Flatten a Board with a Hand Plane | Build a Cutting Board with Hand Tools | Hand Plane Foundations

Summary

TLDRThis woodworking tutorial outlines the process of transforming a rough board into a piece ready for joinery. It emphasizes the importance of using a saw to reduce warps like cup, bow, and twist before planing. The video demonstrates how strategic sawing can minimize planing and preserve board thickness. It also covers the use of winding sticks to check for warps and the progression from using a jack plane to a smoothing plane for achieving a flat, square surface ready for joinery.

Takeaways

- ✂️ The initial step in preparing a board for joinery is to cut it into smaller, oversized pieces to reduce warping.

- 🪓 Using a saw to make strategic cuts is more efficient for dealing with warp than using a plane.

- 📏 Cross-cutting a board can reduce bow, while ripping can reduce crook, but cross-cutting tends to preserve more thickness.

- 🌀 To minimize twist, cross-cutting is recommended as it preserves more of the board's thickness compared to ripping.

- 🔍 Winding sticks are used to check for bow, cup, and twist, providing a visual and physical assessment of the board's straightness.

- ⚖️ When planing, start with the cup side down for stability and to ensure an even reduction of high spots.

- 🔨 Planing across the grain is easier and requires less effort, but diagonal planing can help remove cross-grain marks and flatten the board.

- 🛠️ Maintain good planing form to avoid creating stop lines or cutting edges low, which can affect the board's flatness.

- 🔄 Regularly check the board's flatness and wind with straight edges and winding sticks to ensure consistent progress.

- 🔄 Switch to a smoothing plane with a flatter camber towards the end to achieve a finer, more even surface for joinery.

Q & A

What is the first step in preparing a board for joinery according to the script?

-The first step is to take a full-length board and cut it into smaller, but still oversized, pieces.

Why is using a saw preferred over a plane for initially reducing warp in a board?

-Using a saw is a much faster way to deal with warp than using a plane, as it allows for strategic cuts while still leaving the parts oversized, minimizing the impact of warp and reducing the amount of planing necessary.

How can ripping a board into narrower boards reduce the impact of cup warp?

-Ripping a board into narrower boards reduces the impact of cup warp by spreading the curvature across a smaller width, thus requiring less material to be removed to achieve flatness.

What is the effect of cross-cutting a board on bow reduction?

-Cross-cutting a board into shorter lengths can significantly reduce bow, as the curvature along the length is divided into smaller sections, lessening the overall bow in each piece.

How does cross-cutting versus ripping affect the width of a board when straightening a crook?

-Ripping can remove a crook at the expense of some board width, which may not be critical if width is not an issue. However, if the width is important, cross-cutting first requires less width removal to straighten the edge.

What is the recommended approach to reduce twist in a board?

-Cross-cutting tends to preserve the most amount of thickness when reducing twist, as twist often results from tension in the board. Ripping can release this tension, potentially causing the board to twist more.

Why is it important to check the board with winding sticks after cross-cutting?

-Checking with winding sticks after cross-cutting helps to identify any remaining bow, cup, or twist, allowing for targeted planing to achieve a flat and straight board.

What is the benefit of using a longer plane when planing a board?

-A longer plane, like a jack plane, helps to bridge the outer edges of the board more effectively, making it easier to achieve a flat surface, especially when dealing with larger or more warped boards.

How does planing diagonally help in flattening a board?

-Planing diagonally helps to remove cross-grain planing marks and can bring high areas in the center of the board closer to being level with the edges, reducing bow and improving flatness.

Why is it recommended to plane along the grain towards the end of the flattening process?

-Planing along the grain helps to remove any cross-grain ridges and ensures a smooth, even surface. It also allows for a more precise check of the board's flatness and helps to avoid over-planing.

What is the significance of checking for twist in multiple spots on the board?

-Checking for twist in multiple spots ensures that the entire board is flat and true, not just in certain areas. This is crucial for joinery, where the board must be uniformly flat to ensure a tight fit.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

How to Use a Chisel, Tips and Tricks for the Beginner to Intermediate Woodworker

Land Development 101 - Introduction Video #1 (Land Development)

Woodworking Masterclass S01 E01

Beginner Hand Tool Woodworking Project. Spalted Beech Pencil Case.

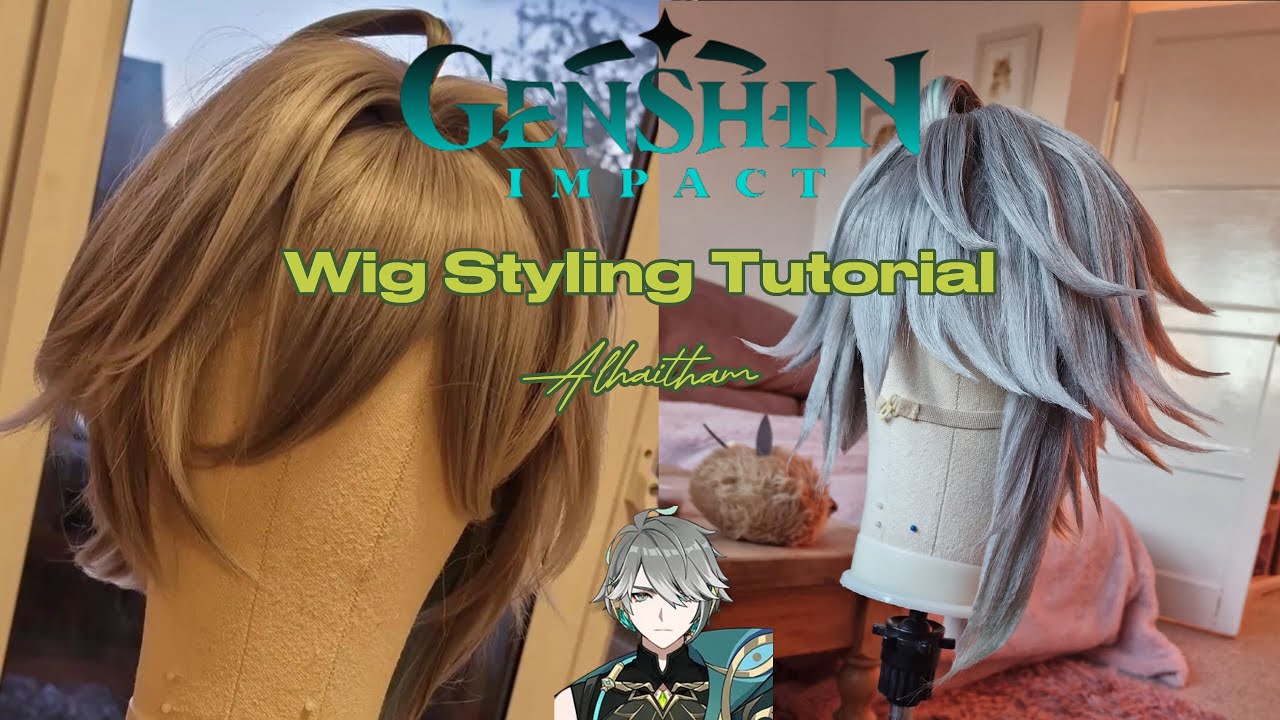

Cosplay Wig Styling Tutorial - Alhaitham

Creating PLANS IN LAYOUT from a SketchUp Model - COMPLETE PROCESS!

5.0 / 5 (0 votes)