5 Consigli per smaltare correttamente la ceramica

Summary

TLDRIn this insightful video, the instructor shares five invaluable tips for achieving successful glaze application in ceramics. They emphasize the importance of correctly measuring glaze density, thoroughly mixing the glaze, meticulously cleaning the pieces, previewing the immersion process, and using wax resist on the feet or base. The instructor acknowledges the common struggles faced by students during this crucial stage and aims to provide practical guidance. With a compassionate tone, they reassure viewers that mistakes are normal and offer advice on rectifying glaze mishaps through additional practice. Overall, this concise yet comprehensive video promises to demystify the daunting task of glaze application.

Takeaways

- 👍 Measure the glaze density correctly by doing a test dip before glazing the final piece.

- 🥄 Mix the glaze thoroughly, using a utensil to incorporate any settled material at the bottom.

- ⚖️ Always sieve the glaze after mixing to remove any lumps.

- 🧽 Clean the piece thoroughly of any dust before glazing to avoid defects like pinholes.

- 🧪 Test the fit of the piece in the glazing container before dipping to ensure it can be submerged and turned easily.

- 🪣 Apply a resist wax to the feet or base of the piece for a professional, clean finish.

- 🔄 If the first glaze attempt fails, clean off the glaze, let the piece dry for 24 hours, and try again.

- 🏋️♀️ Glazing takes practice, so don't be discouraged by initial failures.

- ❓ The glazing process is often the most dramatic and challenging part for ceramics students.

- 📝 The video provides five key tips for successful glazing.

Q & A

What are the five main tips provided in the video for successful glaze application?

-The five main tips are: 1) Measure the correct density, 2) Mix the glaze thoroughly, 3) Clean the pieces properly before glazing, 4) Test the fit of the piece in the container before dipping, and 5) Apply wax resist on the feet or base.

How can you check if the glaze density is correct?

-You can check if the glaze density is correct by dipping a test piece with similar thickness and material as the actual piece you want to glaze. If the test piece dries immediately after removing it from the glaze, the density is correct.

Why is it important to sieve the glaze after mixing it?

-It is important to sieve the glaze after mixing it to remove any lumps or clumps that may have formed, as these can create defects in the final glaze.

What is the purpose of cleaning the piece thoroughly before glazing?

-Cleaning the piece thoroughly before glazing helps remove any dust or debris that could cause defects in the final glaze, such as small pinholes or blemishes.

Why is it recommended to test the fit of the piece in the glazing container before dipping?

-Testing the fit of the piece in the glazing container before dipping helps ensure that the piece can be properly rotated and immersed in the glaze without any issues, which can lead to glazing failures.

What is the purpose of applying wax resist on the feet or base of the piece?

-Applying wax resist on the feet or base of the piece helps achieve a professional and clean finish, preventing glaze from adhering to those areas during the glazing process.

What should you do if the glaze application is unsuccessful on the first try?

-If the glaze application is unsuccessful on the first try, you should not discard the piece. Instead, you should clean off the glaze, allow the piece to dry completely for at least 24 hours, and then try glazing it again.

How can you ensure a smooth and even application of the wax resist?

-To ensure a smooth and even application of the wax resist, you should use a dedicated brush that is only used for applying the wax resist, and apply it thoroughly to the feet or base of the piece.

Why is glazing often considered one of the most dramatic and challenging steps in ceramics?

-Glazing is often considered one of the most dramatic and challenging steps in ceramics because it is a crucial step that can make or break the final appearance and quality of the piece, and it requires a lot of practice and attention to detail to get right.

What is the recommended approach if you notice lumps or clumps in the glaze after mixing?

-If you notice lumps or clumps in the glaze after mixing, you should sieve the glaze to remove them before proceeding with the glazing process.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Rifinitura a Secco - Scuola Ceramica Online

Smaltatura ceramica ad immersione, come smaltare la terracotta e la ceramica

Glazing Possibilities- 28 Different Approaches to Glazing Pottery!

Иван Безбородов рассказывает и показывает.

Cracking the Kiln | Matte vs. Crystalline Glazes | Ceramic Materials Workshop

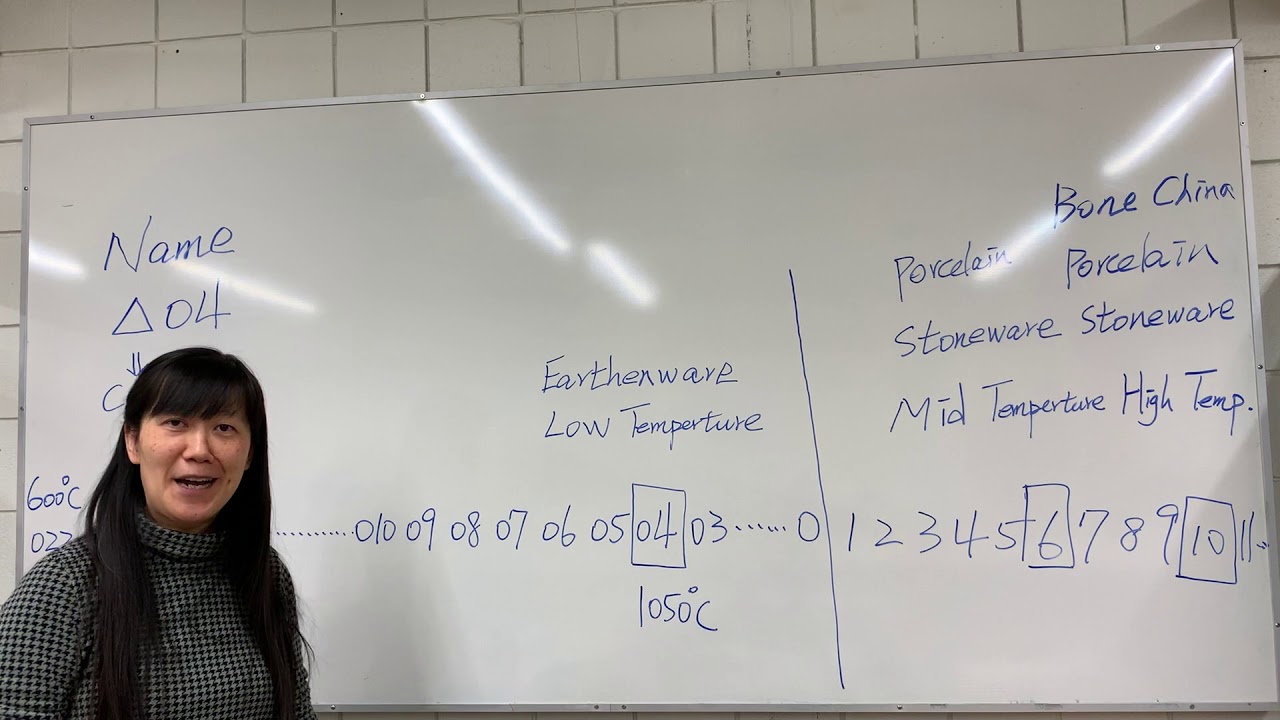

23.13 Name clay and tools, and Information for clay types and temperatures

5.0 / 5 (0 votes)