Difference between IM and WM Physical Inventory Process - SAP Best Videos

Summary

TLDRThis video outlines the key differences between Inventory Management (IM) and Warehouse Management (WM) physical inventory processes. It highlights how IM operates at the storage location level while WM functions at the storage bin level. The recounting process, stock postings, and movement types are compared, emphasizing the importance of accurate stock reconciliation to support sales and procurement planning. Effective physical inventory processes are crucial for aligning physical stock with system records, ultimately enhancing operational efficiency and customer service.

Takeaways

- 😀 IM (Inventory Management) handles stock at the storage location level, while WM (Warehouse Management) manages stock at the storage bin level.

- 📦 Stock counts in IM are performed at the storage location, whereas in WM, they are conducted at the storage bin level.

- 🚫 Both IM and WM allow for blocking postings to prevent any operations (like transfers or receiving) after creating a physical inventory document.

- 🔄 In IM, initiating a recount generates a new document number, while WM maintains the same document but creates versioned recounts.

- 📊 Stock postings in IM can be processed immediately upon entering the inventory count, regardless of differences.

- 🛑 In WM, stock postings must wait until differences are resolved using transaction LA20.

- 🔢 IM uses movement types such as 701 and 702, while WM employs movement types like 711 and 712 for physical inventory adjustments.

- 📝 Key transaction codes for IM include MA01, MA31, MA04, while WM transactions include LA01N, LX16, and LA21.

- ⚖️ The primary objective of both IM and WM is to reconcile system inventory with physical inventory to maintain accuracy.

- 📈 Accurate physical inventory helps avoid operational challenges, ensuring that sales and procurement teams can plan effectively.

Q & A

What are the primary focuses of Inventory Management (IM) and Warehouse Management (WM)?

-IM focuses on managing stock at the storage location level, while WM emphasizes stock management at the storage bin level.

How does the stock counting process differ between IM and WM?

-In IM, stock counts are performed at the storage location level, whereas in WM, counts are done at the storage bin level.

What happens when a physical inventory document is created in both IM and WM?

-The creation of a physical inventory document in both systems blocks stock postings to prevent any transactions during the counting process.

What is the recount process, and how does it differ between IM and WM?

-A recount is initiated if discrepancies are found. In IM, a new document number is generated for the recount, while in WM, the same document is used but with a versioning system.

Can stock postings occur immediately after entering inventory counts in IM?

-Yes, in IM, stock postings can be made immediately after entering the inventory count, regardless of discrepancies.

What must be done before stock postings can occur in WM after a physical inventory count?

-In WM, stock postings cannot occur until the differences are reconciled using specific transaction codes.

What are the typical transaction code prefixes for IM and WM?

-IM transaction codes typically start with 'M' (e.g., MA01, MA07), while WM transaction codes generally start with 'LA' (e.g., LA01N, LA20).

Why is it important to reconcile physical and system inventories?

-Accurate reconciliation is crucial for operational efficiency and customer satisfaction, as discrepancies can disrupt sales and procurement processes.

What challenges can arise from discrepancies between physical stock and system stock?

-Discrepancies can lead to issues such as the inability to fulfill sales orders, resulting in customer dissatisfaction and potential revenue loss.

What is the overall goal of both IM and WM physical inventory processes?

-The goal is to ensure that the physical inventory matches the system inventory, allowing for effective planning and operational management.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

What is Warehouse Management? [Intro to Inventory Management, Pick Pack Ship, WMS Software, etc]

FUNCIONES del ALMACÉN - Administración EFECTIVA de Almacenes y Control de Inventarios - Video 3

What is Inventory Management? | Inventory Types and Major Challenges | SafetyCulture

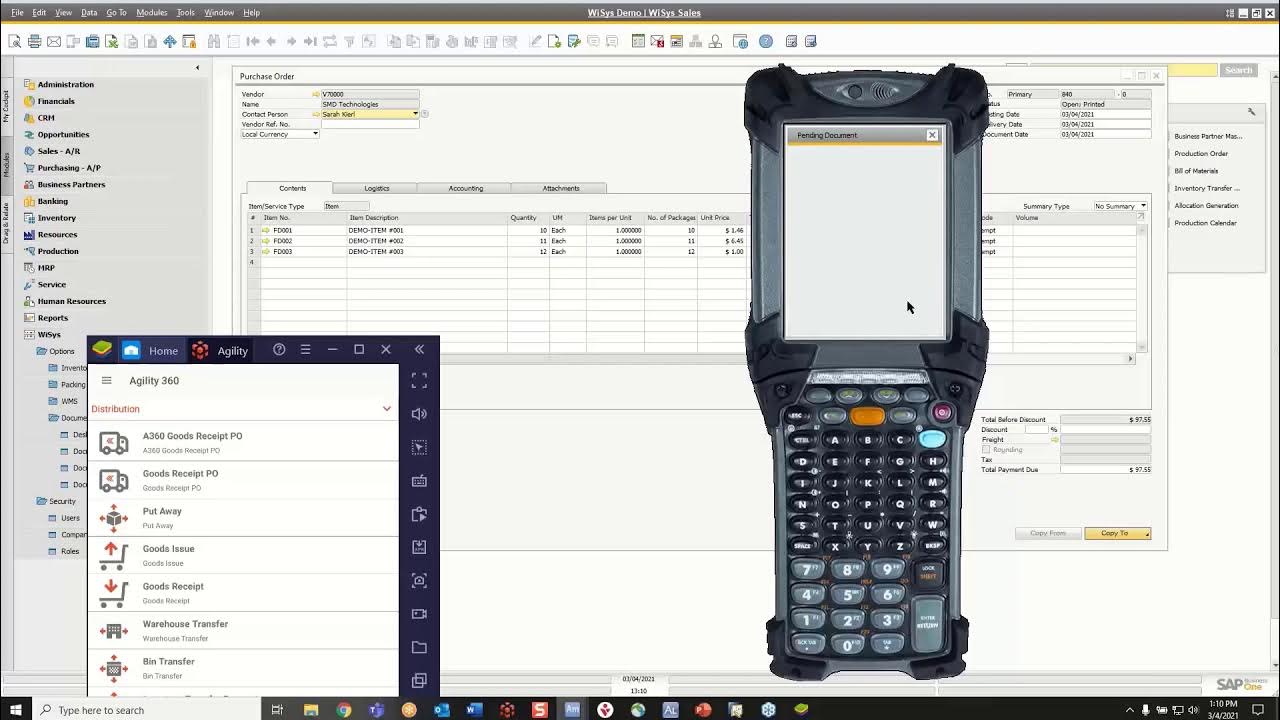

Introduction to WiSys Agility WMS for SAP Business One

RFID in Warehouse Environments with Zebra

Manajemen Persediaan (Inventory)

5.0 / 5 (0 votes)