plc

Summary

TLDRThis video explains how a PLC (Programmable Logic Controller) converts an analog input voltage into binary code, with a focus on how resolution impacts the accuracy of this conversion. The speaker demonstrates the effect of different bit resolutions (4-bit, 12-bit, and 16-bit) using a simulator, showing how the number range expands as the resolution increases. A practical example is provided, highlighting the need for higher resolution in processes like chemical production, where precise temperature measurements are crucial. The video concludes by reinforcing the importance of resolution for accuracy in various industrial applications.

Takeaways

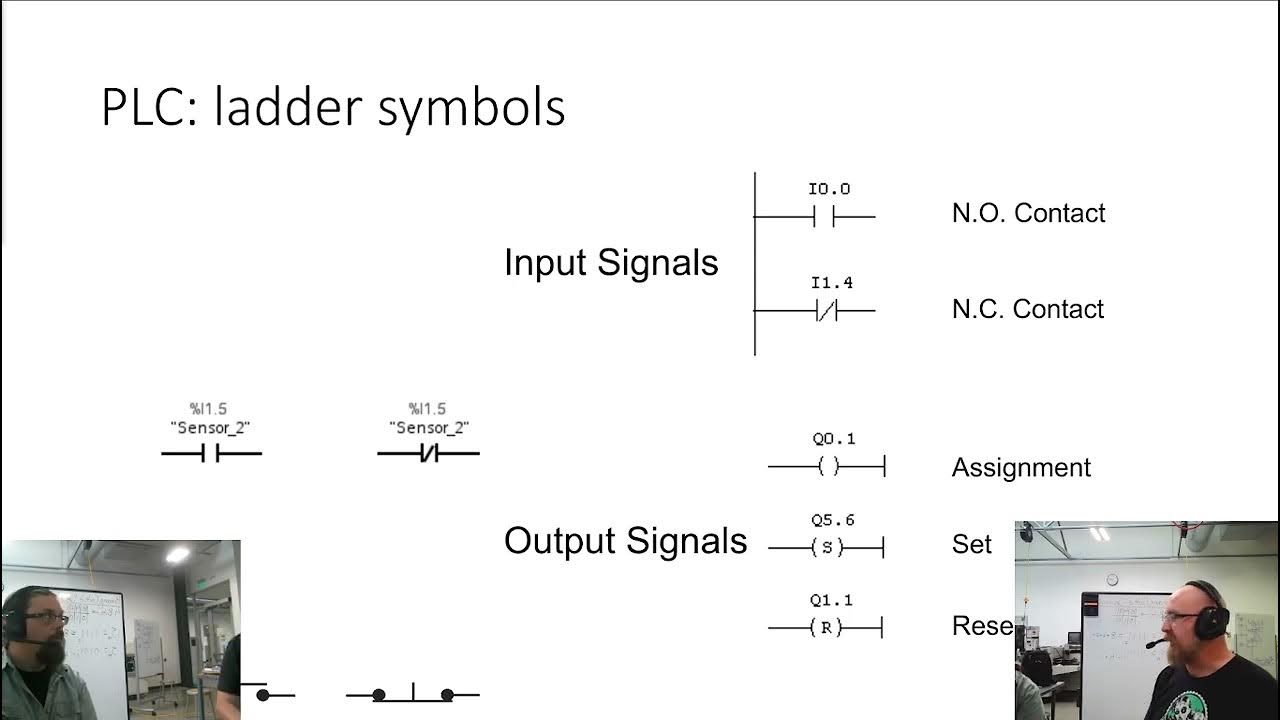

- 😀 The PLC reads the input voltage at the analog input terminals and converts it into binary code.

- 😀 The resolution of the PLC's analog input can be adjusted to determine the level of precision when converting the voltage into a number.

- 😀 In the software simulator, the resolution can be changed to observe how it affects the range of values that can be represented for a 0 to 10V input.

- 😀 When the resolution is set to 12 bits, the PLC can represent values from 0 to 4,095, corresponding to the 0 to 10V range.

- 😀 Reducing the resolution to 4 bits limits the range of numbers to 0 to 15, as 4 bits in binary code can only represent 16 values.

- 😀 Changing the resolution to 16 bits increases the range of numbers from 0 to 65,535, offering much more precision in voltage measurements.

- 😀 The PLC uses unsigned integers for the input values, meaning the range of values goes up to a positive number (e.g., 65,535) without including negative values.

- 😀 The choice of resolution impacts the accuracy of the measurement. For example, to detect 40 different temperature points accurately, a higher resolution is necessary.

- 😀 Lower resolution (like 4 bits) provides insufficient accuracy for processes that require precise measurements, such as detecting various temperature-dependent products in a chemical process.

- 😀 The resolution setting should match the level of accuracy required for a given application, and greater resolution allows for more precise control and detection of small variations in input signals.

- 😀 The key takeaway is that understanding and adjusting the resolution in a PLC system is vital for ensuring precise measurements in real-world processes.

Q & A

What happens when the PLC receives an input voltage at the analog input terminals?

-The PLC converts the input voltage to binary code, which is then represented as a numerical value corresponding to the binary code.

How does the resolution setting affect the PLC's handling of analog input?

-The resolution setting determines how finely the PLC can break up the voltage range (0 to 10V) into numerical values. Higher resolution provides more accurate and detailed representation of the input signal.

What does a resolution of 12 bits mean in the PLC software simulator?

-A resolution of 12 bits means the PLC can represent the 0 to 10V range using 4096 distinct values (from 0 to 4095).

What happens when the resolution is reduced to 4 bits?

-When the resolution is set to 4 bits, the PLC can only represent the 0 to 10V range using 16 values (from 0 to 15).

What is the maximum value the PLC can represent with 16-bit resolution?

-With a 16-bit resolution, the PLC can represent the 0 to 10V range using values from 0 to 65,535.

Why do we need higher resolution when working with processes requiring precision, like in the chemical industry?

-Higher resolution allows for greater accuracy in detecting small changes in input values, which is essential when monitoring precise parameters like temperature, which can directly impact the production of different products.

Why is using only a 4-bit resolution inadequate for detecting multiple temperature points in a chemical process?

-A 4-bit resolution provides only 16 distinct values, which is insufficient for accurately monitoring processes that require a higher number of distinct measurements, such as detecting 40 different temperatures.

What is the significance of using unsigned integers in the PLC resolution?

-Unsigned integers allow the PLC to represent only positive numbers, which is why the range extends from 0 to the maximum value (e.g., 65,535 for 16 bits), as opposed to signed integers, which would include negative values.

What does the speaker suggest doing after playing around with the resolution settings in the simulator?

-The speaker suggests changing the resolution back to 12 bits and saving the settings before moving on to the next lesson.

How does the concept of resolution relate to practical applications like monitoring chemical processes?

-In practical applications, higher resolution allows for more accurate monitoring of variables such as temperature, enabling the detection of subtle changes that could be critical in processes that require precision, such as chemical reactions.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

5.0 / 5 (0 votes)