Introduction to thermistors

Summary

TLDRThis TI Precision Labs video explores thermistors, temperature sensors known for their wide use in various industries. Thermistors, or thermal resistors, change resistance with temperature, offering a cost-effective solution with a broad selection of types, resistance values, and tolerances. The video distinguishes between NTC and PTC thermistors, focusing on NTC and linear PTC types for temperature sensing due to their reliability and consistency. It also discusses the importance of considering tolerance across the temperature range and the impact of drift and response times on thermistor performance.

Takeaways

- 🌡️ Thermistors are temperature sensors whose resistance changes with temperature, used in various applications like self-resetting fuses and heating elements.

- 📊 They are available in different types, primarily NTC (Negative Temperature Coefficient) and PTC (Positive Temperature Coefficient), with further distinctions in linear and nonlinear characteristics.

- 🔍 NTC thermistors decrease in resistance as temperature rises, while PTC thermistors increase, making them suitable for different sensing needs.

- 📉 Linear PTC thermistors, also known as solistors, offer advantages like lower drift and smaller thermal mass, contributing to reliability in applications.

- ⏱️ NTC thermistors, made from ceramic metal oxides, are known for larger tolerances and greater drift over time compared to linear PTCs.

- 📊 The tolerance percentage of thermistors is crucial, as it affects the accuracy of temperature measurements, especially as it varies across different temperatures.

- 🛠️ Thermistors are chosen for their wide range of available packages, resistance values, and tolerances, which can impact both cost and performance.

- 🔗 The total accuracy of a thermistor-based solution is influenced by the tolerance of the thermistor and other components in the signal chain.

- ⚙️ Designing with thermistors involves considering factors like drift, response time, and tolerance to optimize the temperature sensing solution.

- 🔗 For more detailed information and to explore thermistor technologies further, the video suggests visiting ti.com/thermistors.

Q & A

What is a thermistor?

-A thermistor is a thermal resistor, a simple discrete two-terminal device whose effective resistance values change with temperature.

What are the common applications of thermistors?

-Thermistors are used as self-resetting fuses, self-regulating heating elements, and temperature sensors in various markets including automotive, industrial, personal electronics, and aerospace and defense.

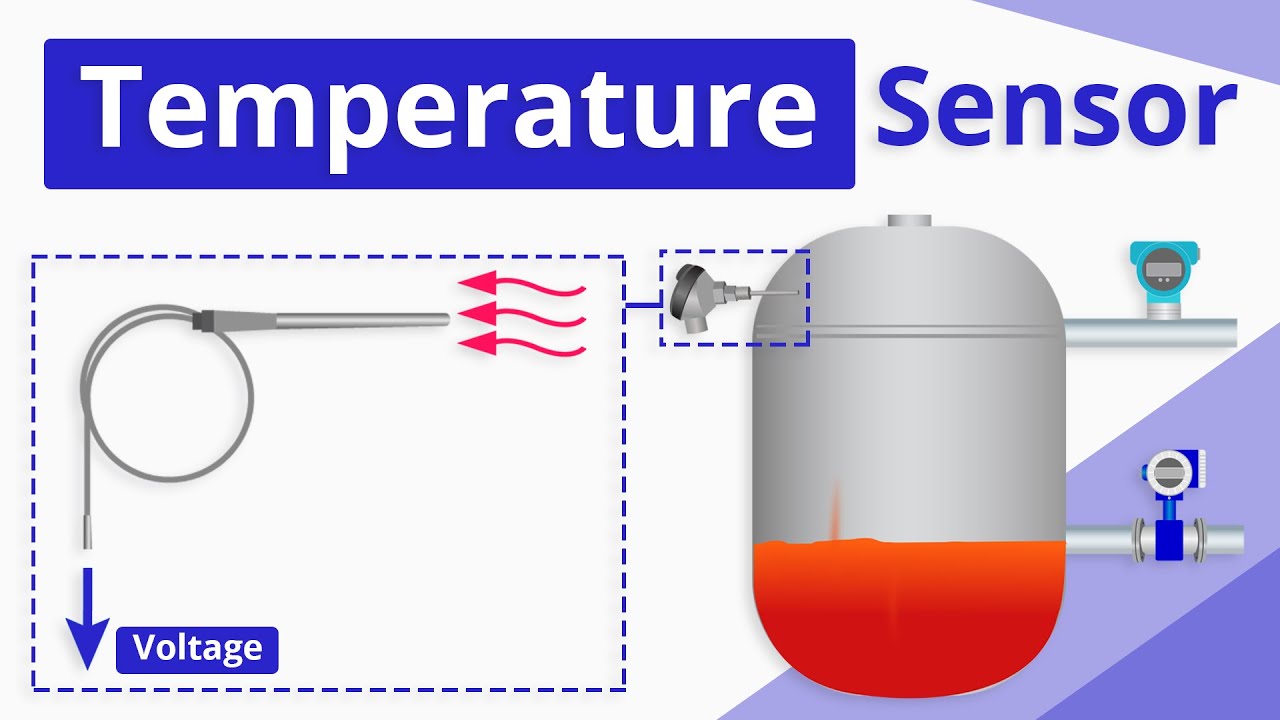

How does a thermistor work in a temperature sensing system?

-In a temperature sensing system, a thermistor's resistance changes with temperature. An ADC measures the voltage drop across the thermistor, and software calculates the corresponding temperature.

What are the two main types of thermistors used for temperature sensing?

-The two main types of thermistors used for temperature sensing are Negative Temperature Coefficient (NTC) and Linear Positive Temperature Coefficient (Linear PTC) thermistors.

What does NTC stand for and how does it behave with temperature?

-NTC stands for Negative Temperature Coefficient, meaning the thermistor's resistance decreases as the temperature rises.

How does a Linear PTC thermistor differ from an NTC thermistor?

-Linear PTC thermistors are made from silicon and have a linear change in resistance with temperature. They have lower drift, smaller thermal mass, and less variation in manufacturing process compared to NTC thermistors.

What is the significance of the tolerance percentage in thermistors?

-The tolerance percentage indicates the error between the thermistor's actual and typical effective resistance values provided by the manufacturer. It's important for understanding the accuracy of the thermistor across different temperatures.

Why might a thermistor need calibration?

-Thermistors may need calibration to account for variations in resistance across temperature, ensuring accurate temperature measurements, especially for NTCs which can vary quite a bit.

How do the response times of NTC and Linear PTC thermistors compare?

-Some Linear PTCs can respond almost three times faster to temperature changes than comparable NTCs, which may be crucial in critical situations to prevent thermal failures.

What factors should be considered when choosing a thermistor for a temperature sensing application?

-When choosing a thermistor, consider factors such as the required accuracy, tolerance across temperature, drift over time, response time, and the cost associated with the thermistor's package and resistance values.

Why are thermistors still popular despite the availability of temperature sensor ICs?

-Thermistors remain popular due to their large selection, availability in various packages, resistance values, and tolerances, providing both high and low-cost options, and their long history of reliable use in many industries.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)