VIDEO 1 Dasar Pengelasan Las Listrik (SMAW)-Bagian Mesin Las, Kode Elektroda, Polaritas, Kekuatan.

Summary

TLDRThis educational video script introduces various components of a welding machine, focusing on electrode holders and settings. It explains the factors influencing amperage selection, such as electrode diameter, welding position, and material thickness. The script also discusses different electrode types, their pulling strength, and applications, providing a foundation for beginners in welding to understand machine parts, electrode usage, and the importance of polarity in DC welding machines.

Takeaways

- 😀 The video script is an introduction to the parts of a welding machine, aimed at those who are learning about welding for the first time.

- 🔧 The main parts of the welding machine discussed include the holder, which is used to hold the electrode, and the radiant, which is a clamping part.

- 🔌 The script explains the process of setting up the machine, including how to adjust the amperage based on various factors such as electrode diameter and welding position.

- 📏 Amperage settings are influenced by the electrode diameter, with a 3.2 mm electrode having a recommended range of 60-100 amps for flat positions and 60-100 amps for vertical and overhead positions.

- 🔨 The choice of amperage also depends on the thickness of the material being welded, with thinner materials requiring lower amperage and thicker materials requiring higher amperage.

- 🔩 The script mentions different types of electrodes, such as E6013, E7018, and E6010, each with specific characteristics and recommended applications.

- 👷♂️ E6013 electrodes have a pulling force of 60,000 pounds per square inch and are suitable for all welding positions, while E7018 electrodes are used for fillet welding and have a higher pulling force.

- 🛠 The script also discusses the importance of electrode polarity in DC welding machines, with the electrode being the anode (positive) and the workpiece being the cathode (negative).

- 🔥 The heat distribution in welding is crucial, with 70% of the heat generated in the electrode and 30% in the workpiece, affecting the welding process and the choice of electrode for different applications.

- 💡 The video script concludes with a teaser for the next video, which will cover the ignition of the electrode and the techniques involved, especially for beginners in welding.

Q & A

What is the main topic of the video script?

-The main topic of the video script is an explanation of the parts of a welding machine, specifically for those who are learning about welding for the first time.

What are the main components of a welding machine mentioned in the script?

-The main components mentioned are the holder or electrode holder, the radiant or clamping mass part, and the electrode itself.

What is the purpose of the 'slime base' in the welding process?

-The 'slime base' is used to clamp the object that needs to be welded.

What factors influence the choice of amperage in welding?

-The factors influencing the choice of amperage include the diameter of the electrode being used, the welding position (flat, horizontal, vertical, or overhead), and the thickness of the material being welded.

What is the meaning of the term 'electrode' in the context of this script?

-In this context, 'electrode' refers to the consumable part of the welding machine that conducts electricity to the workpiece.

What does the term '60 13' represent in the script?

-'60 13' represents the specification of an electrode, indicating a diameter of 3.2 millimeters and a pulling force of 60,000 pounds per square inch.

What is the significance of the numbers '70 16' and '70 18' in the script?

-The numbers '70 16' and '70 18' represent different types of electrodes with varying pulling forces and compositions, suitable for different welding positions and applications.

Why is the electrode with the marking '70 18' said to be faster for filling?

-The electrode '70 18' is faster for filling because it contains iron powder, which allows for a quicker filling of the welding material.

What is the difference between DC and DCR in terms of heat distribution in welding?

-In DC, 70% of the heat is generated at the electrode, causing it to wear out quickly and is suitable for filler or cover positions. In DCR, 70% of the heat is generated at the workpiece, resulting in deeper penetration and is suitable for hot pass or penetration welding.

What is the recommended use for thin materials in welding according to the script?

-For thin materials, it is recommended to use electrodes with lower heat generation at the workpiece to prevent burning or creating holes in the material.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Stick Welding Basics: Full Tutorial

Step by Step: How to Setup a Stick Welder

Telecurso 2000 Processos de Fabricação 14 O arco elétrico entra em ação

Mengelas Pelat Posisi di Bawah Tangan(1F, 1G) dengan Proses Las GMAW - Teknik Pengelasan

STICK WELDING 101: Getting Started With SMAW

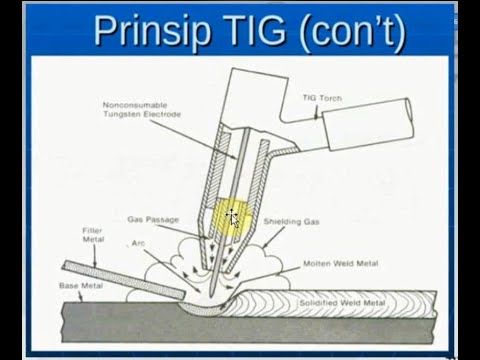

Prinsip Kerja dan Komponen Las TIG (Tungsten Inert Gas)

5.0 / 5 (0 votes)