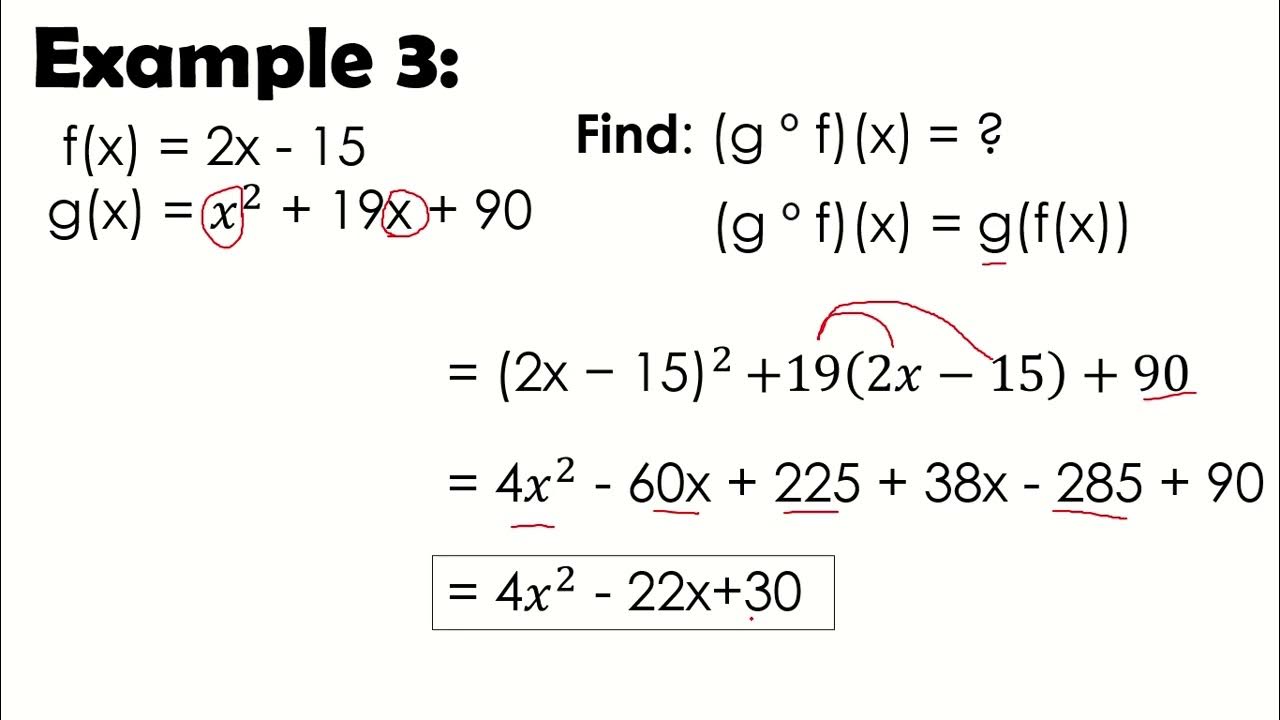

Composition of Function by Ma'am Ella Barrun

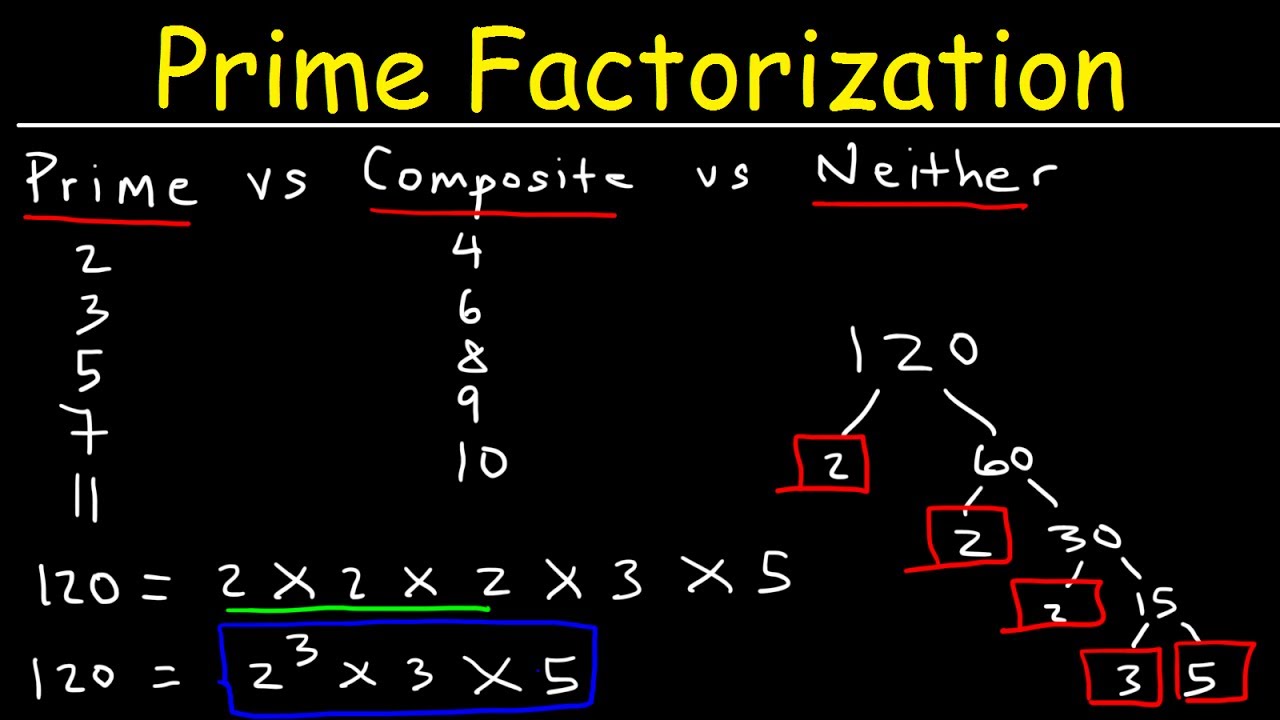

Prime Factorization Explained!

時空間合成【AfterEffects/アフターエフェクト チュートリアル】

How Mushrooms Are Turned Into Bacon And Styrofoam | World Wide Waste

Cara Pengambilan Sample (Sampling), SMK Farmasi Industri, PPMP, XI

5.0 / 5 (0 votes)