What are the Differences between DCS and SCADA?

Summary

TLDRThis video script from RealPars offers a comparative analysis between SCADA and DCS systems, highlighting their similarities and differences. It explains that while both systems are used for plant supervision and control, they differ in their Human Machine Interface (HMI) integration, with DCS having a more integrated approach, eliminating the need for additional software. The script also touches on the programming aspects, noting that DCS systems facilitate faster integration with predefined functions, but SCADA systems may offer faster processing times. It concludes by emphasizing that the choice between SCADA and DCS depends on specific project requirements, such as communication architecture openness, time sensitivity, and safety concerns.

Takeaways

- 🤖 Both SCADA and DCS are systems used for supervision and control of plants, with similar roles in automation.

- 🖥️ SCADA systems present data to operators for decision-making and control plant functions, while DCS has a similar role but is typically integrated within the system.

- 📊 HMI (Human Machine Interface) panels serve as the primary graphical interface for interaction between operators and automated processes in both SCADA and DCS systems.

- 💻 HMI panels can come from various manufacturers or be industrial computers, requiring additional software for programming, except in DCS where they're often integrated.

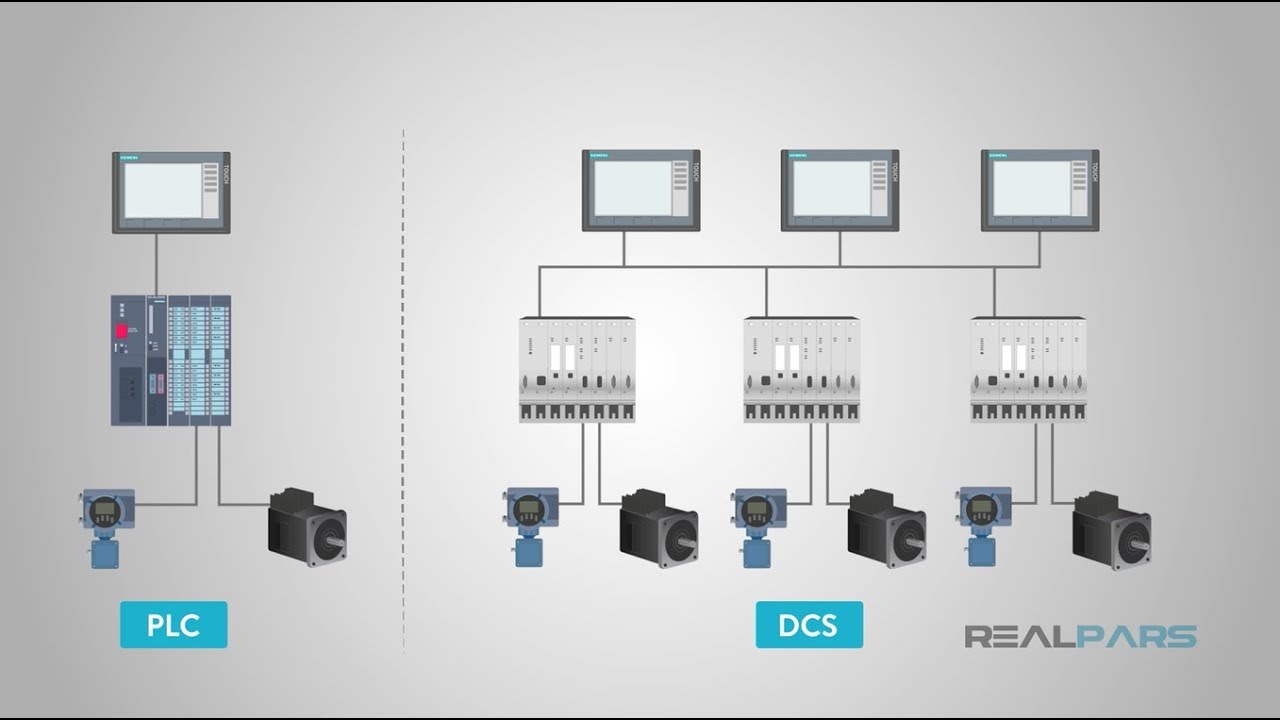

- 🔗 SCADA systems may use different manufacturers for PLCs, RTUs, and HMI, whereas DCS typically has integrated interfaces, reducing the need for extra software.

- 🛠️ Programming in SCADA involves writing code for controllers, with the possibility of reusing code through custom function blocks and Add on Instructions (AOIs).

- 🚀 DCS systems have predefined functions that facilitate faster integration, though they still require some coding.

- 🕒 Processing times in DCS can be slower compared to SCADA, which might affect time-sensitive processes.

- 🔌 Communication in SCADA systems is adaptable to changing technologies, while DCS also adapts but may have proprietary communications that are challenging.

- 🛡️ For safety-critical applications, DCS is traditionally preferred, but modern SCADA systems with safety processors are also viable options.

- 📈 In the current market, the choice between SCADA and DCS depends on specific needs such as processing speed, communication architecture, and safety requirements.

Q & A

What are the main components of a SCADA system?

-A SCADA system consists of both software and hardware components that enable supervision and control of plants, both locally and remotely.

How is a DCS similar to a SCADA system?

-A DCS, like a SCADA system, is a collection of components used for supervising and controlling plant operations, with the goal of automating processes.

What is the primary function of an HMI panel in plant automation?

-Human Machine Interface (HMI) panels serve as the primary graphical interface between plant processors and the operators, allowing interaction and control of processes.

Can HMI panels be procured from different manufacturers?

-Yes, HMI panels can be procured from various manufacturers such as Siemens, Allen Bradley, GE, Schneider Electric, or independent manufacturers like Red Lion.

What additional software is typically required for programming an HMI?

-Additional software is needed to program an HMI, such as WinCC for Siemens, FactoryTalk View for Allen Bradley, Vijeo Designer or Citect for Schneider Electric, depending on the manufacturer.

What is the advantage of using the same manufacturer for both PLC and HMI?

-While it might seem advantageous to use the same manufacturer for PLC and HMI, it does not necessarily mean that the tag database of the processor will be available for use in the HMI, as some vendors require exporting, importing, or creating tags from scratch.

How do SCADA and DCS systems differ in terms of their graphical interfaces?

-SCADA systems may use HMIs or computers from different manufacturers, while DCS systems typically have integrated graphical interfaces within the DCS system, eliminating the need for additional software.

What are the 'brains' of a SCADA system?

-The 'brains' of a SCADA system include Programmable Logic Controllers (PLCs) and Remote Terminal Units (RTUs), which require programming to execute essential plant operations commands.

How have DCS systems facilitated faster integration in plant automation?

-DCS systems have many predefined functions that can be customized and deployed for various applications, which helps in faster integration by reducing the time spent on writing code for commonly used functions.

What is the impact of slower processing times in DCS systems?

-Slower processing times in DCS systems may impact time-sensitive processes, although this is not necessarily problematic as it depends on the specific requirements of the plant operations.

How do SCADA and DCS systems compare in terms of safety?

-While DCS systems have traditionally been favored for safety-critical applications due to their proprietary communications, modern SCADA systems can also be selected for safety-critical applications with the use of safety processors.

What are the key differences between SCADA and DCS systems in today's market?

-In today's market, DCS systems offer integrated operator interface software with tag databases, while SCADA systems require additional software purchases and the building or importing of tags. SCADA may have a slight advantage in time-sensitive processes due to faster processing times, and offers an open communication architecture advantage.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

What is DCS? (Distributed Control System)

How to Interpret DCS and PLC Symbols on a P&ID

DISTRIBUTE CONTROL SYSTEM (DCS) SISTEM KONTROL TERDISTRIBUSI - DALAM OTOMASI INDUSTRI

Alle Wahlprogramme aller größeren Parteien erklärt | EU-Wahl 2024

What is the Difference Between PLC and DCS?

Introduction To SCADA System

5.0 / 5 (0 votes)