Safety for the machine shop

Summary

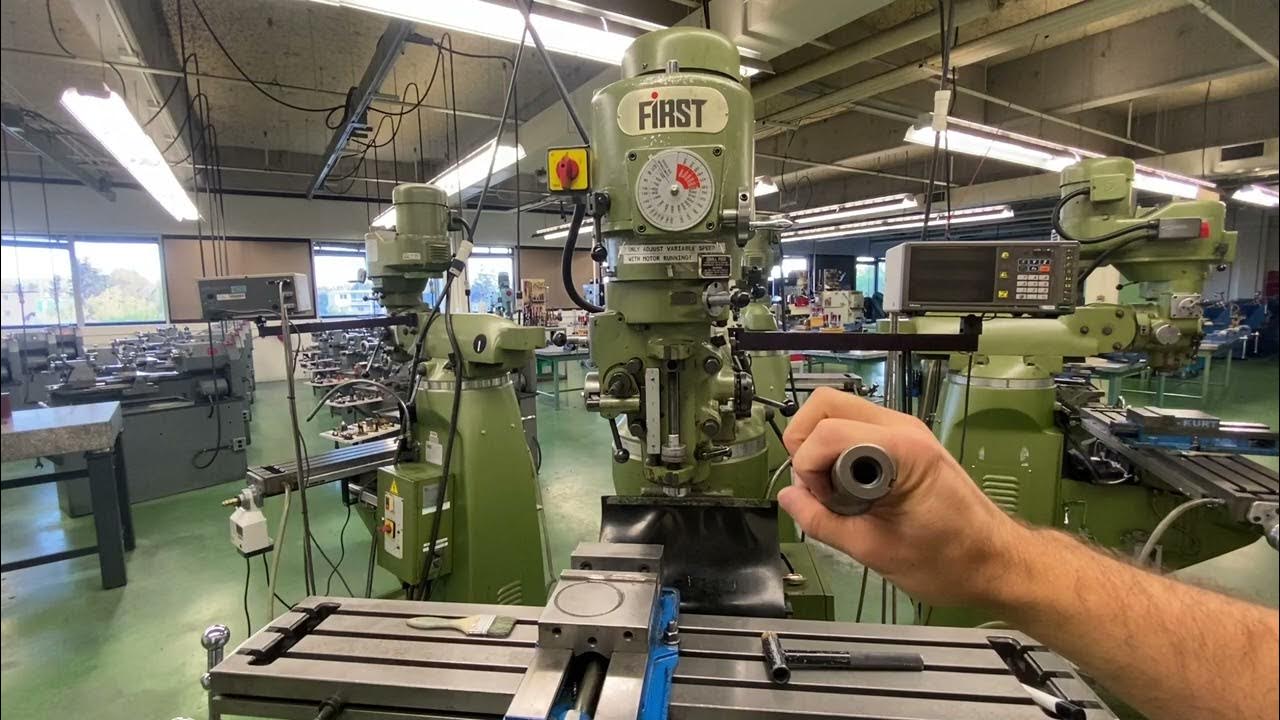

TLDRIn this video, Michael Rice emphasizes the importance of machine shop safety, focusing on mental engagement, proper PPE, and avoiding distractions. He outlines specific safety measures for lathes and mills, including securing chucks, ensuring tool and part tightness, and maintaining a clean workspace. He also addresses the dangers of using cell phones and headphones, and stresses the need for attentiveness and finesse when operating machinery to prevent accidents and ensure a safe working environment.

Takeaways

- 🧠 Stay fully engaged and maintain a clear state of mind while working in the machine shop to avoid safety hazards.

- 👀 Always wear the appropriate Personal Protective Equipment (PPE), including safety glasses, long pants, and closed-toed shoes.

- 🙅♂️ Avoid bad habits like leaving tripping hazards, using chairs in the work area, or leaving machines running unattended.

- 📵 No personal cell phone use or headphones that may distract you from being fully aware of your surroundings and the machines' operation.

- 🧹 Practice good housekeeping by putting away tools, cleaning up chips, and ensuring the work area is left in better condition than when you started.

- ⚙️ Ensure the chuck key is removed when the lathe is in operation to prevent it from flying out and causing injury.

- 🔨 Check tool and part tightness on the lathe to maintain rigidity and prevent breakage or parts flying out.

- 🔧 Use files with handles to avoid injury from accidental pushes while filing, and maintain a safe distance from rotating parts.

- 🏼 Be cautious when using sandpaper to avoid wrapping it around your fingers, which can lead to injury from the machine's rotation.

- 🔨 When working with the mill, be aware of rotational hazards from the headstock and automatic feeds, and avoid pinch points between the table and the wall.

- 🔩 Use parallels to raise workpieces above the vise jaws to prevent accidental contact with the harder steel of the vise, which can cause bit breakage.

Q & A

What is the primary focus of Michael Rice's video?

-The primary focus of Michael Rice's video is machine shop safety, covering general safety rules and specific safety guidelines for different types of machines.

Why is it crucial to be fully engaged when working in a machine shop?

-Being fully engaged is crucial in a machine shop because working around rotating equipment such as chucks and mills can be hazardous, and a lack of focus can lead to accidents or safety hazards.

What personal protective equipment (PPE) is required in the machine shop according to the video?

-The required PPE includes safety glasses, long pants, closed-toe shoes, and ensuring that long-sleeved shirts have sleeves rolled up above the elbow. Gloves should not be worn around rotating equipment.

What are some bad habits to avoid in the machine shop as mentioned in the video?

-Bad habits to avoid include creating tripping hazards with cords or parts, bringing chairs into the work area, leaving tools or equipment unattended, and leaving machines running on automatic without supervision.

Why is cell phone use restricted in the machine shop?

-Cell phone use is restricted to prevent distractions and ensure full engagement in the work being done. Personal calls should be taken away from the work area with machines turned off to ensure safety.

What are the housekeeping practices emphasized in the video?

-Housekeeping practices include putting away all tools properly, cleaning up all flat spaces to remove chips, and ensuring the work area is left in better condition than when work began.

What safety measures should be taken when using a chuck in the machine shop?

-Safety measures for using a chuck include never leaving the chuck key in the chuck when the machine is running and ensuring the guard is in place during operation.

How important is tool and part tightness when working with a lathe, and why?

-Tool and part tightness is crucial for maintaining rigidity and preventing tools from breaking or parts from flying out, which could cause injury.

What are the safety considerations when filing in the machine shop?

-Safety considerations for filing include using files with handles to avoid injury from the sharp edges, proper positioning to avoid getting too close to rotating parts, and ensuring a light grip on the file.

How should sandpaper be used safely in the machine shop?

-Sandpaper should be used with a light grip, with two fingers on each side to prevent it from wrapping around fingers and causing injury. It should not be used too close to the chuck or rotating parts.

What are the specific safety hazards associated with using a mill in the machine shop?

-Specific hazards with a mill include rotational hazards from the headstock and automatic feeds, as well as pinch points between the table and the wall during automatic feed operations.

Why are parallels important when setting up a workpiece on a mill?

-Parallels are important to raise the workpiece above the vise jaws, preventing accidental contact with the harder steel of the vise, which could cause the cutting bit to break and lead to accidents.

What is the advice given for using small drill bits in the machine shop?

-When using small drill bits, one should apply gentle pressure and avoid pushing too hard to prevent the bit from breaking, which could cause pieces to fly out or become lodged in the workpiece.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Milling Machine Basic Operation and Safety

Normas de segurança no laboratório de Química

Proper Dress and PPE / Lab Safety Video Part 1

Good Microbiological Practices and Procedures (GMPP) 1: personal protective equipment (PPE)

Operating the manual lathe(Pengoperasian mesin bubut).Tugas bahasa inggris.

PPE Training - Employee Safety on Personal Protective Equipment

5.0 / 5 (0 votes)