02_06_P1 Three Types of Layouts: Process, Product, and Fixed Position

Summary

TLDRThis lecture on work and process design focuses on understanding the relationship between process types and facility layouts. It explores various layout types, including process, product, fixed position, and cellular layouts, emphasizing their interconnection with different production processes like jobbing, batch, mass, and continuous. The session also highlights the importance of efficiency, flexibility, and balancing in design decisions, offering practical examples and key advantages and disadvantages of each layout. Special attention is given to cellular layouts in lean manufacturing, emphasizing waste reduction and process optimization.

Takeaways

- 😀 The layout design is crucial for ensuring a smooth flow of work, material, people, and information through the system.

- 😀 The type of layout chosen strongly depends on the process type being used, and understanding this relationship is essential.

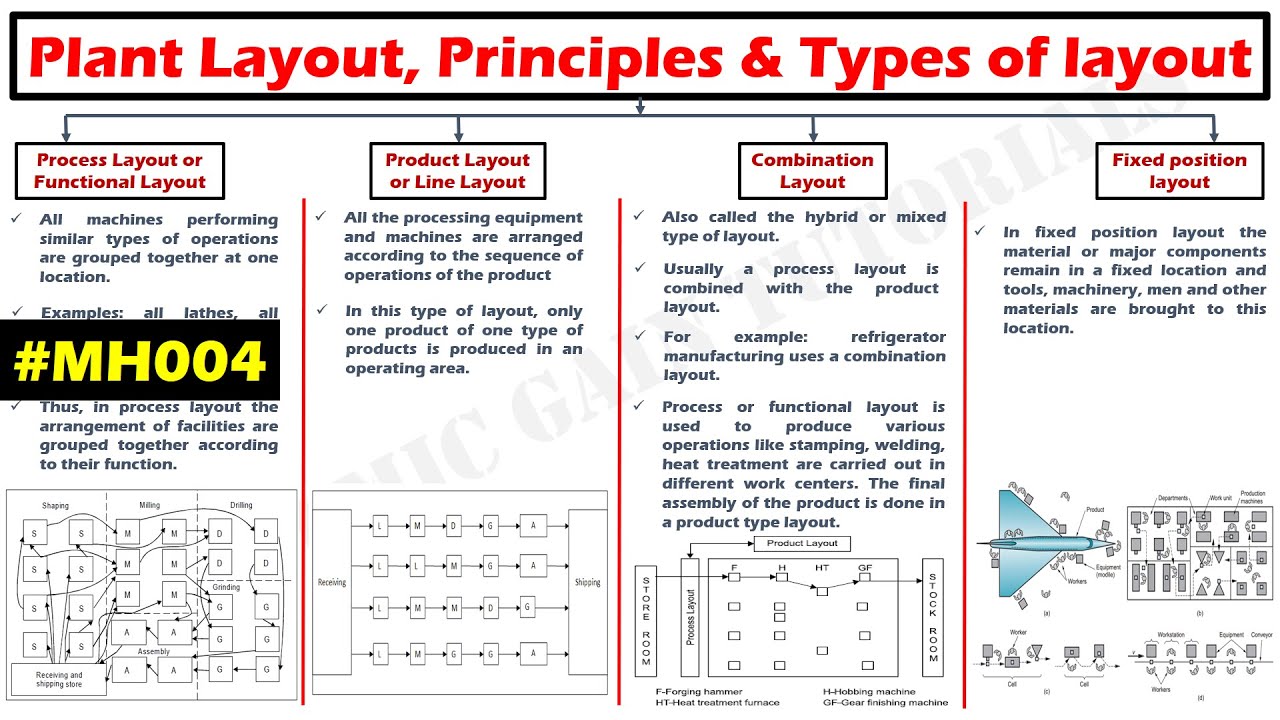

- 😀 There are three basic types of layouts: Process Layout, Product Layout, and Fixed Position Layout.

- 😀 Process Layout (Functional Layout) groups activities according to similar functions and is ideal for low-volume, high-variety production.

- 😀 Product Layout arranges activities in a sequence based on the product's production steps, typically used in mass production with high volume and low variety.

- 😀 Fixed Position Layout is used when the product cannot be moved (e.g., large projects like ships or airplanes), and resources are brought to the product.

- 😀 A cellular layout is a hybrid layout used in lean manufacturing, focusing on reducing waste and improving efficiency.

- 😀 Job shops and batch production processes typically use Process Layout or Cellular Layout, while mass and continuous processes use Product Layout.

- 😀 Process Layout is highly flexible but suffers from inefficiencies like high transportation time, backtracking, and fluctuating worker load.

- 😀 Product Layout is efficient and suitable for assembly lines but lacks flexibility, with concerns about line balancing and adapting to production changes.

- 😀 Fixed Position Layout focuses on completing large projects within a specified timeframe and budget, with scheduling and time constraints being significant challenges.

Q & A

What is the primary goal of facility layout design?

-The primary goal of facility layout design is to ensure a smooth flow of work, materials, people, and information through the system, minimizing inefficiencies and optimizing space utilization.

How does the type of process influence the choice of layout?

-The type of process—whether project, jobbing, batch, mass, or continuous—affects the layout choice because different processes require different flows of materials, resources, and workstations. For example, project processes often use fixed-position layouts, while mass production uses product layouts.

What is a process layout and where is it typically used?

-A process layout, also known as a functional layout, groups machines and equipment by their function. It is used in environments where products have varying needs, such as job shops and batch production, providing flexibility but causing inefficiencies in material handling.

What are the major advantages of process layouts?

-The major advantages of process layouts include flexibility in accommodating different products and customization, as well as the ability to easily switch between various tasks and production requirements.

What are the primary disadvantages of process layouts?

-The primary disadvantages of process layouts are inefficiencies such as low resource utilization, high backtracking and transportation time, and frequent changes in setup requirements for different products.

What is a product layout, and when is it most beneficial?

-A product layout arranges workstations and activities in a line according to the sequence of operations needed to assemble a specific product. It is most beneficial in high-volume, mass production environments where the demand for a standardized product is stable.

What challenges are typically associated with product layouts?

-The main challenges associated with product layouts are inflexibility, as each line is dedicated to a specific product, and the need for line balancing to ensure that no workstation becomes a bottleneck in the production process.

What is the key difference between process layouts and product layouts in terms of inventory?

-In a process layout, work-in-progress inventory is typically high, while finished goods inventory is low. In contrast, a product layout typically has low work-in-progress inventory and high finished goods inventory.

How does a fixed-position layout differ from process and product layouts?

-A fixed-position layout is used when the product is too large or heavy to be moved, such as in shipbuilding or aircraft manufacturing. In this layout, resources, labor, and equipment are brought to the stationary product, whereas process and product layouts involve moving products through different workstations or production lines.

Why is cellular layout important in lean manufacturing?

-Cellular layout is important in lean manufacturing because it groups machines into cells dedicated to a specific product, reducing waste and improving flow efficiency. It is highly flexible and can be adapted to different product families, making it ideal for minimizing waste and improving overall efficiency in manufacturing systems.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

5.0 / 5 (0 votes)