Concrete Clips: Mechanistic Empirical Design for Pavements

Summary

TLDRThe video script discusses pavement performance, influenced by traffic loads, climate, materials, and subgrade. It emphasizes the mechanistic-empirical (ME) design approach, using structural responses and field data to predict performance. AASHTOWare Pavement ME Design software is highlighted for its calibration tools, aiming to extend pavement life to 100 years. The Federal Highway Administration (FHWA) offers resources for ME Design, promoting advanced pavement modeling and analysis.

Takeaways

- 🛣️ Pavement performance is influenced by four main factors: traffic loads, climate conditions, materials used, and subgrade soil.

- 🔍 Proper material selection and layer thickness are crucial for achieving the desired pavement design life and performance.

- 🚀 The mechanistic-empirical (ME) design approach is the latest method used in pavement design procedures.

- 📊 Structural responses like stresses, strains, and deflections are modeled using mechanistic principles in ME design.

- 🌐 Field performance data is used to calibrate the relationship between modeled structural responses and actual pavement performance.

- 💻 Design software calculates structural responses for various traffic, climatic, and subgrade conditions to model pavement distresses and smoothness loss.

- 🛠️ AASHTOWare Pavement ME Design is a next-generation software based on mechanistic principles for pavement design.

- 🔧 Calibration-assistance tools in AASHTOWare help to eliminate bias and minimize errors in pavement performance predictions.

- 🏛️ With the right materials and construction, pavements can be designed to last decades, even up to 100 years, with accurate modeling.

- 📚 FHWA provides resources, including documents and webinars, to assist with ME Design and improve pavement structure design methods.

Q & A

What are the four factors that influence pavement performance?

-The four factors that influence pavement performance are traffic loads, climate conditions, materials used in pavement construction, and the soil or subgrade on which the pavement is built.

Why is it necessary to select appropriate materials and layer thickness for pavement design?

-Proper selection of materials and layer thickness is necessary to achieve the desired design life and performance of pavement with a high degree of confidence, given the unique combination of factors impacting pavement performance.

What is the mechanistic-empirical (ME) design approach in pavement design?

-The mechanistic-empirical (ME) design approach is based on the structural response of the pavement, such as stresses, strains, and deflections, determined using mechanistic models, and calibrated with actual field performance data.

How does the AASHTOWare Pavement ME Design software contribute to pavement design?

-AASHTOWare Pavement ME Design software calculates structural responses for various traffic, climatic, and subgrade conditions, models the progression of pavement distresses and smoothness loss over time, and provides outputs to check the adequacy of a trial design.

What is the purpose of the calibration-assistance tool in AASHTOWare Pavement ME Design?

-The calibration-assistance tool helps determine if there is any bias in predictions, establishes the cause of any bias if found, and optimizes calibration coefficients to eliminate bias and minimize the standard error of the estimate.

What is the significance of using proper materials and construction in pavement design?

-Using proper materials and construction is significant as it enables the design of pavements that can last for extended periods, such as 30, 40, 50, or even 100 years, provided there are accurate models and knowledge of the pavement's performance.

What resources does the Federal Highway Administration (FHWA) provide for ME Design?

-FHWA provides resources such as a comprehensive list of documents, pre-recorded webinars on various topics related to ME Design, and a link to the Pavement ME User Group website on their ME Design page.

How does ME Design reflect a change in the methods engineers use to design pavement structures?

-ME Design reflects a change by taking advantage of advances in material mechanics, axle-load spectra, and climate data for predicting pavement performance, marking a leap forward from previous pavement design procedures.

What is the role of mechanistic principles in the latest pavement design procedures?

-Mechanistic principles play a crucial role in the latest pavement design procedures by providing a framework for understanding how pavements respond structurally to various loads and conditions, which is essential for accurate design and performance prediction.

How does ME Design facilitate future development in pavement modeling and analysis?

-ME Design facilitates future development by incorporating empirical data with mechanistic models, allowing for more accurate and adaptable pavement design, which can evolve with new research and technological advancements.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Perencanaan perkerasan bandara

Ultimate Guide for Road Construction || Mastering in Road Construction

¿Qué es un pavimento?/Tipos de pavimentos

K5 Perkerasan Lentur Metode AASHTO 1993

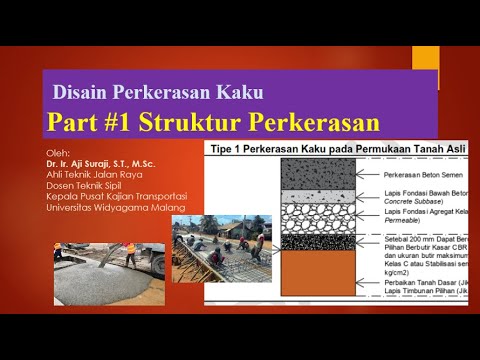

Disain Perkerasan Kaku part #1 Struktur dan Jenis Perkerasan

BAKIT SINISIRA ANG KALSADA KAHIT BAGO PA? | Civil Engineer Reacts

5.0 / 5 (0 votes)