AAEON presents artificial intelligence - PCB Optical Inspection

Summary

TLDRThis video demonstrates an advanced AI-powered system used for defect detection in manufacturing lines. The system employs a rotating table and four cameras to scan boards for defects, with AI inference running on a NVIDIA TX 2060 and CUDA framework. Designed for electronics and board manufacturers, it reduces costs by eliminating the need for manual inspection. Additionally, it enhances efficiency by allowing for quick inspection adjustments without changing hardware. The solution can be customized and scaled with more cameras for faster inspection, and the technology can be demonstrated for potential customers.

Takeaways

- 🤖 The demonstration showcases an intelligent manufacturing setup using AI technology.

- 🛠️ A rotating table simulates a manufacturing line with boards being scanned by four cameras.

- 📸 The system detects defects in the manufacturing process using an AI inference application.

- 💻 The AI application runs on a system powered by an Nvidia TX 2060 and utilizes the CUDA framework.

- 🛡️ The goal is to detect defects without the need for human intervention.

- 🏭 Electronics and board manufacturers can benefit from this system by automating inspection tasks.

- 🔄 The system can support additional cameras to increase inspection efficiency.

- ⏩ This technology allows manufacturers to speed up their inspection processes and reduce costs.

- 💡 The system is adaptable, making it easy to change the object being inspected without altering the defect detection technique.

- 🏢 The company offers to demonstrate and assist in implementing this AI-powered inspection system for manufacturers.

Q & A

What is being demonstrated in the video?

-The video demonstrates an intelligent system using a rotating table to simulate a manufacturing line, where defects in manufacturing are detected by an AI inference application.

How does the defect detection system work?

-The system uses four cameras to scan words on the manufacturing line, and an AI inference application running on a Boxer system with an NVIDIA TX 2060 and CUDA framework detects any defects.

What hardware and software are used in the defect detection system?

-The system runs on a Boxer device equipped with an NVIDIA TX 2060 GPU and uses the CUDA framework for AI inference.

What is the primary benefit of using this AI-based defect detection system?

-The primary benefit is the ability to detect defects without human intervention, reducing the need for manual inspection and increasing inspection speed and efficiency.

Can the system be customized for different manufacturing setups?

-Yes, the system can be customized by adding more cameras and adjusting the inspection speed to fit different manufacturing lines.

How does the system help reduce costs in manufacturing?

-The system reduces costs by eliminating the need for manual inspection, saving time, and making it easier to switch between different objects for inspection.

What industries would benefit most from this system?

-Electronics and board manufacturers would benefit most from this system, as it can streamline inspection processes and reduce costs.

How many cameras are currently being used in the demonstration?

-The demonstration uses four cameras to scan the objects on the manufacturing line.

Is it possible to increase the number of cameras in the system?

-Yes, the system can accommodate more than four cameras, allowing for more detailed or faster inspections.

Can this system be demonstrated at other companies?

-Yes, companies can request a demonstration of the technology, and the developers can help build a similar system for their manufacturing needs.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Innovation Minute: How AI is Used in the Manufacturing Industry

Revolutionize Rail Track Monitoring with YOLO and Google Generative AI

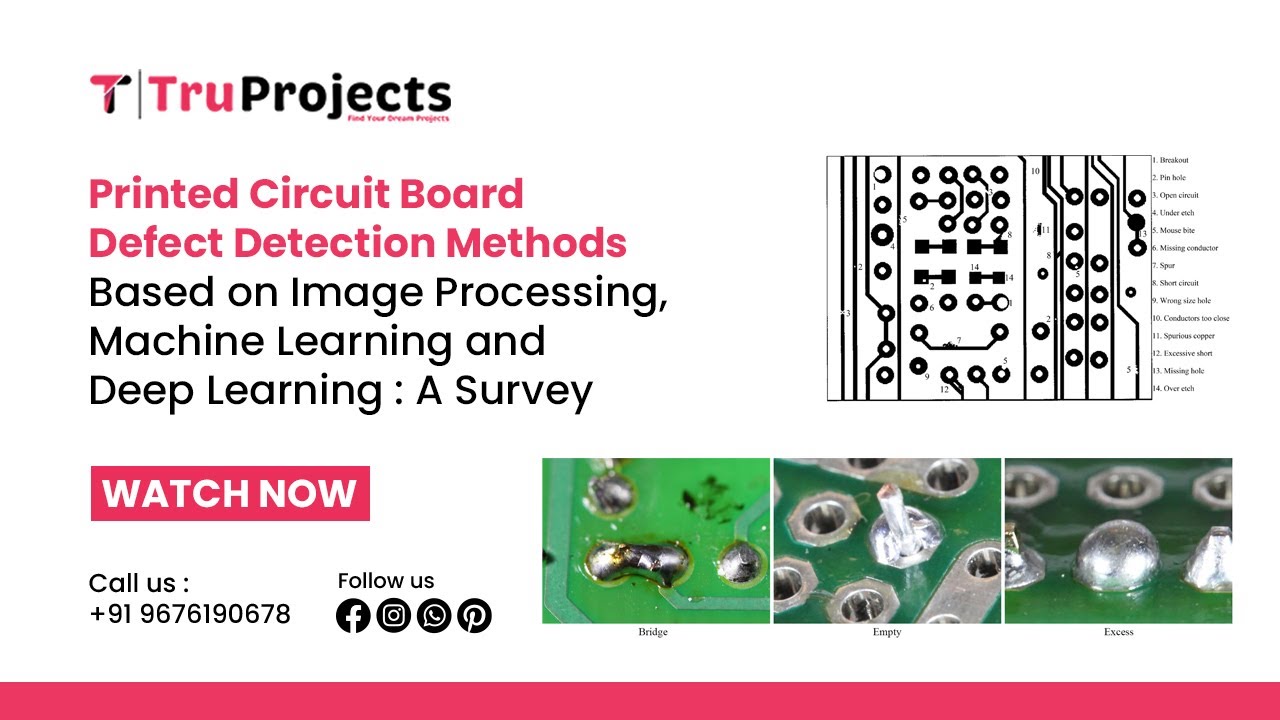

Printed Circuit Board Defect Detection Methods Based on Image Processing, Machine Learning and Deep

PENETRANT TESTING & MAGNETIC PARTICE LINSPECTION | POLITEKNIK NEGERI BATAM

5 "BORING" AI Automations To Sell For $1.5K+ Each in 2025

Heimdal DNS Security - Product Demo

5.0 / 5 (0 votes)