Motor Basics

Summary

TLDRThis training program by Yaskawa America introduces the fundamentals of three-phase induction motors, exploring their components, electromagnetic induction, and operational principles. It covers key concepts such as synchronous and rated speeds, slip, speed-torque curves, and NEMA motor designs. Participants learn about the significance of motor nameplates and different enclosure types. The program aims to provide a solid understanding of induction motors, preparing viewers for further learning on variable frequency drives, and emphasizes Yaskawa's commitment to quality and customer satisfaction.

Takeaways

- 😀 Three-phase induction motors are the most widely used AC motors, found in thousands of applications due to their torque production, low cost, and maintenance.

- 😀 The key components of a three-phase induction motor are the stator and rotor, which work together to convert electrical energy into mechanical energy.

- 😀 Electromagnetic induction occurs when a magnetic field induces current in a conductor, crucial for the operation of induction motors.

- 😀 Synchronous speed is the speed of the rotating magnetic field in the stator, while rated speed is the mechanical speed of the rotor at rated load.

- 😀 The difference between synchronous speed and rotor speed is known as 'slip,' which varies with the load on the motor.

- 😀 The NEMA design classifications (A, B, C, D) dictate the torque and slip characteristics of induction motors for different applications.

- 😀 A Speed Torque Curve illustrates how motor torque changes as the motor approaches its rated speed and how it behaves under varying loads.

- 😀 Motor nameplates provide critical specifications, including horsepower, rated voltage, current, frequency, and speed, essential for proper motor selection and application.

- 😀 Different types of motor enclosures (e.g., ODP, TENV, TEFC) protect the motor components based on the application environment.

- 😀 Understanding the construction and operation of induction motors is foundational for utilizing variable frequency drives and optimizing motor performance.

Q & A

What are the two major components of a three-phase induction motor?

-The two major components are the stator and the rotor, which work together to convert electrical energy into mechanical energy.

How does electromagnetic induction occur in an induction motor?

-Electromagnetic induction occurs when the stator produces a rotating magnetic field, which induces voltage in the rotor bars, creating an opposing magnetic field.

What is synchronous speed, and how is it calculated?

-Synchronous speed is the speed of the rotating magnetic field in the stator, calculated using the formula 120 times the frequency (f) divided by the number of poles (p).

What is 'slip' in the context of induction motors?

-Slip is the difference between the synchronous speed of the stator's magnetic field and the actual mechanical speed of the rotor.

What happens to the rotor speed as the load on the motor increases?

-As the load increases, the rotor speed decreases, leading to an increase in slip and a corresponding increase in torque.

What are the four NEMA motor design types, and why are they important?

-The four NEMA design types are A, B, C, and D, each with unique torque, speed, and slip characteristics suited for different applications.

What is the significance of the motor nameplate?

-The motor nameplate provides essential information about the motor's specifications, including horsepower, rated speed, voltage, current, and design type.

What is the purpose of an overload relay in an induction motor?

-An overload relay protects the motor from damage due to overheating by interrupting the current when the motor exceeds its rated load.

What are the different types of induction motor enclosures mentioned in the transcript?

-Types of enclosures include Open Drip-Proof (ODP), Totally Enclosed Non-Ventilated (TENV), Totally Enclosed Fan-Cooled (TEFC), and Totally Enclosed Blower Cooled (TEBC), among others.

How does the number of poles in the stator affect the motor's performance?

-Increasing the number of poles in the stator reduces the synchronous speed and changes the torque characteristics of the motor, allowing for higher torque at lower speeds.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Practical Marine Electrical Knowledge: Program 4. Motors and Starters

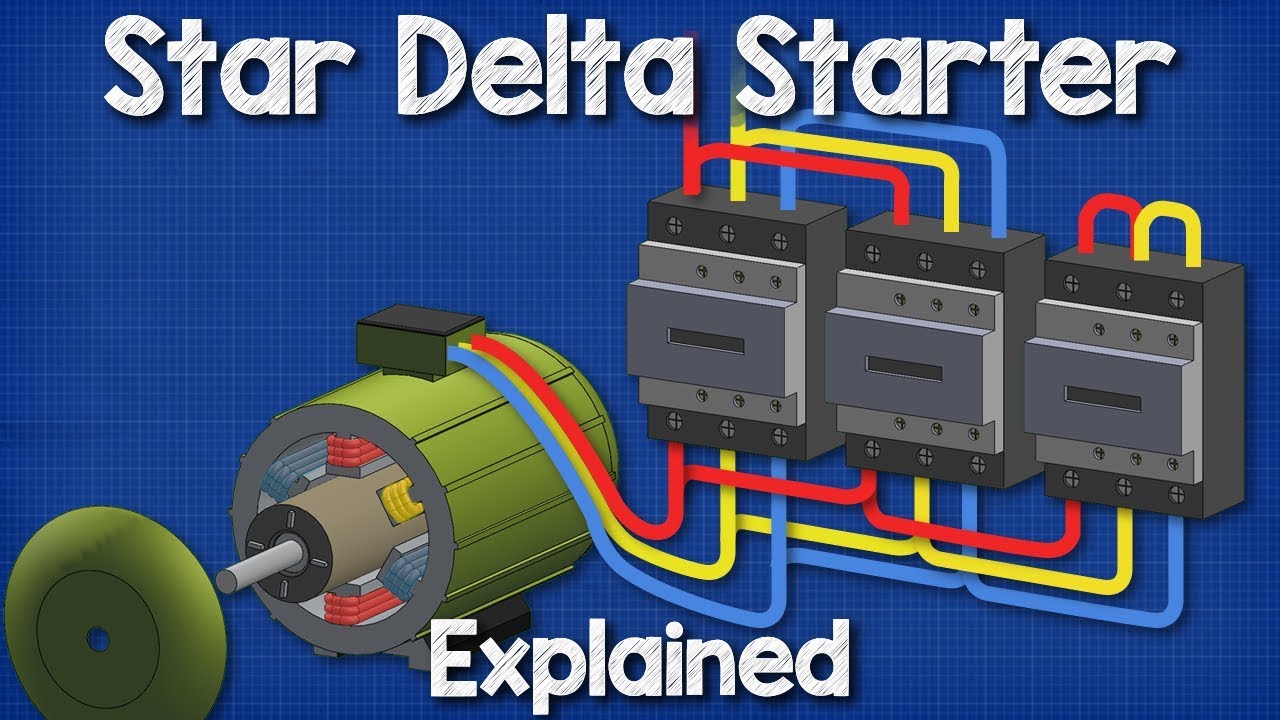

Star Delta Starter Explained - Working Principle

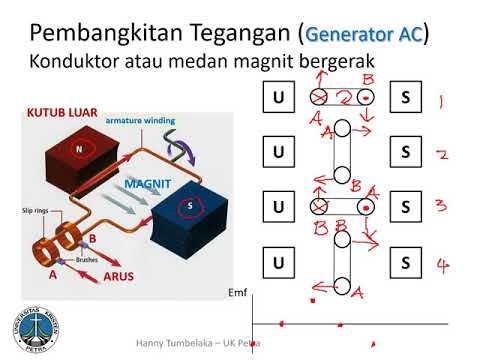

Prinsip Kerja Generator AC

FISIKA KELAS XII | INDUKSI ELEKTROMAGNETIK - Fluks Magnet, Hukum Faraday, dan Hukum Lenz

AC MOTORS AND GENERATORS

How does a fan work ? | Single phase induction motor

5.0 / 5 (0 votes)