Plastic Injection Molding

Summary

TLDRPlastic injection molding is a widely used method for manufacturing plastic products. The process involves melting plastic pellets and injecting the molten material into a mold cavity. The plastic solidifies as it cools, taking the shape of the mold. Key steps include heating the pellets, injecting the material, and then cooling and ejecting the finished part from the mold. This efficient process ensures high precision in producing plastic components, making it ideal for mass production.

Takeaways

- 😀 Plastic injection molding is a common method for mass manufacturing plastic products.

- 😀 The principle of plastic injection molding involves injecting molten plastic into a mold cavity, where it cools and solidifies into the mold's shape.

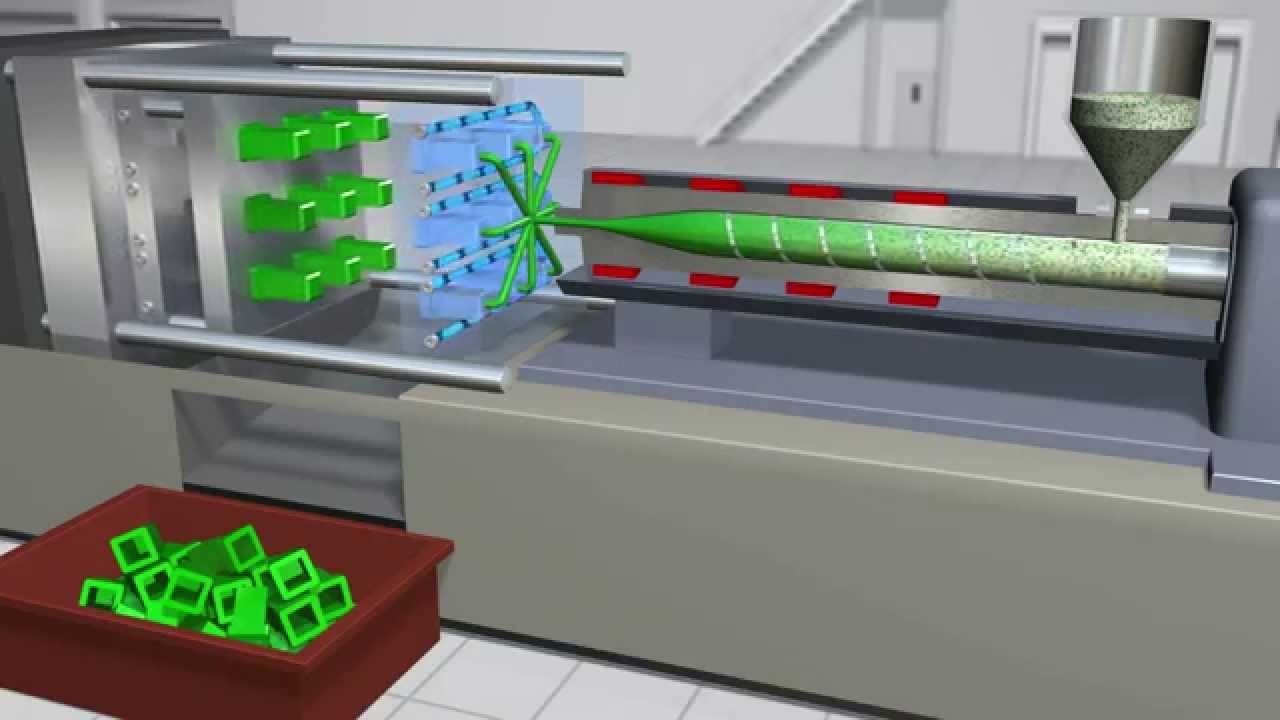

- 😀 The process involves three main components: the injection machine, the plastic injection mold, and the plastic pellets.

- 😀 Plastic pellets are loaded into the hopper at the back of the injection machine, where they are transported and melted in the heated barrel.

- 😀 The screw inside the machine moves the melted plastic into the mold cavity for shaping.

- 😀 The mold's temperature is controlled by a temperature controller, which ensures it is cooler than the barrel temperature, allowing the plastic to solidify quickly.

- 😀 After cooling, the mold opens, and the clamping plate of the injection machine moves backward.

- 😀 The ejector plate pushes the molded part out of the mold after it has cooled and solidified.

- 😀 The process ensures that each part is precisely formed and easily removed from the mold.

- 😀 The efficiency of the injection molding process allows for the mass production of uniform plastic parts.

Q & A

What is the primary method for mass manufacturing plastic products?

-The primary method for mass manufacturing plastic products is injection molding. It involves injecting melted plastic into a mold cavity, allowing it to cool, and then solidifying into the shape of the cavity.

How does the injection molding process work?

-In injection molding, melted plastic is injected into a mold cavity where it cools and solidifies into the shape of the cavity. This process requires an injection machine, a mold, and plastic pellets.

What is the role of the hopper in the injection molding process?

-The hopper is responsible for feeding plastic pellets into the injection machine. These pellets are then transported and melted to be injected into the mold.

How is the plastic material heated in the injection molding process?

-The plastic pellets are heated by a rotating screw inside the injection machine. This screw gradually melts the plastic as it moves toward the front of the machine.

What happens once the plastic is melted in the injection molding machine?

-Once the plastic is sufficiently melted, it is injected into the mold cavity by the rotating screw under high pressure.

Why is the mold temperature controlled in the injection molding process?

-The mold temperature is controlled to ensure that the molten plastic solidifies at the correct rate. The mold is kept at a lower temperature than the barrel to allow the plastic to solidify quickly.

What occurs after the plastic is injected into the mold cavity?

-After the plastic is injected, the mold is allowed to cool and solidify the plastic. The mold then opens, and the part is ejected from the mold.

How is the part ejected from the mold after cooling?

-The part is ejected using an ejector plate that is pushed by the injection machine's push bar once the mold opens.

What is the function of the clamping plate in the injection molding process?

-The clamping plate is responsible for holding the mold closed during the injection of the molten plastic and is moved backward after the molding process is complete.

What happens when the mold opens in the injection molding process?

-When the mold opens, the plastic part is ejected using the ejector plate. This allows the part to be removed from the mold and the process to begin again.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тариф5.0 / 5 (0 votes)