DIAGRAMA DAP

Summary

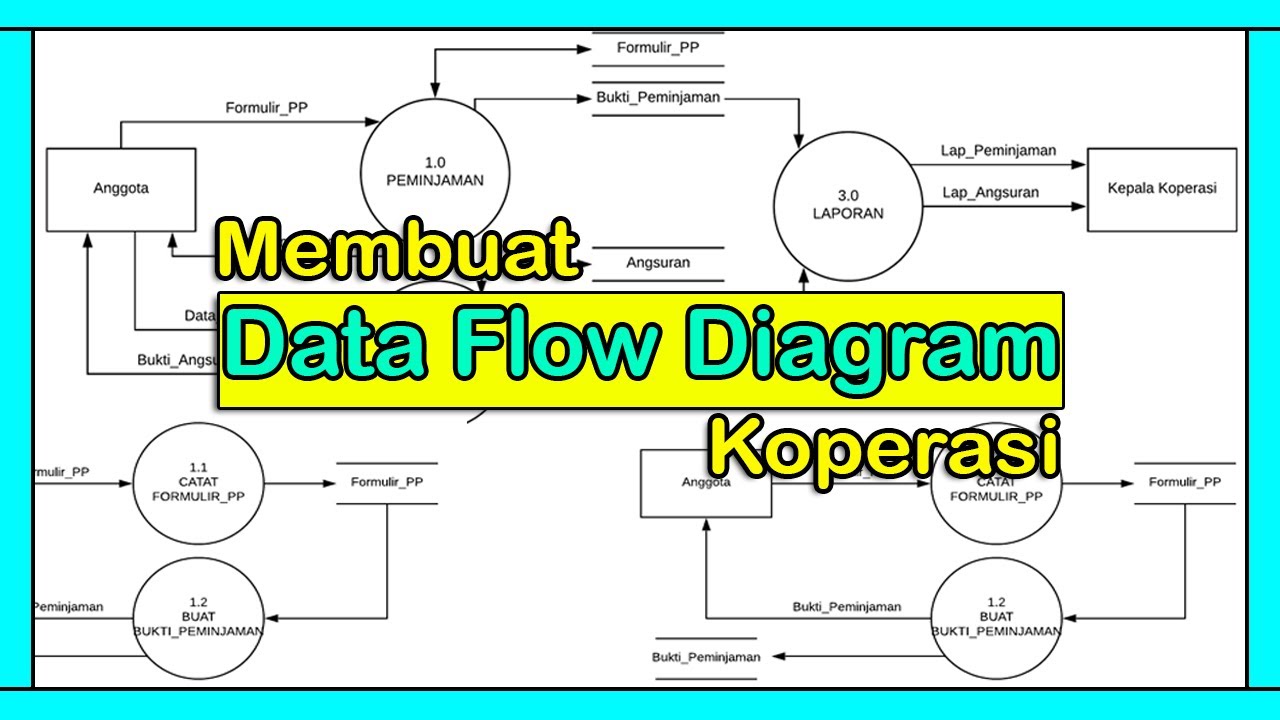

TLDRThis video explains the importance of the process activity diagram (DAP) for organizing and optimizing production processes. It covers how DAPs help identify inefficiencies, improve resource utilization, and eliminate unnecessary delays in manufacturing. The video also emphasizes the need for clear steps, from start to finish, to ensure a high-quality product. Key elements like tasks, control operations, delays, inspections, and storage are illustrated with symbols. It also highlights the role of employee training in improving productivity and reducing material waste, ensuring the production process runs smoothly and efficiently.

Takeaways

- 😀 A process activity diagram (DAP) is crucial for mapping out and improving processes step-by-step.

- 😀 DAP helps to visualize and improve efficiency by identifying unnecessary delays, resource wastage, and material inefficiencies.

- 😀 A DAP provides a detailed view of each stage in a process, from start to finish, helping to ensure optimal workflow.

- 😀 The key components of a DAP include tasks, operations, control operations, delays, storage, and decisions.

- 😀 DAP diagrams use specific symbols to represent different aspects, such as circles for operations, arrows for transport, and rectangles for inspections.

- 😀 The purpose of DAP is to improve productivity, reduce wastage, and optimize resource utilization in projects.

- 😀 A key benefit of using a DAP is identifying areas that need employee training, thus improving overall process quality.

- 😀 By visualizing the entire process, DAP helps in pinpointing flaws, increasing productivity, and enhancing quality control.

- 😀 Symbols like operations (circle), inspections (rectangle), and delays (D) provide a standardized way to represent each part of the process.

- 😀 DAP enables the identification of inefficiencies, helping to refine processes and ensure a smooth workflow, thus preventing the loss of materials and money.

Q & A

What is the purpose of creating a process activity diagram (DAP)?

-The purpose of creating a DAP is to provide an organized and detailed view of all the steps involved in a process, from start to finish. It helps identify and eliminate unnecessary delays, reduce material waste, and optimize resource usage.

How does a DAP help in identifying issues within a process?

-A DAP helps by providing a visual representation of each step in the process. This makes it easier to spot inefficiencies, delays, or issues in the workflow, which can then be addressed to improve the overall process.

What are the key components of a DAP?

-The key components of a DAP include tasks/activities, control operations, delays, storage, decisions, and deviations. These are represented using specific symbols to map the flow of the process.

What are the symbols used in a DAP, and what do they represent?

-In a DAP, different symbols represent various elements of the process. For example, a circle represents operations, a triangle represents storage, a rectangle represents inspections, a diamond represents decisions, and a square with a 'D' represents delays.

How does a DAP improve the efficiency of a project?

-By mapping out the process visually, a DAP highlights areas where time is wasted, resources are underutilized, or inefficiencies exist. This allows teams to address these issues, streamline operations, and ultimately improve the efficiency of the project.

How can a DAP help reduce material waste?

-A DAP helps identify points in the process where materials are being wasted. By optimizing the workflow and addressing these inefficiencies, waste can be minimized, ensuring resources are used more effectively.

What role does training play when using a DAP?

-Training plays a crucial role as it helps ensure that workers understand the process correctly and follow the steps as outlined in the DAP. Proper training can eliminate errors, reduce material waste, and improve overall process quality.

Why is it important to address delays in a process, and how does a DAP assist in this?

-Delays can significantly slow down production and affect the quality of the final product. A DAP assists by visually identifying where delays occur in the process, allowing teams to take action to resolve them and keep the process moving smoothly.

How are inspections represented in a DAP, and what is their significance?

-Inspections are represented by a rectangle in a DAP. They are significant because they ensure that the product meets the required quality standards before moving to the next step in the process.

What should be considered when filling out a DAP format in practice?

-When filling out a DAP format, it's important to include the description of activities, the sequence, the quantity of items being processed, the distance between activities, the time taken for each step, and the corresponding symbols. This helps in accurately mapping the process and identifying areas for improvement.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)