Producción industrial de mermelada de piña 🍍

Summary

TLDRThis transcript provides an in-depth look at the production process of pineapple jam, from the reception of raw materials to the final packaging. It covers key steps like washing, cutting, blending, and the importance of various quality control parameters such as temperature, pH, and Brix levels. The role of additives like citric acid, carboxymethyl cellulose (CMC), and potassium sorbate is explained, highlighting their impact on flavor, texture, and preservation. The importance of hygiene and precision in the process is emphasized, along with the regulatory bodies overseeing food safety.

Takeaways

- 😀 Industrial process flow diagrams represent the stages in transforming raw materials into finished products, such as pineapple jam production.

- 😀 The pineapple jam production process involves several stages, including raw material reception, selection, washing, and pulping.

- 😀 During the pineapple jam production, quality control is crucial and includes parameters like temperature, pH, and Brix degrees to ensure product consistency.

- 😀 The pineapple jam production flow includes stages like precooking, mixing with ingredients such as citric acid, pectin, and potassium sorbate, and finally vacuum sealing.

- 😀 Quality control equipment for pineapple jam includes thermometers, refractometers, and pH meters to monitor temperature, sugar content, and acidity.

- 😀 Temperature plays a key role in the industrial process by affecting the product's quality and production efficiency. Accurate temperature control ensures minimal waste and high-quality products.

- 😀 Brix degrees measure the sugar content in liquids, and in pineapple jam production, the ideal Brix level is around 65 for a high-quality jam.

- 😀 pH levels are critical in food production as they determine the acidity or alkalinity of the product. For pineapple jam, the pH should range between 3.1 to 3.5 for proper preservation.

- 😀 Ingredients like carboxymethyl cellulose (CMC), citric acid, and potassium sorbate are used to modify the texture, acidity, and shelf life of pineapple jam.

- 😀 In the pineapple jam production process, important calculations include dilution ratios for disinfecting fruits and containers, as well as material balance to determine mass losses during evaporation.

- 😀 The final step in the production process is the sealing of the pineapple jam in sterilized jars, ensuring that the product remains safe for consumption and extends its shelf life.

Q & A

What is the purpose of a flowchart in industrial processes?

-A flowchart in industrial processes is a graphical representation that visually outlines the steps and stages of an industrial process, showing how raw materials are converted into a final product, often in large quantities and aimed at a specific target audience.

What are the primary stages in the tamarind pulp extraction process?

-The primary stages in the tamarind pulp extraction process are weighing, selection, mixing, resting, and finally, the extraction of pulp.

What parameters are important for quality control in pineapple jam production?

-The key parameters for quality control in pineapple jam production include Brix degrees, pH level, and temperature, which must all be measured with specific tools to ensure product quality.

What is the significance of selecting fresh, ripe fruit in the jam production process?

-Selecting fresh and ripe fruit is crucial for ensuring the quality of the final jam product, as it helps achieve the desired flavor, texture, and overall product quality. Overripe or spoiled fruit should be avoided.

How does the scalding process affect the pineapple during jam production?

-Scalding, or precooking, involves immersing the pineapple in water at 100°C to destroy pectinolytic enzymes, which helps maintain the fruit's pectin content that is essential for the jam's texture.

Why is temperature control essential in industrial food production?

-Temperature control is vital because it directly impacts productivity, product quality, and minimizes waste. Precise temperature management ensures optimal processing and consistency in food products.

What does Brix measure, and why is it important in jam production?

-Brix is a unit of measurement for the concentration of dissolved solids, primarily sugars, in a liquid. In jam production, monitoring Brix ensures the right amount of sweetness and consistency, with 65 degrees Brix being ideal for pineapple jam.

How is pH measured, and why is it crucial for food safety in jam production?

-pH is measured using a pH meter or pH indicator strips, and it is important because it determines the acidity or alkalinity of a product. In jam production, maintaining the right pH (3.1 to 3.5 for pineapple jam) ensures food safety by inhibiting microbial growth.

What is the role of Carboxymethyl Cellulose (CMC) in jam production?

-CMC serves as a thickening agent in pineapple jam production. It helps achieve the desired consistency and texture by stabilizing the mixture and preventing clumping.

How is sodium hypochlorite used in the washing process during jam production?

-Sodium hypochlorite is used in the washing process at a concentration of 50 parts per million to disinfect the pineapple. The solution is applied for 10 minutes to ensure the removal of contaminants and maintain hygiene in the production process.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Like Ice Cream! Process of Making Makeup Cushion Foundation. Cosmetic Factory in Korea

How Modern Factory Producing Crystal Sugar Efficiently?

Matches | How It's Made

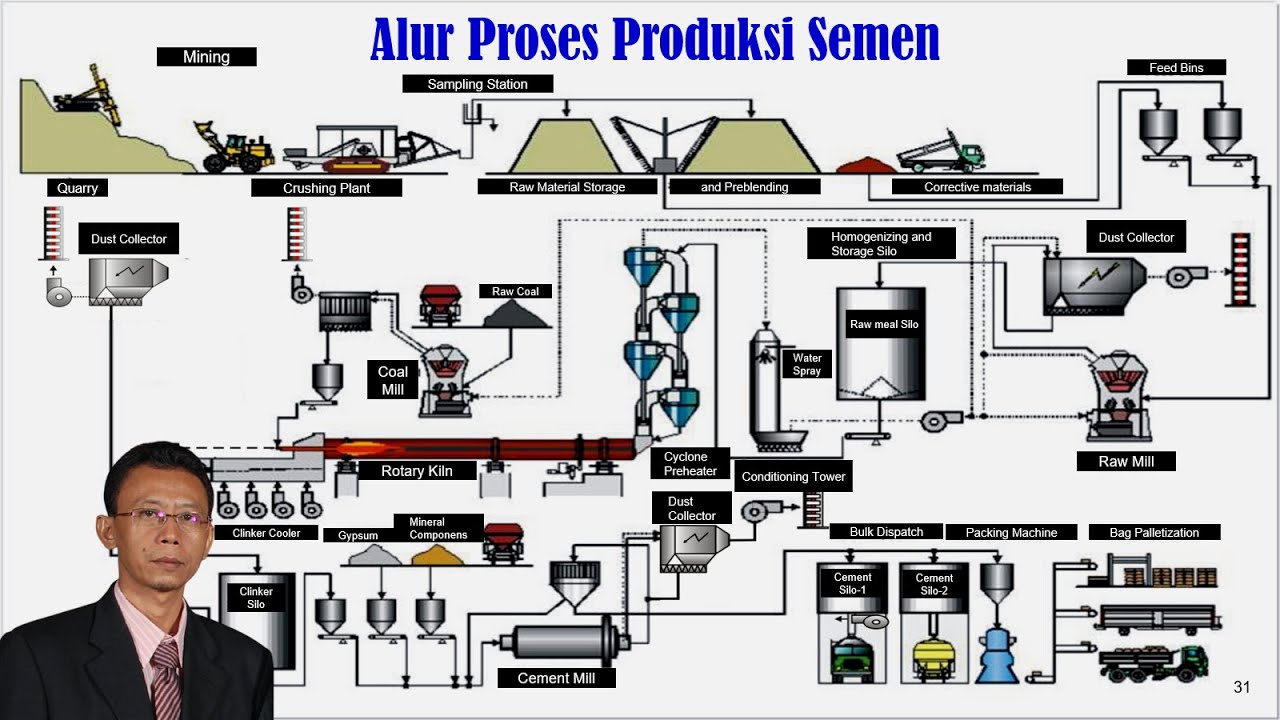

Alur Proses Produksi Semen (Tahapan Proses Produksi Semen)_Indonesia

Conheça o processo de fabricação de roupas

PKWU X | PERHITUNGAN BIAYA PRODUKSI PRODUK KERAJINAN

5.0 / 5 (0 votes)