How a Firetube Steam Boiler Works - Boiling Point

Summary

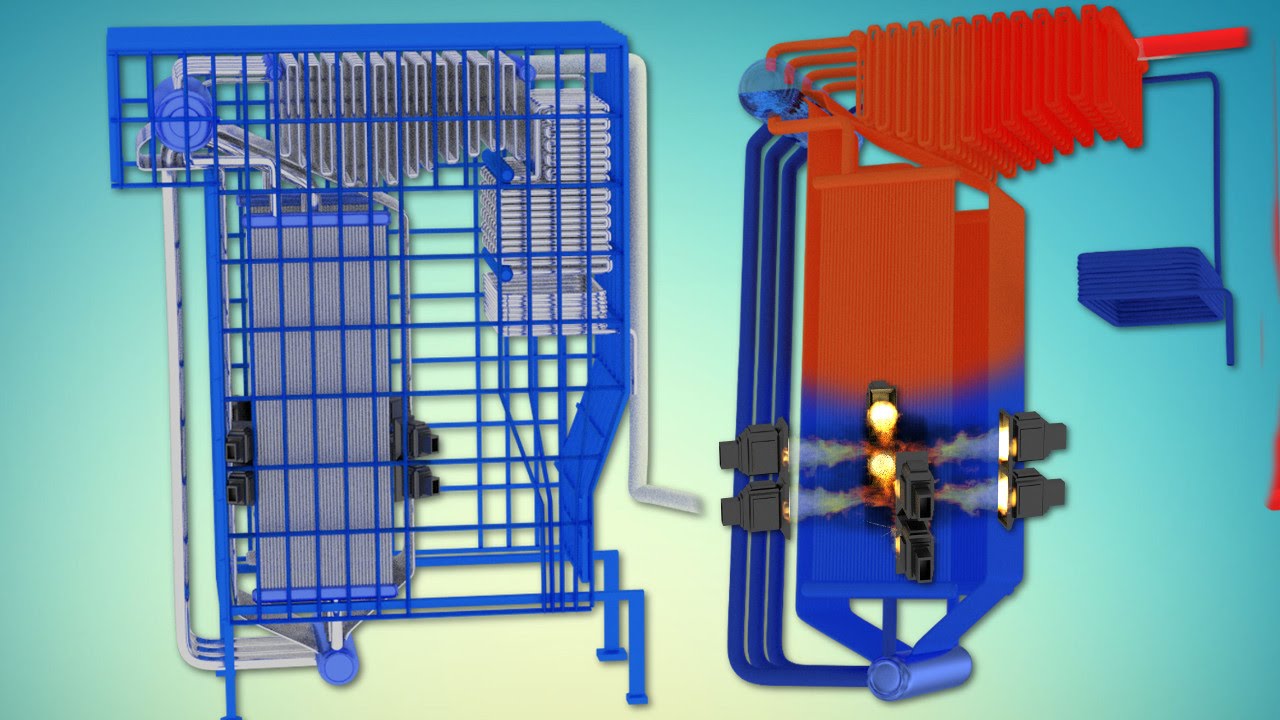

TLDRIn this episode of 'The Boiling Point,' Steven Taylor from Rental and Equipment discusses firetube boilers, focusing on their operation and efficiency. He explains how the flame and gases move within the boiler, affecting steam production. Taylor highlights the importance of tube design and pressure in determining a boiler's efficiency and capacity. The video also touches on the advantages of firetube boilers over watertube boilers, especially for smaller operations, and the significance of maintaining low total dissolved solids in water to prevent it from being sucked out with the steam.

Takeaways

- 🔥 The discussion focuses on firetube boilers, specifically their structure and function.

- 💡 Firetube boilers have a central burner that directs the flame down the Morison tube, which then transfers heat to surrounding water to produce steam.

- ⚙️ The design pressure of a firetube boiler (e.g., 150 PSI) is determined by the thickness of the steel and adherence to ASME code standards.

- 🚀 Higher pressure in a boiler results in lower efficiency because more energy is required to generate steam.

- 🔧 XID tubes are often used to improve heat transfer and efficiency in firetube boilers.

- 💨 A 150 horsepower boiler typically produces around 5,000 pounds of steam per hour.

- ☕ The steam generation process in a boiler is similar to how a tea kettle works, with steam collecting in the upper area of the boiler.

- 💧 Proper maintenance of water quality and TDS levels prevents water from being carried out with the steam.

- 💲 Firetube boilers are generally more economical than watertube boilers for smaller applications.

- 🔄 Firetube boilers are better suited for batch processes due to their larger steam holding area, providing more steam availability when needed.

Q & A

What is the main topic of discussion in the 'Boiling Point' episode?

-The main topic of discussion in the 'Boiling Point' episode is the firetube boiler, specifically how it works and its various aspects such as design, efficiency, and steam production.

What is a firetube boiler and how does the flame move within it?

-A firetube boiler is a type of boiler where the combustion gases pass through a series of tubes, and the water surrounds these tubes. The flame enters through the center, known as the Morison tube, and moves through the tubes, transferring heat to the water surrounding them.

What is the significance of the Morison tube in a firetube boiler?

-The Morison tube is the central part of the firetube boiler where the flame enters and travels down. It is crucial for the heat transfer process as the hot gases pass through it, transferring heat to the water surrounding the tubes.

How does the pressure of a firetube boiler affect its efficiency?

-Higher pressure in a firetube boiler results in lower efficiency because more energy is required to heat the water to create higher pressure steam.

What is the role of tubes in enhancing the efficiency of a firetube boiler?

-The efficiency of a firetube boiler is enhanced by using extended surface tubes, which increase the surface area for heat transfer, allowing for more efficient steam production.

What is the typical steam production rate for a 150 horsepower firetube boiler?

-A 150 horsepower firetube boiler typically produces between 50 to 100 pounds of steam per hour.

Where does the steam disengage from the water in a firetube boiler?

-In a firetube boiler, the steam disengages from the water in the upper part of the boiler where there is no water, only steam and gases.

Why does the water not get sucked out with the steam in a firetube boiler?

-The water does not get sucked out with the steam as long as the water is pure and the total dissolved solids (TDS) are within limits. The pressure in the boiler holds the water in place, allowing only the steam to escape.

What is the advantage of using a firetube boiler over a watertube boiler in smaller applications?

-A firetube boiler is more economical for smaller applications as it is less expensive to manufacture and operate compared to a watertube boiler.

How does the steam holding capacity of a firetube boiler benefit batch processes?

-The firetube boiler has a larger steam disengaging area, which allows it to hold more steam. This is beneficial for batch processes that require a large amount of steam in a short period, as the firetube boiler can provide it quickly.

What is the purpose of the refractory material used in the firetube boiler?

-The refractory material in the firetube boiler is used to withstand high temperatures and to ensure that the gases turn and move through the tubes efficiently. It is designed to have minimal shrinkage to prevent cracks and other issues.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)