What is Six Sigma?

Summary

TLDRThis video introduces Six Sigma, a process-improvement methodology aimed at reducing variation and embedding quality into processes. It explains that Six Sigma focuses on producing fewer than 3.4 defects per million opportunities, aiming for consistency and repeatability. The video also differentiates Six Sigma from Lean and Continuous Improvement, and explores its origins with companies like Motorola and General Electric. Through examples like golf and baking, it highlights how reducing process variation leads to better quality and fewer defects, ultimately benefiting customer satisfaction and long-term success.

Takeaways

- 😀 Six Sigma focuses on process improvement by reducing variation to ensure consistent results and high quality.

- 😀 A process is a set of related activities that require resources (people, methods, materials, equipment, and time) to achieve outcomes.

- 😀 Six Sigma aims for processes to have as little variation as possible, targeting less than 3.4 defects per million.

- 😀 Lean focuses on eliminating waste to maximize customer value, while Six Sigma is about reducing variation and improving quality.

- 😀 Kaizen (continuous improvement) represents the ongoing effort to reduce waste and improve processes toward lean efficiency.

- 😀 Lean Six Sigma combines Lean principles (waste reduction) with Six Sigma methods (quality and variation reduction).

- 😀 Six Sigma is not a destination, but a continuous journey to reduce variation and improve process capabilities.

- 😀 In statistical terms, Six Sigma means a process that produces results with minimal variation from the average.

- 😀 A visual example with golf illustrates how the consistency of a process improves from one sigma to six sigma.

- 😀 Six Sigma is practical and considered world-class, although it may not be achievable for all processes, especially those with inherent variability.

- 😀 The concept of Six Sigma emphasizes that every process can improve its consistency and quality, but not all processes are capable of reaching Six Sigma levels.

Q & A

What is Six Sigma?

-Six Sigma is a problem-solving methodology aimed at reducing process variation and improving quality. It focuses on achieving less than 3.4 defects per million opportunities in a process.

What are the key components of a process in Six Sigma?

-A process in Six Sigma involves various activities that are interrelated and organized. It uses resources such as people, methods, materials, equipment, and time to achieve consistent results.

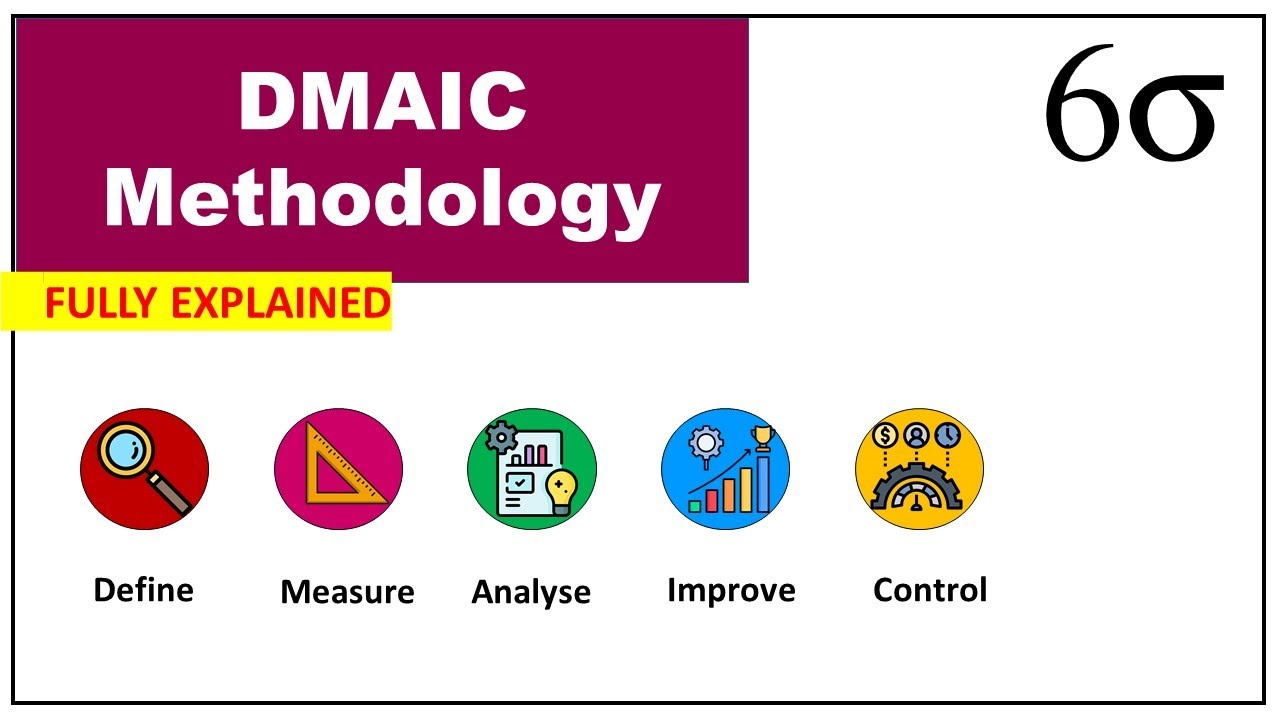

How does Six Sigma aim to improve processes?

-Six Sigma aims to reduce variability within processes, making them more capable, repeatable, and consistent, which results in better quality and fewer defects.

What is the difference between Lean, Six Sigma, and Continuous Improvement?

-Lean focuses on reducing waste to maximize customer value. Six Sigma focuses on reducing variation and improving quality. Continuous Improvement (Kaizen) is the philosophy of continually striving for better efficiency and reduced waste.

What is the meaning of 'Six Sigma' in statistical terms?

-In statistics, 'Six Sigma' refers to a process that operates within six standard deviations from the mean, ensuring that defects are minimized to less than 3.4 per million opportunities.

How does Six Sigma apply to a real-world example like golf?

-In golf, a beginner's performance is inconsistent (1 Sigma), while a more advanced player hits shots within a tighter range (higher Sigma). A Six Sigma golfer has minimal variation, hitting the ball consistently within the desired range.

Why is Six Sigma considered world-class?

-Six Sigma is considered world-class because it represents a process with very low variation, resulting in high consistency and quality, which translates into fewer defects and greater customer satisfaction.

Can all processes become Six Sigma capable?

-No, not all processes are capable of reaching Six Sigma levels. Some manual or craft-based processes have inherent variability that cannot be reduced to this level.

How does Six Sigma impact the quality of products or services?

-By reducing process variation, Six Sigma ensures that products or services are more consistent, leading to fewer defects, rework, and customer complaints, which boosts overall long-term success.

Is Six Sigma always the best solution for every industry?

-Not necessarily. While Six Sigma offers significant benefits in many industries, it may not be suitable for all situations. For example, in industries where safety is critical (like aviation), a defect rate of 3.4 per million might not be acceptable.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

5.0 / 5 (0 votes)