Sand Casting

Summary

TLDRThis video provides a detailed overview of the sand casting process. It starts with the creation of top and bottom patterns, followed by adding feeds and risers. The sand boxes are filled and vibrated to ensure the proper shape is embedded. After the patterns are removed, the two sand boxes are aligned with dowel pins, and molten metal is poured into the mold. Once cooled, the part is removed, and the feeds are cut off. The video offers a clear, step-by-step look at how sand casting works to create metal parts.

Takeaways

- 😀 Sand casting involves creating patterns for the top and bottom halves of the mold.

- 😀 Feeds and risers are added to one side of the patterns to ensure proper metal flow.

- 😀 Metal or wooden sand boxes are placed over the patterns to form the mold.

- 😀 Sand is poured into both halves of the mold, typically followed by vibration to ensure the sand settles.

- 😀 The sand is then compressed to create a solid mold structure.

- 😀 The sand boxes are flipped upside down, and the patterns are removed, leaving the shape of the part in the sand.

- 😀 Dowel pins are used to align the top sand box with the base sand box.

- 😀 Molten metal is poured into the mold, filling the embedded pattern.

- 😀 The molten metal is allowed to solidify and cool, forming the part inside the mold.

- 😀 Once cooled, the dowel pins are removed, revealing the molded part with the feed still attached.

- 😀 The feed is cut off from the part, leaving the finished casting ready for use.

Q & A

What is the purpose of sand casting patterns?

-The purpose of sand casting patterns is to create the shape of the part that will be molded in the sand, allowing for the creation of a casting in metal.

Why are feeds and risers added to one side of the sand patterns?

-Feeds and risers are added to ensure proper flow of molten metal and compensate for shrinkage during cooling, helping to maintain the quality of the final part.

What role do sand boxes play in the sand casting process?

-The sand boxes are placed over the patterns to hold the sand in place and provide a controlled environment for the molding process.

How is the sand prepared for the casting process?

-The sand is poured into the sand boxes and then vibrated and compressed to ensure a solid and stable mold for the molten metal.

What happens after the sand boxes are filled with sand?

-Once the sand boxes are filled, they are turned upside down, and the patterns are removed, leaving the shape of the part embedded in the sand.

Why are dowel pins used in the sand casting process?

-Dowel pins are used to align the two halves of the sand mold precisely when they are placed together, ensuring that the mold halves fit perfectly during metal pouring.

What happens after the molten metal is poured into the sand mold?

-The molten metal is poured slowly into the mold until it fills the cavity, after which the metal solidifies and cools, forming the shape of the part.

How do you know when the metal has cooled enough to be removed from the mold?

-The metal is fully cooled when it solidifies and reaches a temperature where it can be safely handled and removed from the mold.

What is done with the molded part after it cools?

-After the metal has cooled, the dowel pins are removed, and the molded part with the feed is visible, allowing it to be extracted from the mold.

What is done with the feeds once the part is removed from the mold?

-The feeds are cut off from the part, leaving the final, finished casting ready for use.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

Casting Metal: showcasing the basics of casting and the Casting is the future Foundry Kit

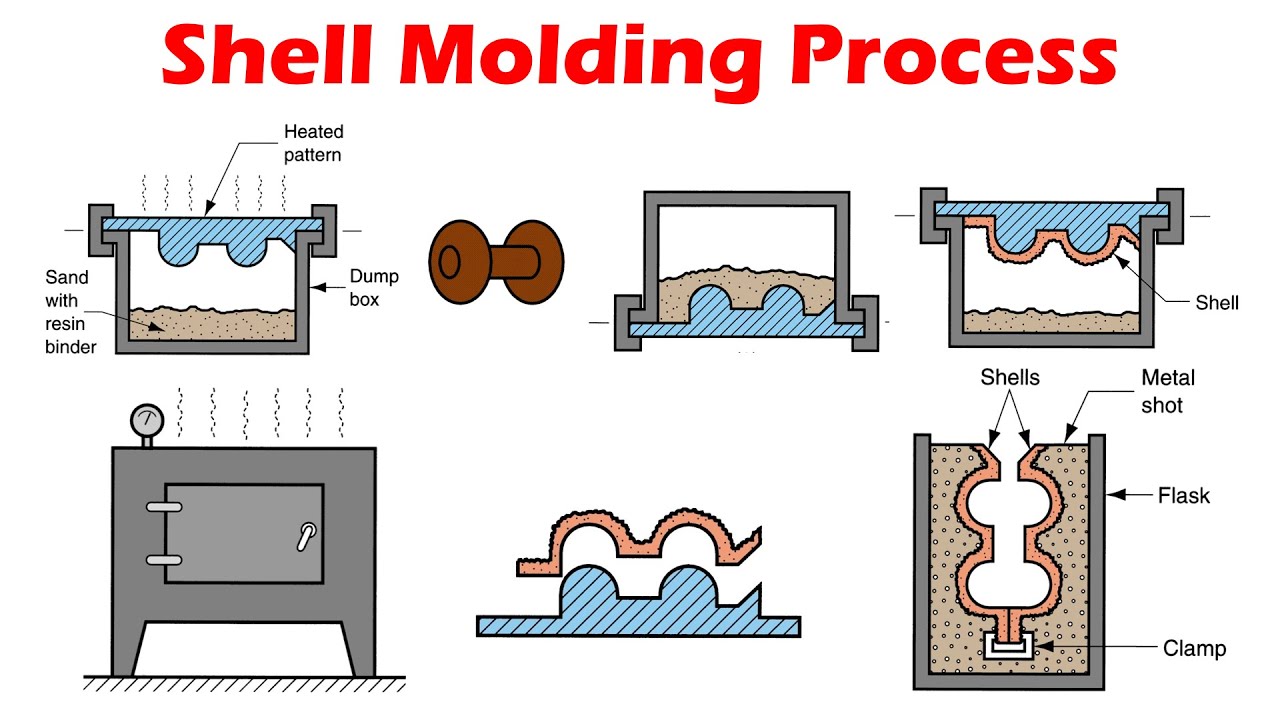

Shell Molding - Expandable Mold Casting Processes

What Are The Common Types Of Metal Casting Process In Engineering and Industry?

How to make a propeller sand mold

Proses Tuangan Logam Sand Casting Part 1

PENGECORAN LOGAM | Praktikum MK Teknologi Manufaktur

5.0 / 5 (0 votes)