How T-Shirts Are Made In America | From The Ground Up

Summary

TLDRThis video takes viewers behind the scenes of Bella Canvas’ sustainable and ethical manufacturing process. From the cotton fields to the final product, it showcases the use of advanced automation in fabric cutting, the skilled labor involved in sewing, and the company’s commitment to eco-friendly practices. Emphasizing fair labor standards and consumer responsibility, the video highlights how businesses like Bella Canvas are setting new standards for the fashion industry. The call to action encourages viewers to make informed choices and support brands that align with their values, shaping a positive future for the industry.

Takeaways

- 😀 The fashion industry starts with simple products like t-shirts, crew necks, and hoodies, which are often mass-manufactured in large facilities.

- 😀 Consumers have the power to impact the world by supporting businesses that prioritize ethical practices and sustainability.

- 😀 Cotton, the most popular fabric globally, undergoes a lengthy process that starts in the fields, with it being picked, processed, spun, and woven into fabric before it’s dyed and used in clothing.

- 😀 Bella Canvas, a leading apparel company in the U.S., uses innovative techniques and state-of-the-art machinery to produce quality clothing in large quantities.

- 😀 The cutting process of fabrics is highly automated, with robotic machines cutting precise panels based on digital patterns, ensuring consistency and quality.

- 😀 Automation in the fabric cutting and bundling processes helps streamline mass production while maintaining high standards of precision and efficiency.

- 😀 Bella Canvas ensures that every factory in its supply chain is certified for labor law compliance, with ongoing efforts to achieve full certification by the Fair Labor Association.

- 😀 The company emphasizes 'USA Strong' by employing thousands of workers in the U.S. while also sourcing production from Central America to maintain high standards of manufacturing.

- 😀 Workers in the sewing facilities are highly skilled, with many having decades of experience, which contributes to the craftsmanship and quality of each garment.

- 😀 Bella Canvas focuses on transparency in their production processes, ensuring that their customers know the real people behind the creation of their garments.

- 😀 The company’s commitment to quality control ensures that each product, after being sewn, undergoes checks before being shipped out, reflecting the human touch in mass production.

Q & A

What is the main focus of the video script?

-The main focus of the video script is to provide an in-depth look at the process of fabric manufacturing, from cotton cultivation to the final product, and to highlight the importance of ethical and sustainable production practices in the fashion industry.

How is cotton processed before it becomes fabric?

-Cotton is harvested, cleaned to remove impurities, and then spun into fibers. The fibers are then combed and ring spun to create a softer feel, before being woven into a raw fabric that is strong enough for clothing.

What happens after fabric is dyed in the production process?

-Once the fabric is dyed, it is transported to large cutting tables, where it is stacked in multiple layers and cut into specific designs using automated cutting machines. The cut pieces are then sent to sewing facilities for assembly.

What is the role of the robotic cutting machines in the manufacturing process?

-The robotic cutting machines are programmed to follow digital patterns, cutting the fabric precisely according to the designer’s specifications. These machines also vacuum the fabric to keep it flat, ensuring consistency in the cuts.

How does Bella Canvas ensure high-quality production in their factories?

-Bella Canvas invests in advanced automation, skilled labor, and thorough logistics to ensure consistent and high-quality production. Their facilities in Los Angeles feature cutting-edge equipment and a dedicated team of workers who are trained to maintain quality control throughout the process.

How does automation impact the sewing and fabric handling process?

-Automation, such as laser-guided systems for fabric transport and robotic cutting machines, helps streamline the process, ensuring accuracy and efficiency. However, skilled workers are still required for tasks such as sewing, where expertise is needed for proper assembly.

What is the purpose of the laser-guided system in the fabric bundling process?

-The laser-guided system helps move and organize the fabric efficiently. It activates when the fabric crosses a path, ensuring that fabric pieces are properly aligned and transported for the next stage of production.

What certification does Bella Canvas ensure their supply chain meets?

-Bella Canvas ensures that every factory in their supply chain is 100% certified by the American Apparel and Footwear Association (AAFA) for compliance with labor laws. They are also working towards Fair Labor Association (FLA) certification for their entire supply chain.

How does Bella Canvas manage to create a product that meets mass-market needs?

-Bella Canvas designs their products with a wide range of body types in mind. They use a base size for fittings, starting with a medium men’s size and testing designs across multiple sizes to ensure a good fit for various body shapes and sizes.

What is the 'USA strong' initiative mentioned in the video?

-The 'USA strong' initiative refers to Bella Canvas' commitment to employing thousands of workers in the United States for aspects of their production, while also sourcing materials from global locations. This initiative promotes American labor while still maintaining global operations.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

GREBEG PABRIK POLYGON! (LAGI) | English Subtitle

How MotorCycles Are REALLY Made

Kepoin Pabrik Makanan Kalengan - PART 3 | SI UNYIL KOMPILASI

What's the purpose of having so many roadside trees in Singapore? | Tell Me More

How Mirrors are Made | History of Mirrors from 8,000 BC to Modern Day

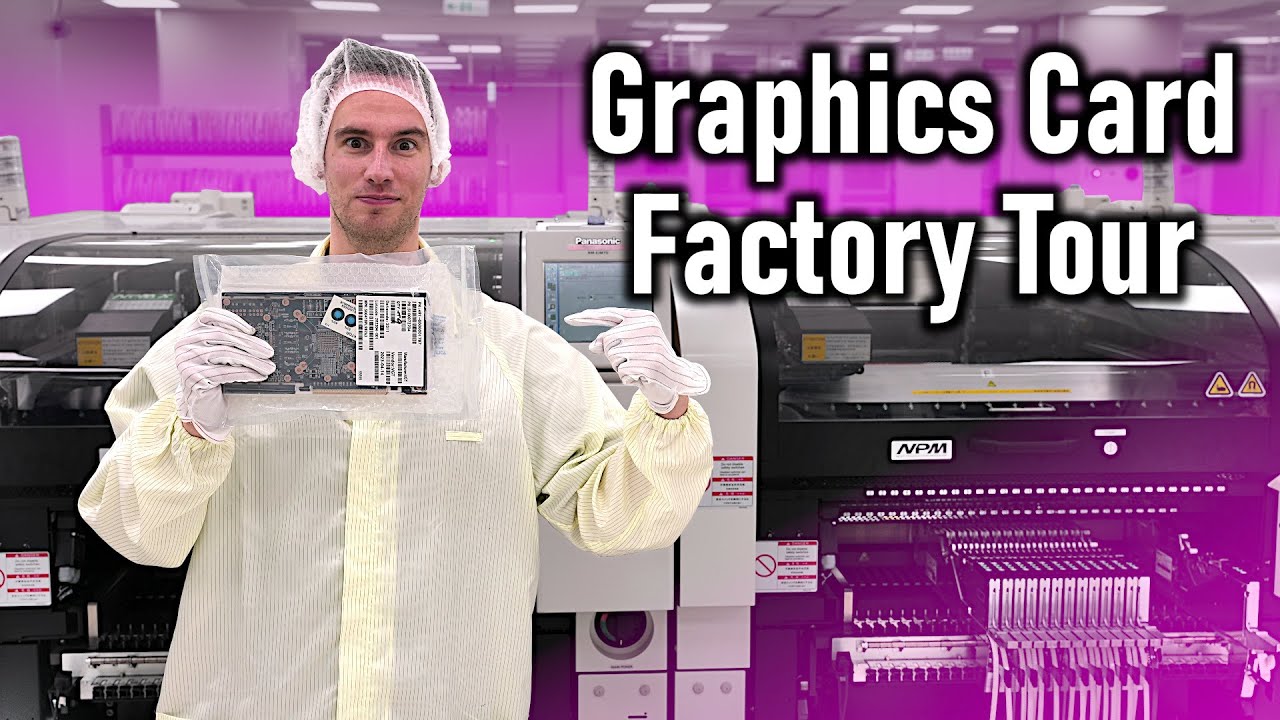

How Graphics Cards are made - Insane PowerColor Factory Tour

5.0 / 5 (0 votes)