Animasi Metode Pelaksanaan Jembatan Beton dan Rangka Baja

Summary

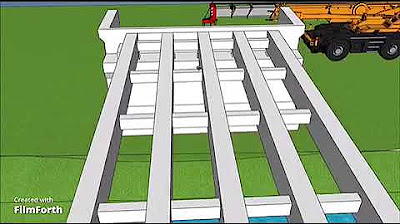

TLDRThis video provides a detailed overview of the bridge construction process, highlighting key stages such as pile driving, pillar and bridge member installation, concrete casting, and girder assembly. It also covers the steel frame bridge construction, including the installation of longitudinal beams and wind ties, followed by asphalting work on both steel and concrete bridges. The video concludes by showcasing the completed bridge, ready for vehicle passage, emphasizing the collaboration and use of heavy machinery throughout the process.

Takeaways

- 😀 Pile driving is the first step in the bridge implementation process, using hydraulic Mr files to drive piles to a predetermined depth.

- 😀 The second task involves constructing the bridge's pillars and members, starting with the installation of formwork and casting using ready-mix concrete.

- 😀 The next phase includes work in the non-girder area and the use of RCN (reinforced concrete), which is placed in the pillar support area and on the bridge after the girder installation.

- 😀 After the girder installation is complete, a diaphragm is created by casting to further support the structure.

- 😀 Once the concrete bridge floor plate has dried, the girder and the concrete bridge floor will function in a monohybrid manner.

- 😀 The steel frame is erected next, assisted by scaffolding, with heavy equipment (cranes) used to transport and install the steel frame elements.

- 😀 Steel frame elements include longitudinal beams and lower wind ties, followed by the installation of the main steel frame consisting of vertical, diagonal, and horizontal components.

- 😀 The installation of the steel frame bridge continues with the use of jufeng, a tool that helps complete the bridge on one side before connecting both sides.

- 😀 The steel frame bridge is an open steel frame bridge, 40 meters long, with individual steel frame elements measuring 5 meters each. The concrete bridge has a length of 15 meters and a width of 6.7 meters.

- 😀 Final bridge work includes adding supports on the steel and concrete bridges. The concrete bridge supports are connected to concrete structures, while the steel bridge supports are directly linked to the main steel frame.

- 😀 The last phase of the bridge implementation is asphalting, which is carried out on both steel and concrete bridges, after which the bridge is ready for vehicle passage.

Q & A

What is the first step in the bridge construction process?

-The first step in the bridge construction process is pile driving, which involves using heavy hydraulic equipment to drive piles to a predetermined depth. These piles are used as the foundation for the bridge.

What equipment is used for pile driving in the project?

-The equipment used for pile driving is a hydraulic pile driver, which is designed to ensure the piles reach the necessary depth for structural stability.

What is the purpose of the formwork in bridge construction?

-Formwork is used to shape and support the concrete during the casting process, ensuring that the concrete pillars and members of the bridge are formed correctly.

What material is used for casting the pillars in the bridge project?

-The pillars of the bridge are cast using ready-mix concrete, which is prepared off-site and then transported and poured at the construction site.

What happens after the girder installation in the bridge construction process?

-After the girder installation is completed, the diaphragm is created by casting concrete, which helps stabilize and connect the girder and the bridge structure.

How does the concrete floor plate affect the bridge's functionality?

-Once the concrete bridge floor plate has dried, the bridge begins to function as a unified structure. The girder and concrete bridge plate work together in a monolithic manner, which strengthens the overall bridge.

What is the role of scaffolding in the bridge construction?

-Scaffolding is used as a support tool during the erection of the steel frame. It provides temporary stability and safety as workers install the steel components of the bridge.

What types of steel elements are used in the bridge's construction?

-The steel elements used in the bridge include longitudinal beams, lower wind ties, and a series of vertical, diagonal, and horizontal frames, all of which are connected using steel bolts according to the design specifications.

How are the steel frame elements installed on the bridge?

-The steel frame elements are installed using heavy equipment, specifically cranes, and a simple installation process is employed. One side of the bridge is constructed until both sides can be connected.

What is the size and design of the steel frame bridge?

-The steel frame bridge is 40 meters long, with a width of 6.5 meters. The steel frame elements are designed for a span of 5 meters and are made as an open steel frame structure.

What is the final step in the bridge construction process?

-The final step in the bridge construction process is asphalting, which is carried out on both the steel and concrete bridges. After the asphalting is completed, the bridge becomes ready for vehicle traffic.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

OH BEGINI!! PROSES PEMBANGUNAN GEDUNG DARI NOL

Pekerjaan Struktur Beton Bertulang // Quality Control Pekejaan Beton part1

Metode Kerja Erection Girder Jembatan Prategang (Prestressed Girder) Bendungan Temef Nindya Karya

Golden Gate Bridge | How a Wonder was Constructed?

Animasi Pembuatan Jembatan Beton Bertulang Prodi Teknik Sipil F. Teknik Um Sumbar

Complete House Construction procedure step by step| 30 steps | घर बनाने का सही तरीका |

5.0 / 5 (0 votes)