The Six Steps of Steel Manufacturing

Summary

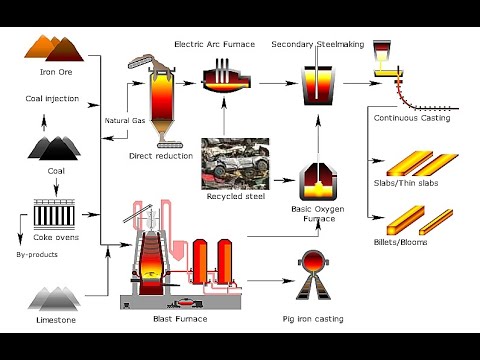

TLDRThis video explains the six-step process of steel manufacturing, starting from making iron in a blast furnace to the final shaping and treatment of steel. The process includes primary and secondary steel making, casting, primary and secondary forming, each crucial for achieving specific steel grades and shapes. The video also highlights the importance of high-quality equipment for steel mills, featuring products by Dixon that support steel processing. The viewer is encouraged to visit the company website for more information and subscribe to the channel for further updates.

Takeaways

- 😀 Steel is one of the most common materials used in everyday life, alongside plastic and paper.

- 😀 The steel manufacturing process can be divided into six key steps.

- 😀 Step 1: Making iron—molten iron is created by combining limestone, coke, and iron ore in a blast furnace.

- 😀 Step 2: Primary steel making—molten iron is processed in a basic oxygen furnace or electric arc furnace, where impurities are removed.

- 😀 Step 3: Secondary steel making—steel composition is refined using techniques like stirring and ladle injections to create different grades.

- 😀 Step 4: Casting—steel is cast into molds to cool, setting its shape and creating a thin, hard shell.

- 😀 Step 5: Primary forming—steel is further shaped and molded into flat sheets, beams, wires, or thin strips using hot rollers.

- 😀 Step 6: Secondary forming—final shaping of steel is done through methods like shaping, machining, joining, coating, and heat treatment.

- 😀 Steel can be customized into various grades, which are determined by the elements that remain in the steel at the end of manufacturing.

- 😀 The steel manufacturing process requires high-quality equipment due to the harsh conditions in steel mills, such as extreme temperatures.

- 😀 Dixon offers specialized products for steel mills, including GSM armored hose, quick disconnects, and swivels, to support the steel processing market.

Q & A

What is the first step in the steel manufacturing process?

-The first step is making the iron. Steel is forged from iron and carbon, so the process begins by creating molten iron from limestone, coke, and iron ore in a blast furnace.

What role do the basic oxygen furnace and electric arc furnace play in steel production?

-Both the basic oxygen furnace and electric arc furnace are used in primary steel making. In the basic oxygen furnace, steel scraps are mixed with molten iron, and oxygen is forced through to remove impurities. The electric arc furnace uses electricity to push impurities to the surface, refining the molten iron into raw steel.

What is secondary steel making, and how is it done?

-Secondary steel making is a process that refines the composition of the steel to create specific grades. This is achieved through techniques like stirring and ladle injections, which modify the elements remaining in the metal after primary refining.

What happens during the casting step of steel manufacturing?

-During casting, molten steel is poured into molds to cool. This process shapes the steel and forms a thin, hard shell on the surface. The steel strands are malleable and can be worked into different shapes such as bloom, billet, or slab.

What is the purpose of primary forming in steel manufacturing?

-Primary forming continues the shaping process started during casting. A hot roller fine-tunes the shape of the steel, molding it into its desired form and surface finish, such as flat sheets, beams, wires, or thin strips.

How does secondary forming affect the final steel product?

-Secondary forming is the final step in the steel manufacturing process. It refines the steel into its final shape and properties using methods like shaping, machining, joining, coating, heat treatment, and surface treatment.

What types of products can be made from steel after secondary forming?

-After secondary forming, steel is fully shaped and ready for use in a variety of applications. It can be processed into many products, including construction materials, automotive parts, and consumer goods.

Why is high-quality equipment necessary in steel mills?

-Steel mills operate in harsh environments with extreme temperatures, which puts a lot of strain on the equipment. High-quality, durable equipment is necessary to withstand these conditions and ensure efficient and safe operations.

What types of products does Dixon offer for steel mills?

-Dixon offers a variety of products for steel mills, including GSM armored hoses, quick disconnects, swivels, cam & groove fittings, and more.

Where can I find more information about products for steel processing?

-You can find more information about products for steel processing on Dixon's website, specifically on their steel processing market page.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

5.0 / 5 (0 votes)